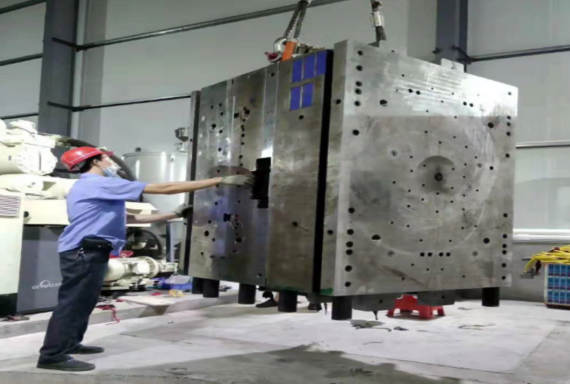

Large-part Injection Molding in China

Large-part injection molding in China is a specialized field in plastic manufacturing. It offers numerous advantages in producing large-scale plastic components. It is an innovative solution for any plastic item, from plastic pallets to car bumpers. As a sought-after service for making sizeable products, it is an ideal choice for businesses across various industries looking for reliable production capabilities.