What process improvements should injection molds in China utilize for your business?

- Material considerations

- Gate location

- Special features

- Adjust the formulation

- Optimize run size

- Supervising production rates

- Scrap reduction

- Mold preventative maintenance

The right injection mold from China will make a great difference in terms of your business’ improvements for product manufacturing. Plastic manufacturing companies understand that they should readily comply with your goals for improvements to accomplish your target in terms of production. With that, you should be knowledgeable about the ways that can help you achieve this purpose as well. You can read more about it right here:

Material Considerations

In order to improve the injection mold process, you should never neglect material considerations. Choosing from a wide range of plastics resins that are adequate to the whole molding process should be your top priority. This is greatly attributed to improving the whole manufacturing process for your business. Material considerations include temperature, chemical resistance, assembly, cost, availability, and agency approvals.

There should be a prime consideration for ensuring that the material is optimized for the end-product in mind. Manufacturing, maintenance, assembly, and disassembly will bring out functional and appearance values which will lead to more advantages for business purposes. The resin material ultimately dictates how the product can follow design and engineering requirements. This gives way to accomplishing improvements in labor, tooling, finishing, and other considerations.

Gate Location

What you should know about improving the manufacturing process of injection molding is that gate location provides a critical contribution to it. The gate refers to the opening in a mold where the molten plastic is injected into the final part. The type of gate and its placement provides value to the part’s overall quality and viability. It is important to note that the gate location is one of the most critical aspects of the mold design.

Special Features

Molding machines should be made to produce plastic parts easily. Special features like holes, undercuts, or shoulders can prevent defects and it can also give you the flexibility to incorporate other techniques into the design. Improving the injection mold process should be helmed by an experienced team of molders and engineer to avoid issues in design and development. Proper alignment with the goal of utilizing special features will go a long way and improving the production process is key. The end result may lead to shorter setup times, scrap reduction, preventative maintenance, and optimum run size.

