Latest Blogs

10 Most Popular Injection Molding Materials

What are the most popular injection molding materials? Acrylic (PMMA) Acrylonitrile Butadiene Styrene (ABS) Nylon polyamide (PA) Polycarbonate (PC) Polyethylene (PE) Polyoxymethylene (POM) Polypropylene (PP) Polystyrene (PS) Thermoplastic Elastomer (TPE) Thermoplastic Polyurethane (TPU) We often get asked which plastic resins are the best choice for a client’s project. To answer it simply — there is […]

Read more

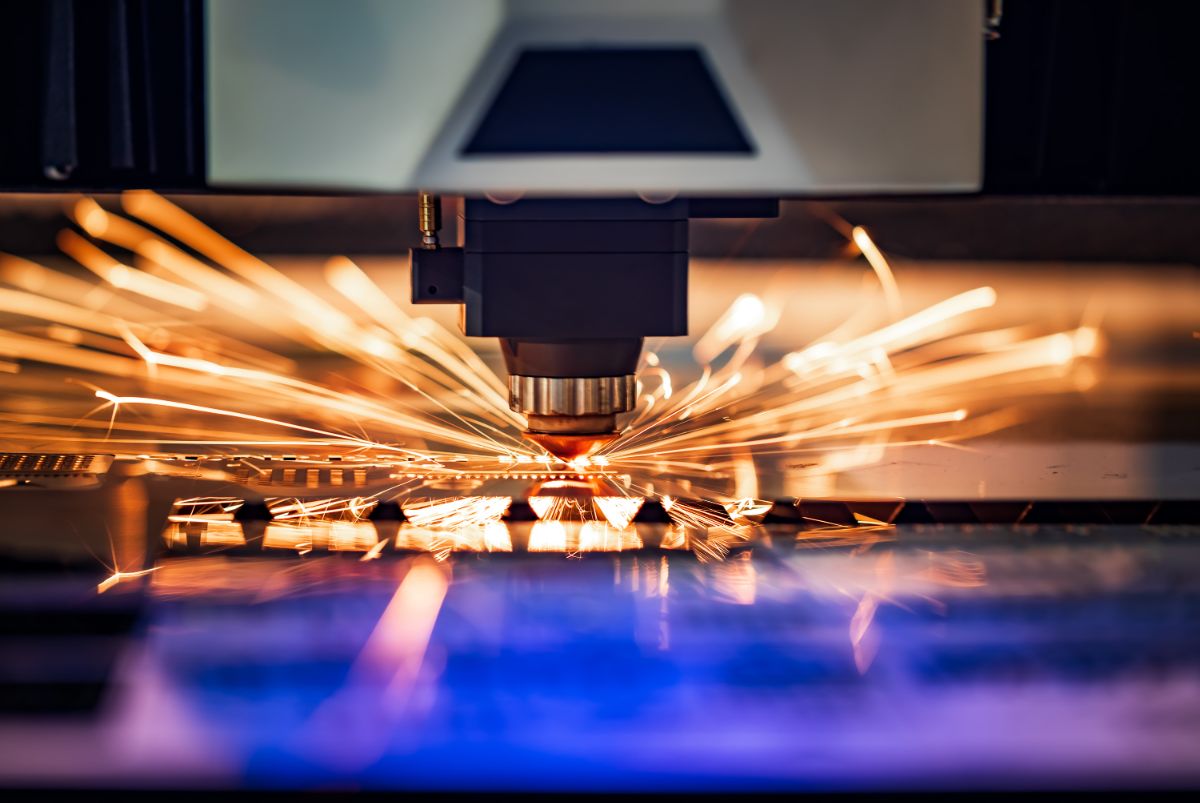

Why Air Assist is Essential To Your Laser Engraver?

Why is air assist essential to laser engraver? It improves efficiency It is a good investment for businesses It reduces the production cost It gives high-edge quality It gives cleaner finishing It increases safety If you want an improved product surface texture while also reducing the use of plastic materials, applying an air assist is […]

Read more

How To Know If Overmolding Or Insert Molding Is Better For Your Project?

How to know if overmolding or insert molding is better for your project? Projects For Electrical Industry Projects For Automotive Industry Projects For Consumer Goods Projects For Beauty Industry Projects For Medical Industry When it comes to determining the best plastic injection method for your project, there are two primary choices: overmolding and insert molding. […]

Read more

5 Ways to Optimize Large Part Injection Molding

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read moreOther Blogs

Uses of High Strength Injection Molded Plastics

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more

Is Your Injection Molder Sustainable?

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more

Questions to Ask Your Molding Company China

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more

Injection Molding China: Custom Molding Tips

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more

Injection Molding vs 3D Printing: Which is Better?

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more

The Five Parameters of Injection Molding: Its Positive Impacts

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more

How to Set Barrel Temperatures of Injection Molds from China

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more

All About Injection Molds in China and Polycarbonate Plastics

What are the different ways to optimize large part injection molding? Use a sample batch to do quality control Examine and test the mold Test the tools and make adjustments Process the performance ranges and parameters Follow a design of experiments There are many complexities in the process of plastic injection molding even when producing […]

Read more