Why should you use rapid prototype manufacturing?

- Makes ideas and discussions concrete

- Reduces product development costs

- Provides functionality testing

- Reduces risk of product failure

- Improves client and stakeholder involvement

- Evaluates human factors and ergonomics

When it comes to developing your product, nothing is more important than the prototyping stage. This is critical in testing different components, refining your product ideas, and providing a viable path to your final product.

In making injection molded products, rapid prototyping is a service that provides all of these benefits, allowing you to allocate your time and resources effectively. In this article, we break down why you should use rapid prototype manufacturing, and how this decision affects your product development cycle in the long run.

What is Rapid Prototyping?

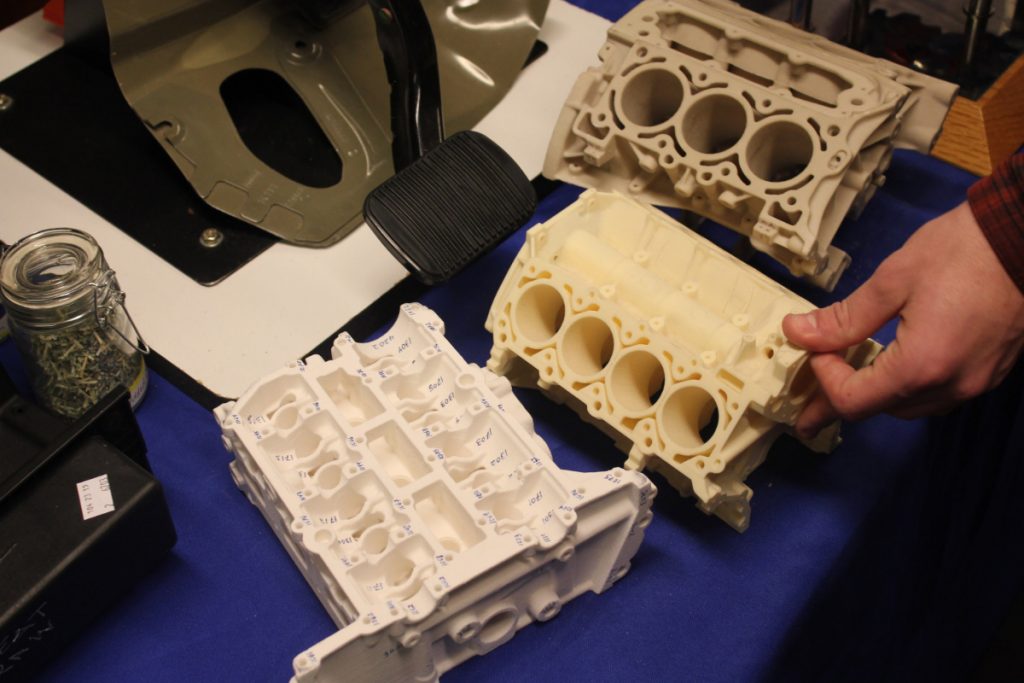

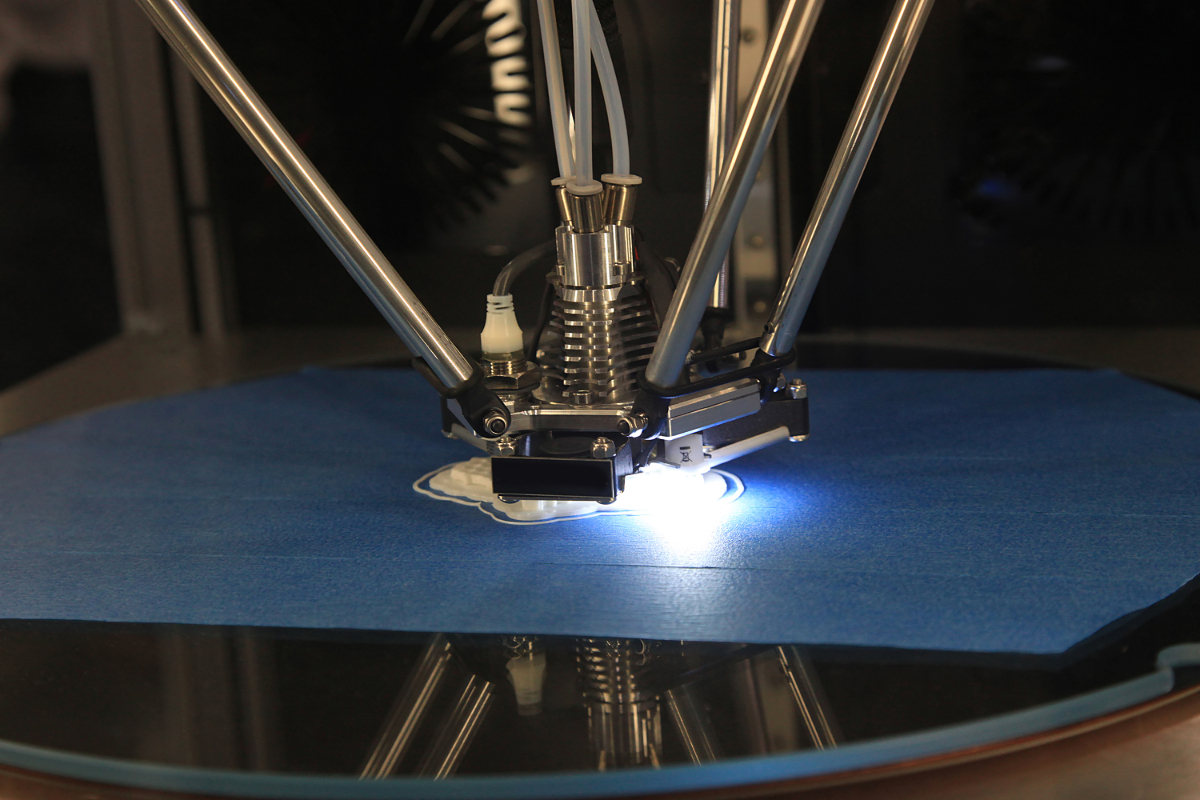

Rapid prototype manufacturing is a process that is used to quickly and continuously create prototypes of your product. This is usually done with the use of computer-aided design technology (CAD) and injection molding equipment. These prototypes are used to test and validate versions of your product during development.

Rapid prototyping allows for multiple variations of a prototype to be created in a drastically reduced amount of time when compared to traditional prototyping methods. This is the fastest way to seamlessly integrate the testing and development phases of your product.

Makes Ideas and Decisions Concrete

Oftentimes, it’s difficult to discuss your product with stakeholders, developers, and members of your team when all you have is an idea. It can be confusing for some to envision the product you have in mind. With rapid prototyping services, you can save time when presenting your ideas because everyone can now see and discuss the next product.

Furthermore, by having a physical product, people will better understand its intended purpose and your vision. This is especially valuable when you’re pitching your design to investors or other external stakeholders.

Rapid prototyping is also useful in testing and validating ideas. With the use of this service, you can hold focus group tests, show them a rapid prototype, and receive their inputs and impressions. Co-workers, clients, and distributors can also be asked how they feel towards the product and whether they like the design or experience of it.

Reduces Product Development Costs

Although this is an important stage in production, prototyping is usually considered a bottleneck. Most of your time may be spent trying to come up with a viable and attractive product design. This can be tedious and can result in wasted time, effort, and materials.

This is where rapid prototyping shines. It significantly reduces the time taken during the redesigning phase of the production process, as creating prototypes to test takes much less time. With rapid prototyping, less resources are needed to design your product perfectly and have it market-ready.

Provides Functionality Testing