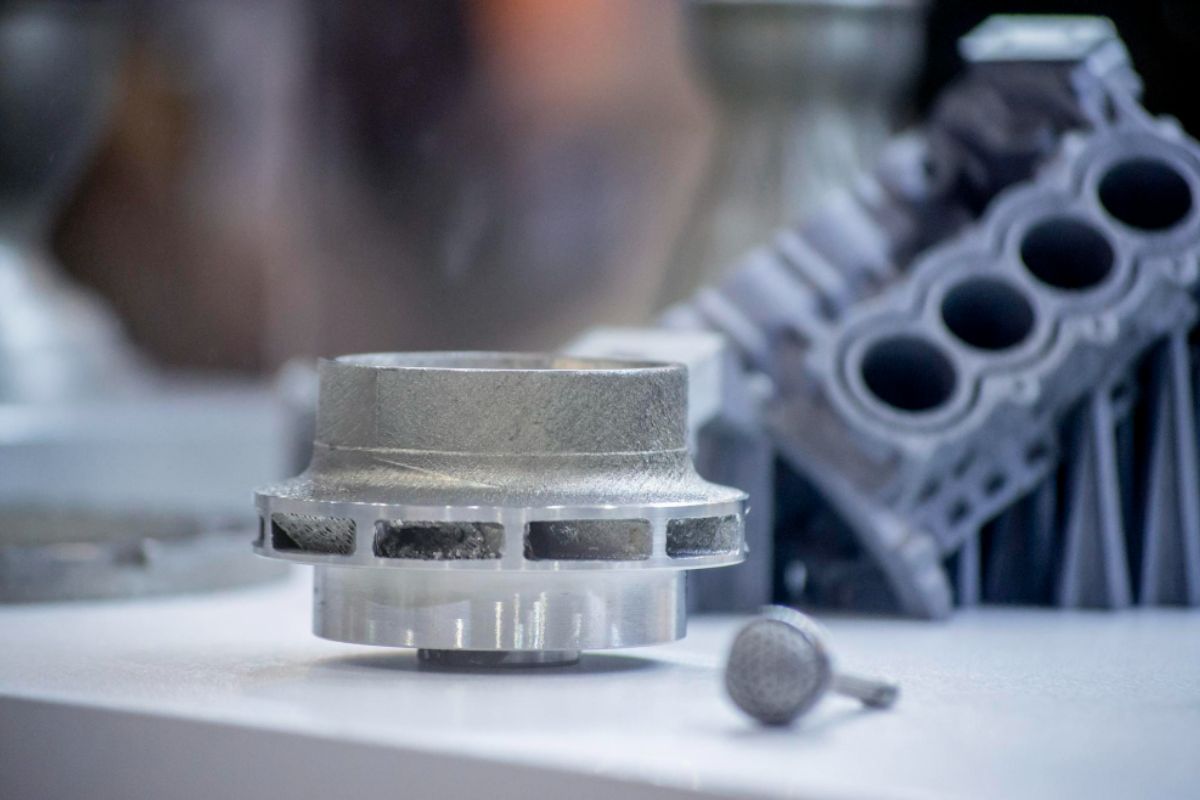

Adjust the Formulation

The dimensions you would want for your design can be based solely on the adjusted formulation you have in the injection mold design. Adjusting the mold design will enable you to get the dimension you would want based on the projected shrinkage that will occur during production. This means that you have to ask your injection mold team to optimize parameters such as the molding temperature, melt temperature, and injection speed, mold pressure, and cooling time.

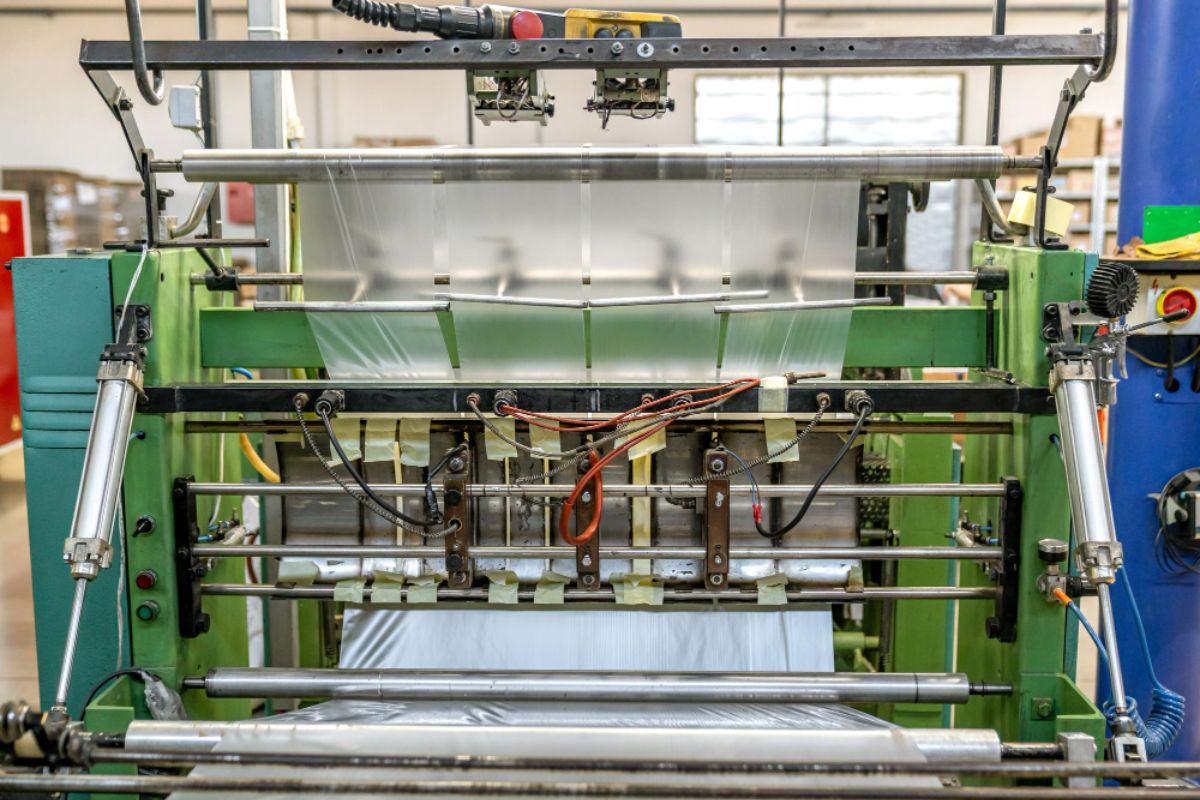

Optimize Run Size

Plastic injection molding machines should run consistently with the supervision of an engineering and design team. Improving the injection mold process is also closely attributed to the consistent optimization of the technicalities of the part production. The machines that are running constantly should be monitored to optimize run size so you can incur fewer costs in manufacturing.

