What are questions to ask for the finish assembly injection molding process?

- What quality measurement standards do they follow?

- Do they give full visibility on their internal quality control inspections?

- What capacity and experience do they have?

- How can they help with getting to the finished product?

- How much can they save you?

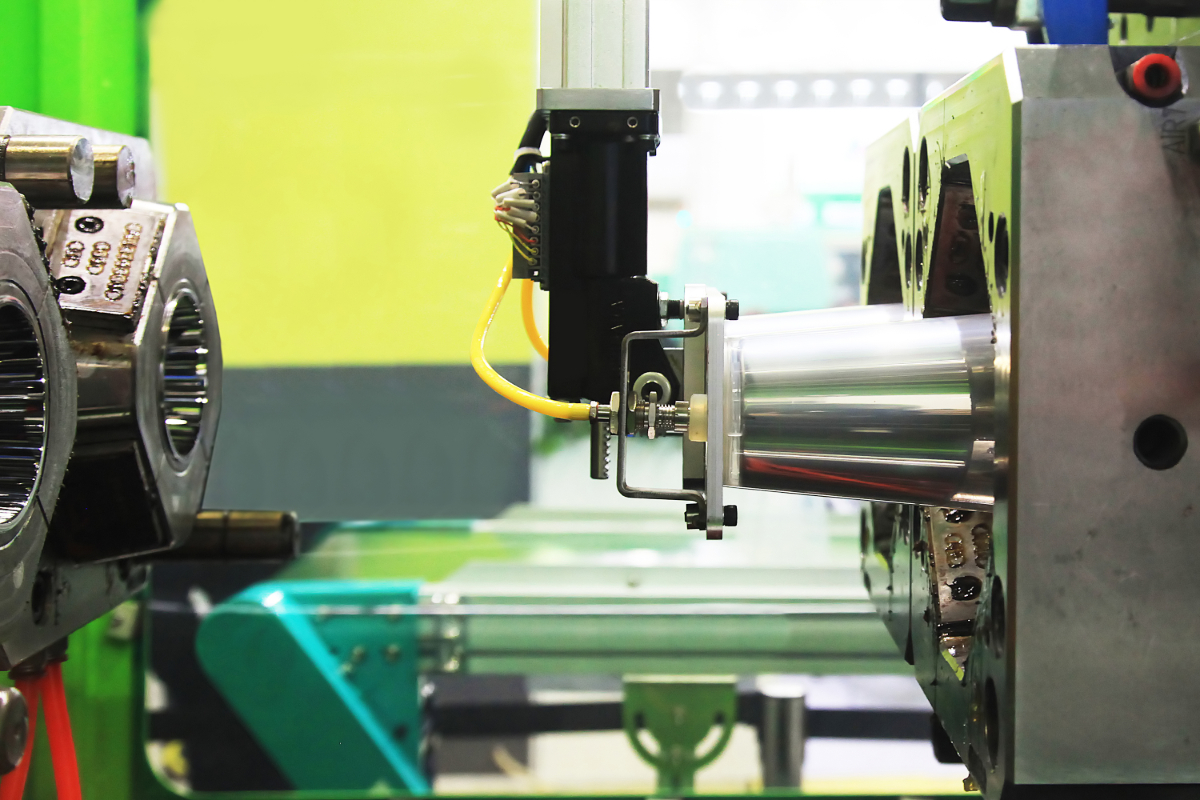

When working with an injection molding company in the US, many firms do not offer secondary and finishing services. However, when you do find one that has those capabilities and are planning on contracting them for your project, there’s a host of things to consider before a partnership. To ensure they can take care of your product, here are five important questions for injection molding finish assembly that you should ask prospective partners.

What Quality Measurement Standards Do They Follow?

Does the injection molding company you want to work with have clear-cut measurement standards? Of all the standardized quality measurement guidelines, you’ll want to work with a company that follows ISO 9001. This is because this standard requires that the company can consistently meet customer requirements when manufacturing parts.

This is also designed to prevent losses, improve compliance, and ensure proper measurement and monitoring of your products. Ask if the US injection molding company you plan on working with is ISO 9001 certified.

Do They Give Full Visibility On Their Internal Quality Control Inspections?

It’s not enough that the molding firm tells you about their quality measures. They also have to assure you that you will be receiving full disclosure on their quality control inspections and their findings. While this might seem like a given to some, other injection molding companies come with a heavy dose of opacity and poor communication.

The reason that full visibility is so important is that if you see something you are unhappy with regarding your product, you will still have enough time to discuss and rectify that issue with your injection molder. Otherwise, you might proceed with shipment, payment, and receive an unsatisfactory final product.

So how do you know you’ll stay in the loop? The simplest way is to ask for more details on their quality control process. Ask when they do formal inspections, how those are documented, and how findings are communicated to you. Will they show you a failed report? Can corrective action reports be shared with you?

What Capacity And Experience Do They Have?

When you take on an injection molding service to create your initial and final product, you will want to work with a team with specific qualities and experience.

Consider their project portfolios, reviews, and equipment — try to see if this injection molding company specializes in the product you’re making, or has experience with similar products. It’s a plus if the company has a wide breadth of knowledge, as this ensures your manufacturing partner will know how to adjust quickly to your parts.

Aside from their expertise, their capacity is also very important. Especially for larger production runs, you want to be sure that your injection molding partner can handle the amount of work you need to be done.

They should have no issues storing, working on, and shipping parts. Their company should also have enough space and organizational skills to manage high volume demands without leaving parts outside or scattered about.

How Can They Help With Getting To The Finished Product?

No two product developments will be alike. This is why this question is important to ask, even more so when your product is fairly complicated, or requires several secondary services. Checking if they know the right development, pre-production phases, secondary services, and finishing touches your product needs is the only way you’ll know production can go smoothly.

Some US injection molding companies have experience with a variety of tasks that can help your project move along to its final stages. Other relevant questions to ask regarding this include the following:

- How many people will be contracted to work on my project?

- What kinds of final assembly work do you do?

- Do certain components of my product need to be sourced?

- Will finishing be in-house or outsourced to another location?

- Do you possess the necessary tools, or are there special tools that will need manufacturing?

- Will you offer shipping services?

How Much Can They Save You?

One of the primary reasons you rely on US injection molding companies to fabricate your products is to cut back on costs. Working with one company at all stages is an incredible cost saver, as it adds savings when it comes to logistics, sourcing, service fees, and more.

Ensuring you’re working with the right partner also helps cut back on potential losses. If the team working on your product from its initial molding to finishing is skilled and attentive, then they will become intimately familiar with its design and parts.

So, make sure to ask about the team that will be in charge of your project, and if they have experience with finishing assembly. If defects should happen, you will want a group that’s familiar with what needs to be done, helping you save time and money.

Key Takeaway

Finding a good company and asking the right questions for finish assembly for injection molding is key to ensuring your product’s manufacturing goes as smoothly as possible.

Here at Richfields, we are ISO certified, we train our people to maintain high manufacturing standards, and we work closely with our clients to ensure the highest satisfaction with our development and manufacturing process.

Unsure of where to get started on your product development? Contact Richfields today and get in touch with our injection molding experts. We can provide consultation and assist you with getting your product through design, development, manufacturing, and more.