What benefits does using large-size tooling offer in battery manufacturing?

- Cost-efficient

- Consistency and precision

- High production output

- Enhanced design flexibility

- Improved cooling systems

- Scalability

- Competitive advantage

Overview

- The adoption of large-size tooling emerges as a revolutionary approach for reshaping the industry which is highlighted by its capacity to accommodate a larger volume of battery cells.

- Large-size tooling brings forth benefits that enhance efficiency, quality, and competitiveness in battery production.

- Richfields is positioned to satisfy the burgeoning market demands and excel in providing bespoke, high-quality battery solutions.

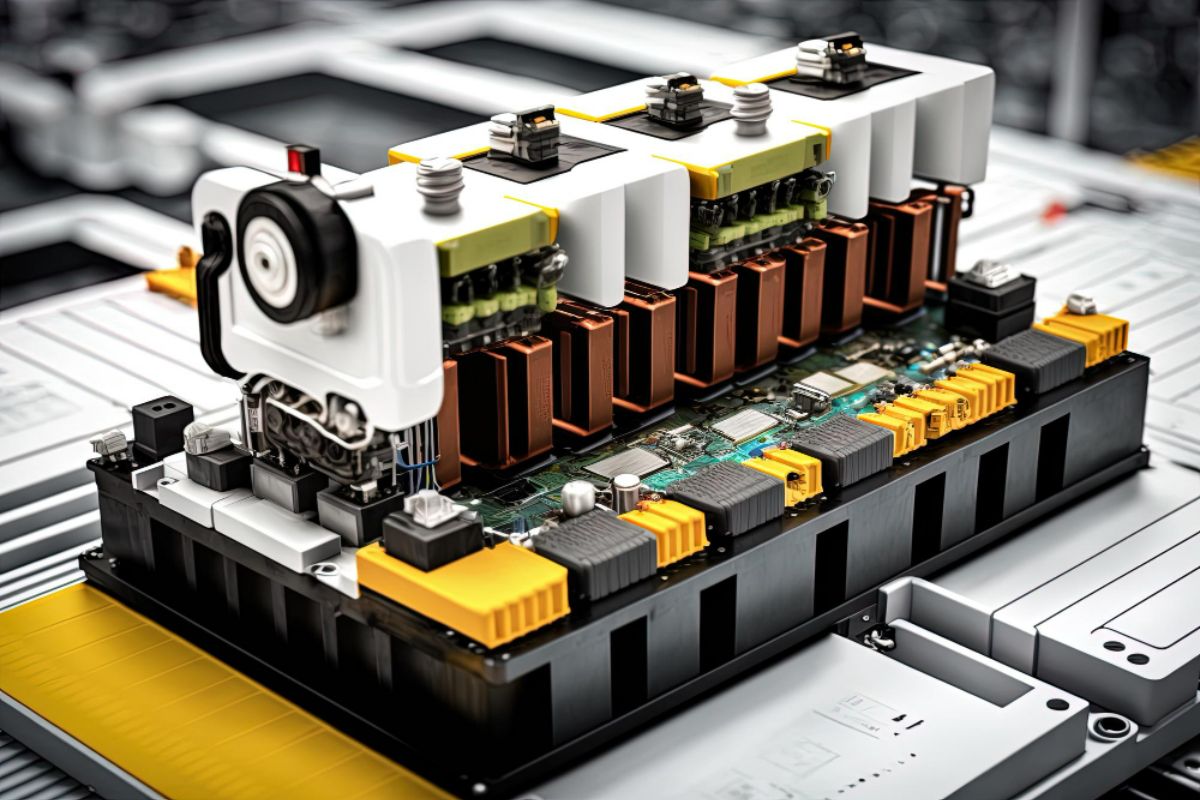

Meeting the elevated demand for energy storage solutions, the adoption of progressive manufacturing techniques has become increasingly significant. The utilization of large-size tooling stands out as a transformative method revolutionizing the industry and it was represented by its capability to adapt a greater volume of battery cells.

The advantages of large-size tooling in battery drive efficiency, quality, and competitiveness in battery production. Let’s explore its role in driving innovation and shaping the future of battery technology.

Cost-Efficient

Large-size tooling in battery production facilitates economies of scale by adopting more battery cells in each manufacturing cycle, which leads to a decrease in the cost per unit as production volume rises.

This optimization of material usage and reduction in energy consumption per unit results in significant cost savings for manufacturers over time. For instance, higher production output is achieved through large-size tooling, which enhances operational efficiency and profitability.

This streamlined production workflows allowed by large-size tooling further contribute to cost reduction by minimizing overhead costs associated with setup times and logistics. It provides manufacturers with a competitive advantage in meeting market demands while maintaining cost-effectiveness.

Consistency and Precision

To guarantee that manufacturing procedures remain uniform and accurate, large-size tooling leads to battery cells with uniform specifications throughout production. This consistency is vital for meeting the rigorous performance and safety standards demanded in battery production and significantly in sectors, such as electric vehicles and renewable energy storage.

It also enhances product reliability and durability, boosting confidence among consumers and stakeholders by minimizing deviations in battery cell characteristics. This maximizes energy efficiency and overall effectiveness. The assurance of consistent and precise manufacturing procedures provided by large-size tooling is essential for producing high-quality batteries.

High Production Output

Enabling manufacturers to accurately address the rising demand for batteries accommodates a large number of battery cells through large-size tooling. This can involve investing in new manufacturing equipment, expanding your existing facilities, or even building new facilities.

This elevated process facilitates a timely fulfillment of market demands, which supports the expanded adoption of battery technologies across different sectors.

Enhanced Design Flexibility

The production of batteries in different sizes and formats is utilized to cater to diverse customer needs. Fortunately, larger-size tooling offers greater flexibility in battery sign. This empowers manufacturers to allow battery solutions customization and drives innovation in battery technology.

It also facilitates improvement in tailored battery solutions for specified applications and industries which enhances product versatility and market competitiveness.

Improved Cooling Systems

Important in the effective management of heat generated during the production of batteries, large-size tooling enables the incorporation of cooling systems advancement.

These cooling systems do have a crucial role in securing the optimal performance and longevity of battery cells through appropriate operating temperatures. For instance, advanced cooling technology is incorporated into large-size tooling to prevent overheating and thermal degradation of battery components. The integration of these cooling systems improves the general quality and durability of batteries.

Scalability

Manufacturers are enabled to easily increase production capacity. This is in response to the growing demand for the use of large-size tooling to provide scalability.

This can be achieved by adding tooling or optimizing existing techniques that ensure long-term business growth and competitiveness in the market. Manufacturers can adapt to market fluctuations and can capitalize on growing opportunities with seamless scaling battery production capacity.

Competitive Advantage

Large-size tooling enables better quality control in battery production. By accommodating a larger number of battery cells, manufacturers can closely monitor and control the manufacturing process, ensuring consistency and accuracy in the final product.

This results in higher-quality batteries, which can give a competitive advantage in terms of performance and customer satisfaction. This helps them meet rising demand, stay competitive, and position themselves as leaders in the battery industry.

Key Takeaway

The advantages of large-size tooling in the battery are undeniable. Large-size tooling represents a cornerstone of modern battery production, which paves the way for advancements in electric mobility, renewable energy storage, and beyond.

Richfields is poised to meet the growing market demands and excel in delivering high-quality and customizable battery solutions. Our commitment to leveraging the large-size tooling and even exporting to the U.S.A. sets a precedent for excellence in battery production which empowers the company to lead in the dynamic landscape. To check our services, contact us today!