A rapid prototype will reflect exactly how your product will be made based on your current designs. Having one is a great way to do some functionality tests, and check how your designs feel, look, and operate in reality. Testing and retesting your product in its current design provides you the opportunity to finetune your ideas (if possible) and redesign them into a winning product that’s more likely to succeed on the market.

Receiving prototypes as quickly as possible and in multiple variations helps you determine if they offer a good user experience and if they operate in stellar condition. At this point, you can uncover features and components that need more work, or where their capabilities can be expanded further.

Reduces Risk of Product Failure

Creating rapid prototypes gets your developing product to your designers much faster. This way, they can discover major issues while early on in the testing phase. These flaws can be disastrous if your product is mass-produced and sent to the market with them.

It’s much better to have these problems fixed multiple times at your facilities than to try and fix a finished product that’s already with the end customer. A thorough evaluation of your design using working prototypes greatly reduces the risk of product failure in the long run.

Improves Client and Stakeholder Involvement

Getting prototypes into your hands as quickly as possible also opens up the opportunity to collaborate with your stakeholders. By providing them with a prototype they can test themselves, you can ask for constructive feedback from such vital sources.

It’s recommended to first create and test a prototype that meets your expectations, and then present that version for your clients or stakeholders to explore the product for themselves. Using an enhanced prototype model ensures that the feedback you receive from them will be close to the feedback you’ll receive for your final product. This improved involvement can also reassure stakeholders in their investments toward your ideas.

Evaluates Human Factors and Ergonomics

Product designers and engineers need to identify human factors, ergonomics, and other safety issues with your desired product. Rapid prototyping helps them get to the root of any possible risks involved with your product design.

Designers can even test different hypothetical designs at the same time. Numerous components, materials, and features can be added or changed during this process, making it easier for them to find the ideal combination of all three. As a result, they can hasten the prototyping process and move closer to your final product sooner than anticipated.

Key Takeaway

There are many reasons why you should use rapid prototyping manufacturing. With its numerous benefits, you can streamline your design process, speed up production, and get a perfect final product to the market at the most opportune time.

If you’re looking for a rapid prototyping business in the US or other similar custom design solutions for injection-molded products, contact Richfields today! We specialize in providing high-quality and express services for precision plastic products and molds. Learn more about our capabilities here, or send us a message here!