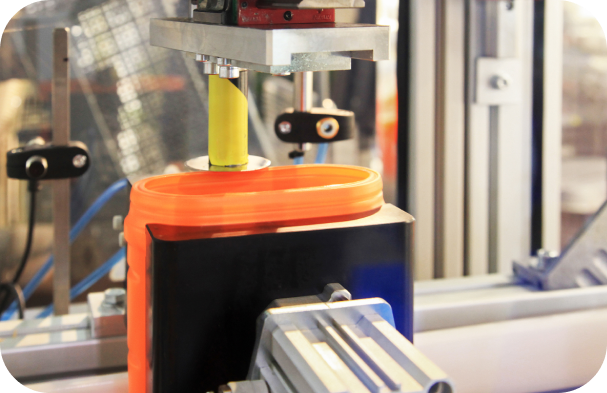

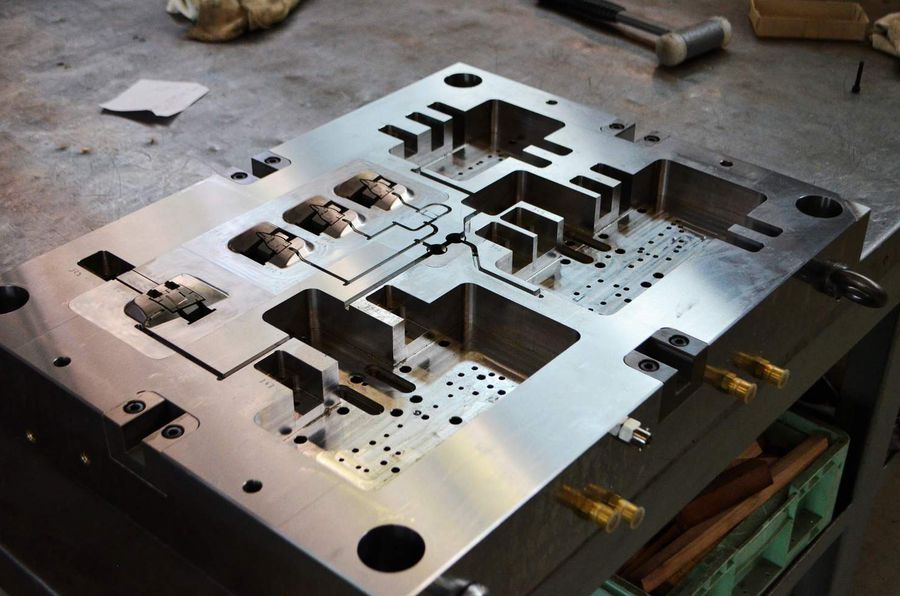

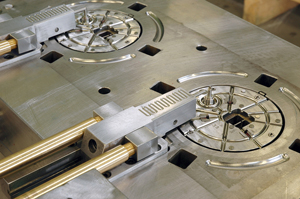

PRODUCTS AND SERVICES

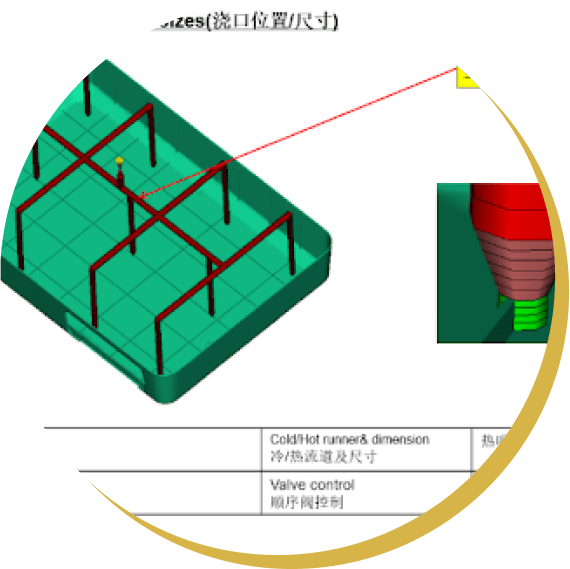

Flow Analysis Programs

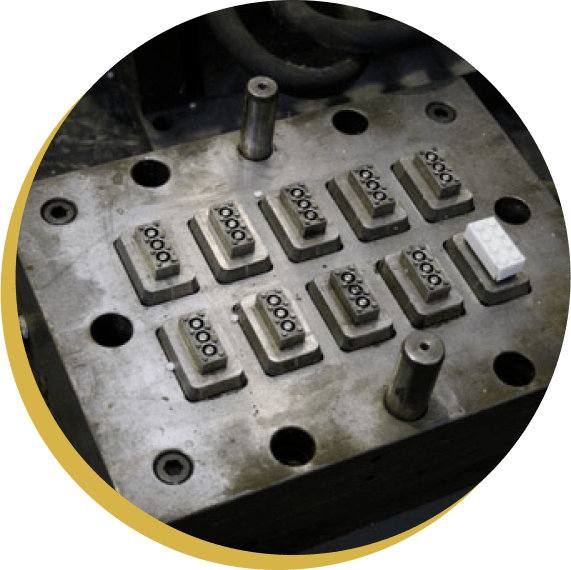

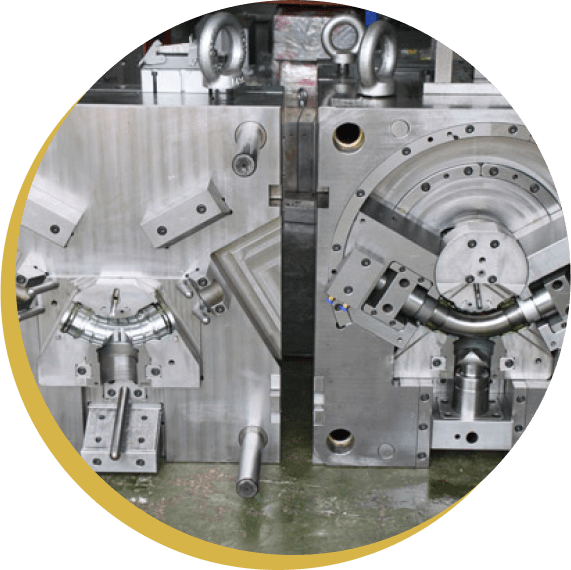

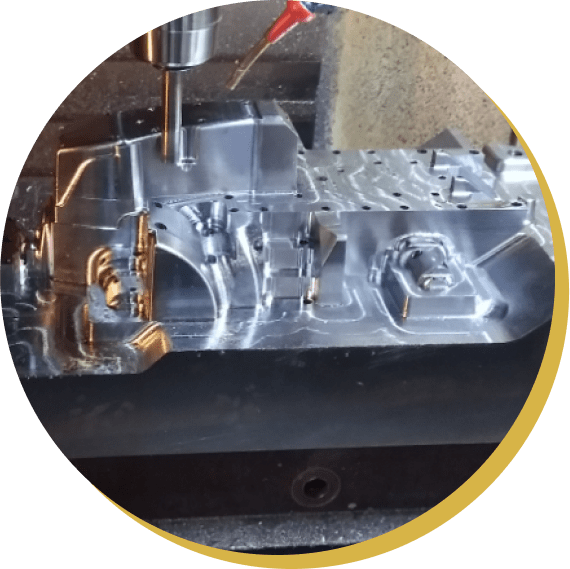

Richfields is able to utilize mold flow analysis programs to ensure that potential processing problems are highlighted at an early stage just before we start manufacturing our plastic tools and molds. If you would like mold flow analysis of your tools please inquire in advance because additional charges may apply. Our equipment, processes and years of experience make our plastic tool and mold manufacturing division a very professional, well-oriented, highly precise factory in China. Some of our strengths include: