What are the factors to consider when choosing a plastic mold maker?

- Customer service and communication

- Compliance with specifications

- Offered services and technology

- Quality and efficiency

- Value

- Years of experience

Selecting the right plastic injection mold maker can be challenging — but it doesn’t have to be. The most important part of finding the right partner for your project is knowing what qualities to look out for, and what services they need to provide. And, in this post, we’ll cover what those are. Here are the six key factors to consider when choosing a plastic mold maker:

Customer service and communication

Working with a mold maker is likely going to be the start of a long-term partnership, which means that the company you consider needs two critical capabilities. These are exceptional customer service and clear and consistent communication.

This is vital, especially with complex mold designs, or projects that have a high level of intellectual property sensitivity. These two qualities will ensure that your partner is responsive to your needs and that their mold-making process is proceeding as it should be.

Be sure to ask your contact to walk you through the mold-making process — from placing your order, and through the whole series of manufacturing and delivery. And, pay attention if your contact can show a communicative process, and can break down any industry terms into language you can easily understand.

These are good signs that the company is professional, open to communication, and can include you in every step of development with ease.

Compliance with specifications

While it is a given that you will have to make concessions with your partnered mold maker, having to compromise too much might put you in a challenging situation.

Regardless of what designs you want for your plastic product, there is going to be a company that can balance practicality with the vision you have in mind. A good plastic injection mold maker can make strong recommendations to improve your design’s manufacturability and functionality, without asking you to make too many compromises.

These recommendations may include minor design tweaks, alternative resin suggestions, and other ways that can help you save time and money with your mold and your plastic injection molding process.

Offered services and technology

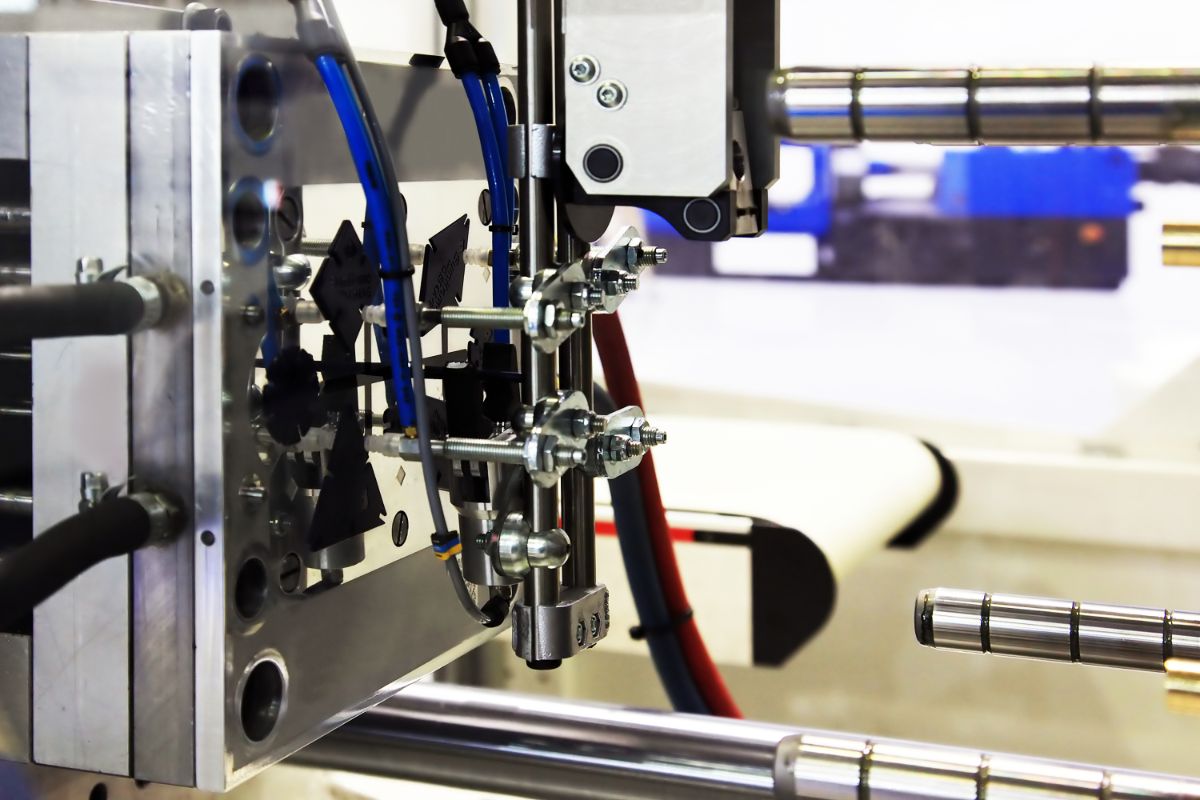

Not all mold makers have expanded services and technology to make durable, precise, and high-quality plastic molding and tooling.

So, selecting a plastic injection molding company that not only has a great design team to help you improve your mold but also has the capabilities to add to their mold-making process is important.

Working with a mold maker who offers services such as in-depth mold flow analysis, quick response manufacturing, several mold materials, part design services, and more will help you make your mold as cost-efficient as possible while meeting your exact design specifications.

Quality and efficiency

As we mentioned earlier, your injection molding partner needs to offer quality services, as well as efficiency when creating your requested mold.

Here are a few indicators of an injection mold maker that can offer you both of those qualities in their services:

- They own several high-quality and efficient machines with different capacities — all of which are maintained regularly and proven to work well.

- They are recognized in the industry as a reliable and reputable manufacturer. This can also be indicated by past industry rewards for performance and quality.

- They offer several secondary mold services, such as a robust mold maintenance program.

- They utilize project management software throughout the mold-making process, to ensure the highest level of efficiency and transparency at each step.

- They also embed strict inspections and quality checks throughout the process, to ensure that each mold they make meets high safety and quality standards.

- They are ISO certified, amongst other industry-relevant quality certifications.

Value

Price is always an important factor when choosing a partner for manufacturing — it’s part of staying within budget, and calculating the best return on investment.

However, always going for the bargain deals may cost you more in the long run. When it comes to mold making, many elements come into play when tallying up the overall price, including added services and design optimization.

Sometimes, a more costly investment just means you’re paying for good design and material selection, as well as valuable support from your mold-making team.

When receiving a quote, always consider the overall value of the mold and service being provided, as well as the mold maker’s ability to be a vital resource to you and your team before signing on or writing them off.

Years of experience

Many things will add to a mold maker’s ability to deliver an exceptional design and product, but the most important one will always be the years of experience they have in business.

When looking for a mold maker, always consider how long they have spent in the industry. Be sure to ask how long the company has been offering their mold-making services, and also ask what specializations or expertise they have.

Key Takeaway

Choosing the right mold maker is crucial to the success of your final plastic product. Keep these factors to consider when choosing a plastic mold maker in mind to find the right partner that can meet your specific needs, and understand your expectations and challenges.

If you’re looking for an experienced, quality-oriented mold maker that meets all these factors — and offers more benefits — then message Richfields today. We are an plastic injection molding company in China that offers mold-making services, and has been in the business for decades! Send us an inquiry, and we’ll be happy to walk you through what we offer in every stage of your part production.