What are the benefits of using recycled plastics for injection molding?

- Environmental sustainability

- Less expensive than virgin plastics

- Reduced energy consumption

- Reduced waste

- Can make new and unique plastic products

Overview

- Recycling plastics for injection molding provides an environmentally sustainable solution with cost-saving advantages.

- By using recycled plastics, it reduces energy consumption and minimizes waste generation.

- The versatility of recycled plastics allows for the creation of innovative and unique products that meet market demands and support sustainability efforts.

Recycled plastics, commonly known as plastic resins, are substances obtained by recovering and treating plastic waste from either consumer or industrial sources. The utilization of these plastics for injection molding is a compelling solution with far-reaching advantages. This method not only contributes to environmental conservation but also proves economically beneficial.

Through this article, we’ll explore the extensive benefits of recycled plastics for injection molding. From reducing waste to enhancing resource efficiency, product quality, and more.

Environmental Sustainability

Incorporating sustainability into manufacturing by using recycled plastics is essential for our environment. By reducing the demand for new plastic production, we conserve natural resources and reduce energy-intensive manufacturing processes.

For example, recycled polyethylene from used shopping bags can be effectively used in crafting storage containers, decreasing the need for new polyethylene production and reducing the carbon footprint. On the other hand, recycled polyvinyl chloride sourced from old pipes and fittings finds application in various products like flooring, cable insulation, and automotive parts.

This not only minimizes environmental harm but also promotes responsible waste management by turning these wastes into valuable resources.

Less Expensive than Virgin Plastics

These recycled resins offer businesses an advantage. This is due to the cost-effectiveness of these recycles compared to virgin materials. Opting for these can lead to substantial reductions in material procurement expenses, making the injection molding process more cost-efficient.

Take recycled high-density polyethylene from used plastic bottles, for instance. It’s both eco-friendly and budget-friendly for injection molding. Using these recycled materials cuts production costs while supporting sustainability.

Embracing these plastics allows you to save money while contributing to sustainable practices, making injection molding a financially prudent and responsible choice.

Reduced Energy Consumption

The production of virgin plastics involves resource-intensive processes, such as drilling for oil or natural gas, refining these raw materials, and then converting them into plastic polymers. These processes require heavy energy inputs, which can be reduced when recycling plastics.

Recycling involves the collection, sorting, cleaning, and processing of used plastic materials. While it still requires energy, these steps generally consume less energy than the extraction and processing of raw materials for virgin plastics.

As a result, manufacturing products through injection molding with recycled plastics becomes more energy-efficient. This translates into less energy usage, reducing the overall carbon footprint of the process.

Reduced Waste

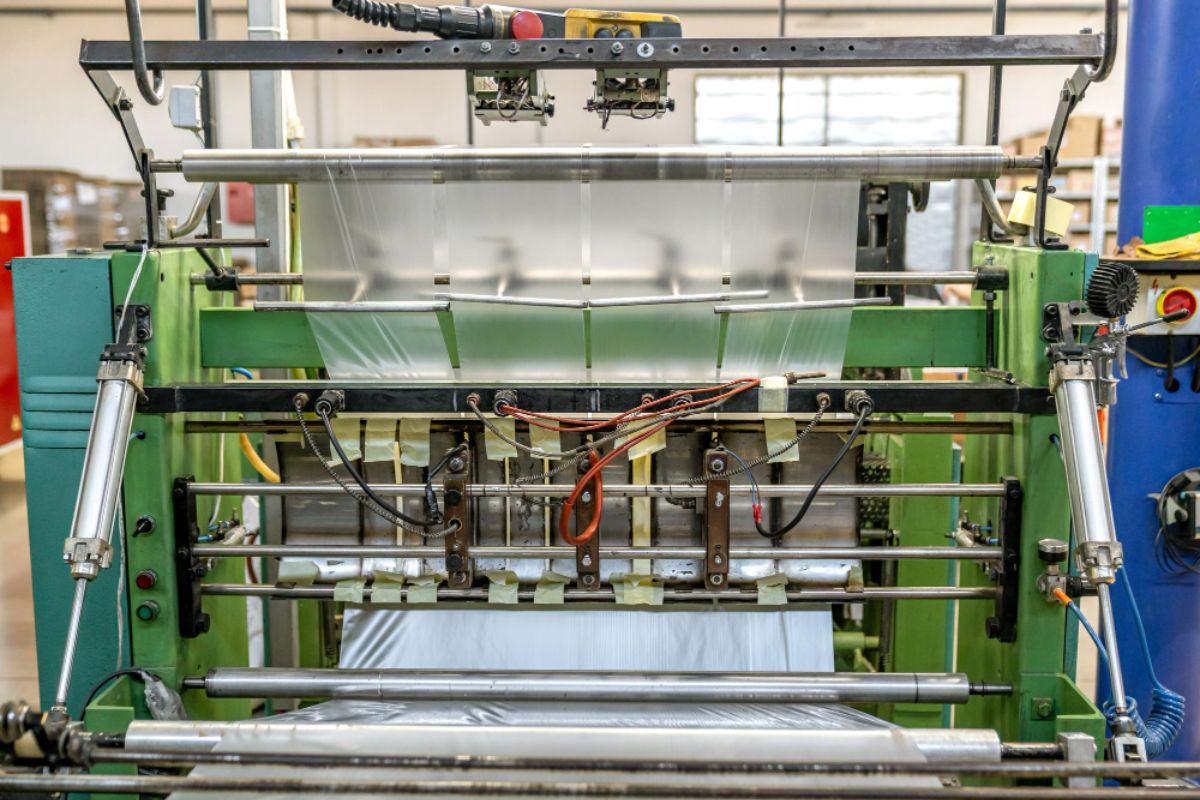

These plastics are highly effective in reducing waste across various stages of its lifecycle. They are repurposed as raw materials for new products, which is especially evident in injection molding applications, such as tools, devices, cases, toys, door panels, and more.

Even at the end of their product life, these recycled resins continue to contribute to waste reduction. Many of these products can be used once again, creating a closed-loop recycling system. This further curtails waste generation and promotes a circular approach to plastic use.

By incorporating these plastics, you ensure that they stay within the recycling stream and out of natural ecosystems, addressing this crucial environmental concern.

Can Make New and Unique Plastic Products

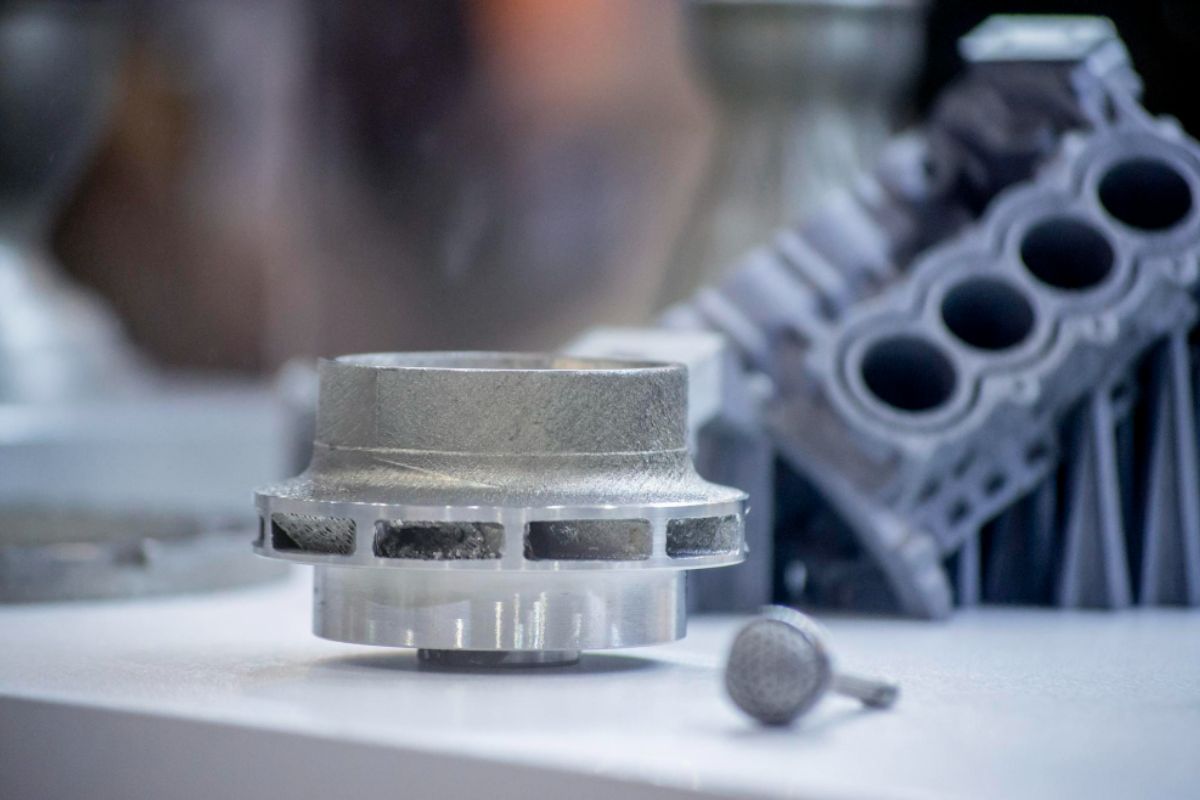

Recycled plastics offer a wealth of opportunities for the creation of new and unique products. Their inherent versatility makes them a valuable resource for innovative product design.

For instance, you can blend different types of used plastics, and hybrid materials with unique properties can be crafted. The combination of recycled polyethylene and recycled polypropylene can result in a material that strikes a balance between strength and flexibility, making it suitable for a wide range of applications, such as automotive components, consumer goods, packaging materials, construction materials, furniture, and more.

Their excellent characteristics, such as increased strength, reduced weight, and improved insulation make these composites commonly employed in various industries.

With creativity, innovation, and a keen understanding of material properties, manufacturers can harness recycled plastics to develop products that not only meet market demands but also contribute to sustainability endeavors.

Key Takeaway

We’ve just featured the benefits of recycled plastics for injection molding. This contributes to environmental conservation by reducing the demand for virgin plastic production, lowering production costs, and presenting a step towards sustainable, financially, and economically viable manufacturing practices that all industries should follow.

Richfield Corporation specializes in producing precision plastic products, ensuring timely and secure delivery to your location. We are committed to providing first-rate plastic solutions that cater to various industries’ specific requirements. For any inquiries or more information, don’t hesitate to contact us here.