Supervising Production Rates

In line with optimizing run size, you should always keep in mind that supervising production rates will be beneficial to the manufacturing of plastic parts. Monitor the team that is assigned to your project and see to it that they work on it as efficiently as possible. Reward them as you see fit because this can influence enthusiasm and interest in the project, therefore, allowing the team to work harder for the products required of your business.

Scrap Reduction

You may think that scraps are not integral to the production process, but they are also an important part of improvement. It should be factored in because scrap can function as a supplement to the production rate and labor expenditure. The cost of the production also covers material loss so you have to keep a close eye on this variable that can improve the production process. Monitor and control the scraps; you may not know it, but it can also be an addition to the improvement of the manufacturing process. The end goal of this consideration is to reduce the scraps and ultimately, form the perfect part.

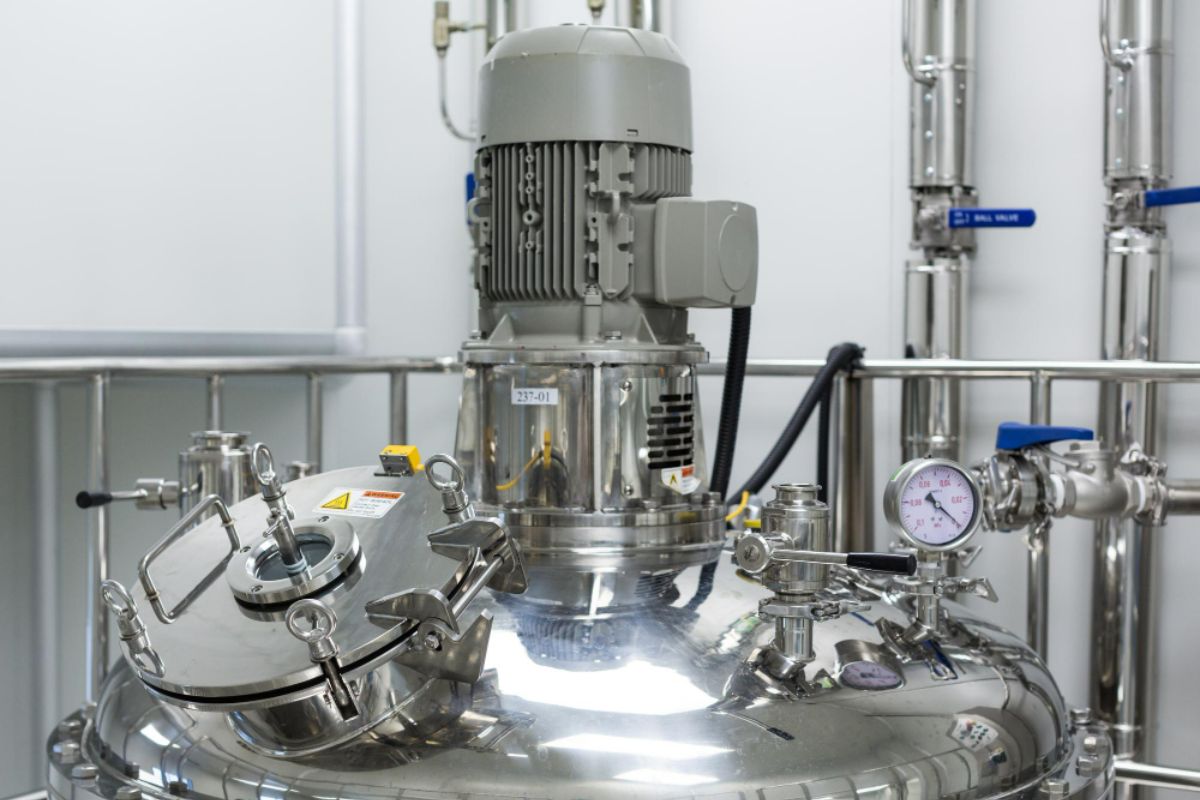

Mold Preventative Maintenance

Maintenance of the molds should be greatly considered when seeking the improvement of the molding process. Very important issues arise from preventive maintenance and how the injection molder complies with it. It would be more efficient if the preventive maintenance is dealt with and scheduled when the manufacturing process is at the state of rest so that it will be taken care of with much attention and detail.

Key Takeaway

The benefits that injection molds in China can give you will generate astounding results. With its capabilities to maximize improvements for your business, you will not be inclined to look for other plastic manufacturing companies in the industry. Ask your injection molding team about the methods listed above so you can work hand in hand with them to achieve effective design standards.