Latest Blogs

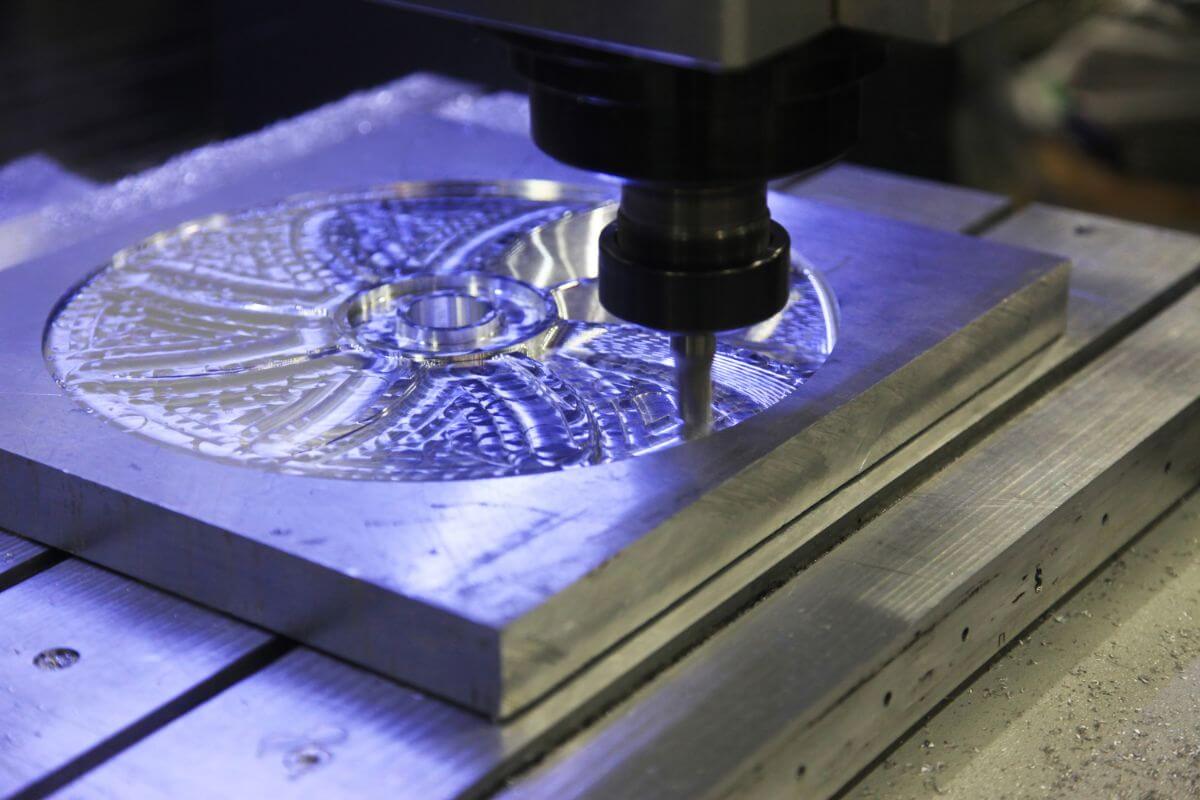

How to Ensure a Good-Quality Plastic Mold Maker

How do you ensure that you’re collaborating with a good-quality plastic mold maker? They communicate clearly They have years of industry experience They provide you with full-service support They use high-quality machines and tools They have top-notch product design skills They can produce a large volume of finished products Figuring out what factors lead to […]

Read more

Design Considerations for Plastic Overmolding

What should you consider when designing a plastic overmolded product? Understand the function of your product Consider the environmental exposure of the product Ensure the overmolded plastic adheres to the original part Maintain a uniform wall thickness Include the supporting areas on the substrate Consider the number of products you plan to produce Plastic overmolding […]

Read more

Critical Considerations For Designing High-Quality Large Injection Molded Parts

What are some critical considerations for high-quality large injection molded parts? Material Selection Mold Design Production Process Post-Production Finishing Testing and Validation Large injection molded parts are increasingly used in a wide range of industries, from automotive and aerospace to healthcare and consumer products. Designing these parts requires careful consideration of a range of factors […]

Read more

Factors that Affect the Cost of Plastic Overmolding

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read moreOther Blogs

Purging Procedures for Plastic Injection Molding Machines

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more

How Plastic Is Used As A Construction Material

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more

Plastic Use in the Logistics Industry

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more

The Use of Plastic Injection Molding in Cosmetic Packaging

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more

Advantages of Using Gas-Assisted Plastic Injection Molding

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more

What is Overmolding?

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more

Primary Applications and Uses of Polypropylene Plastic

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more

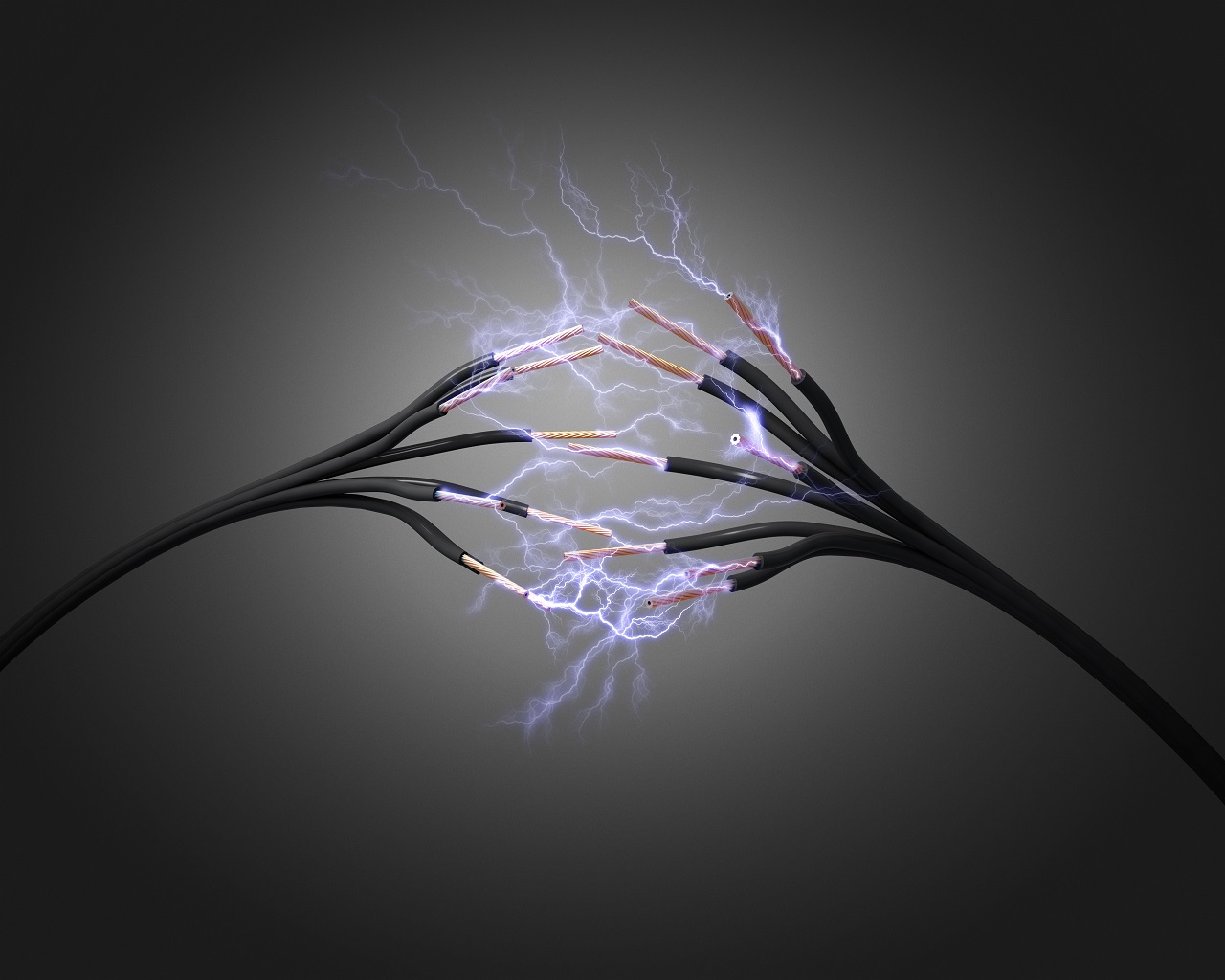

Electrically Conductive Hybrid Plastic in Injection Molding

What are the factors affecting the cost of plastic overmolding? The design of the part used The mold setup The type of material used The desired surface finish The location of the manufacturer Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some […]

Read more