Latest Blogs

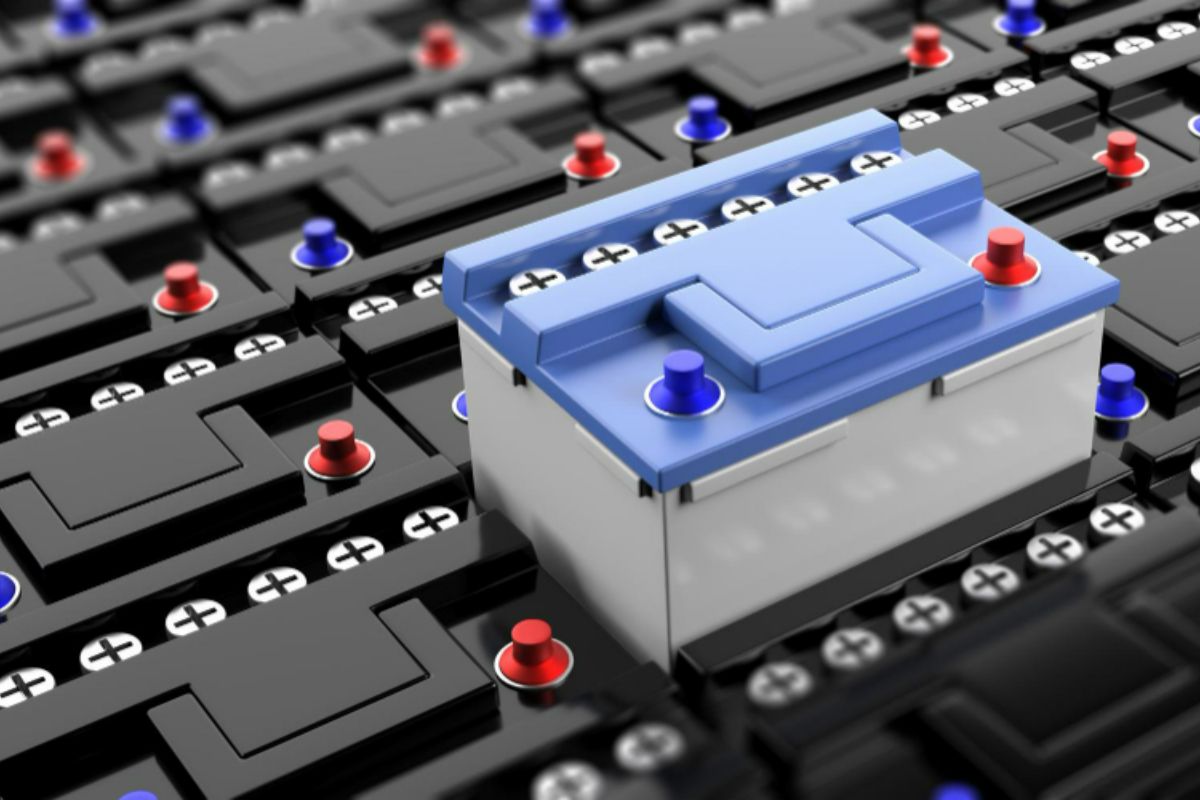

How to Choose the Right Plastic for Car Battery Molds

What are the steps in choosing plastic for car battery molds? Define battery requirements Check material compatibility Assess temperature resistance Examine mechanical properties Ensure dimensional stability Determine surface finish Evaluate overall cost Consider manufacturability Overview Understanding the significance of selecting the appropriate plastic for car battery molds is paramount to ensure both durability and efficiency. […]

Read more

What Sets High-Quality Large-Size Tooling Apart from the Rest

What distinguishes high-quality large-size tooling from other options? Material quality Heat treatment Surface finish Rigidity and stability Longevity and durability Overview In injection molding, the choice of high-quality large-size tooling is crucial for success in producing large plastic components. As industries demand precision and endurance in their plastic parts, opting for high-quality large-size tooling becomes […]

Read more

Weather-Resistant Outdoor Furniture Made Using Plastic Molding

What outdoor furniture are weather-resistant and crafted using plastic molding? Adirondack chairs Stackable chairs Loungers and chaise longues Tables Benches Rocking chairs Swings and gliders Planters Storage boxes Overview Weather-resistant outdoor furniture created through plastic molding offers a resilient, versatile, and stylish solution for outdoor spaces. With lightweight designs and easy maintenance, this furniture enhances […]

Read more

6 Key Considerations for Battery Pack Mold Making

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read moreOther Blogs

6 Reasons Why You Should Use Rapid Prototype Manufacturing

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more

5 Finish Assembly Questions to Ask Your US Injection Molding Company

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more

3D-Printed Plastic vs. Metal Tooling: Which Do I Use?

