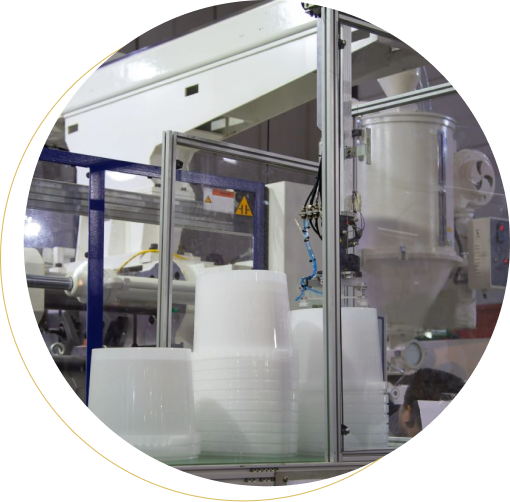

Plastic Mold Maker in China

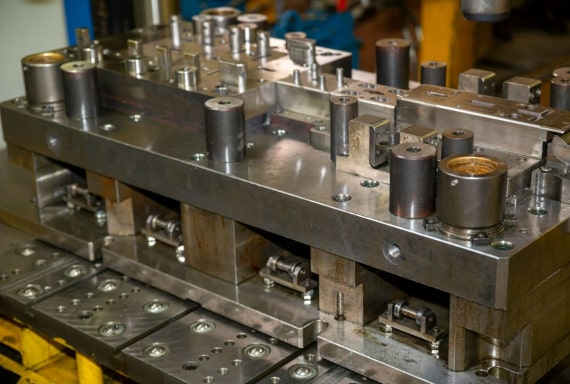

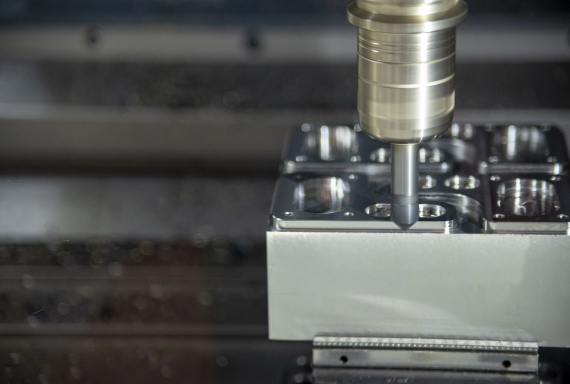

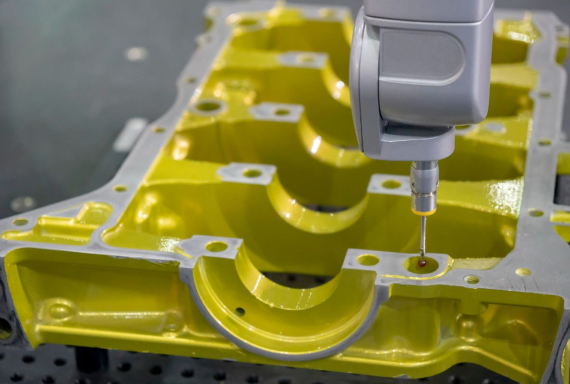

In the global plastic manufacturing industry, many resources are necessary to ensure their standards. Each of them impacts the overall production performance and the product quality. From highly advanced equipment to the best polymer materials, dedicated plastic mold makers stand out. As the experts, they are invaluable to each stage of creating and sustaining the highest quality plastic items for any application.