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more

6 Ways Your US Injection Molder Can Help Manage Cost

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more

8 Key Questions: Designing Injection Molded Medical Parts

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more

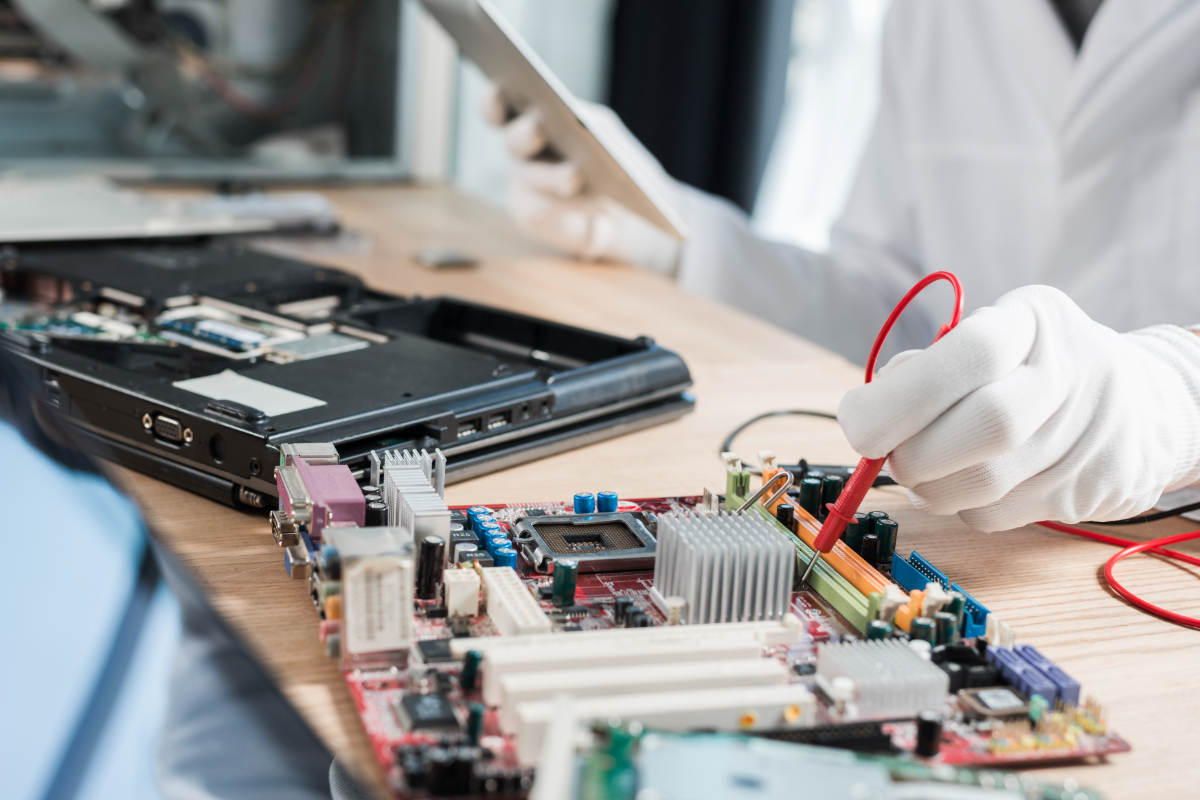

10 Common Plastics for Electronic Enclosures

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more

7 Factors of Manufacturability For Plastic Parts

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more

Thermoset Plastics vs. Thermoplastics: What’s the Difference?

What are the key considerations for battery pack mold making? Material selection Design for venting Precision and tolerance Parting line and ejection Alignment and registration Durability and wear resistance Overview Battery packs, crucial for providing portable power across diverse applications, encapsulate multiple batteries in a protective casing. Plastic injection molding, known for its versatility and […]

Read more