What are the benefits of using a US overmolding supplier?

- Enhanced product performance

- More customization capabilities

- Increased product appeal

- Lowered production costs

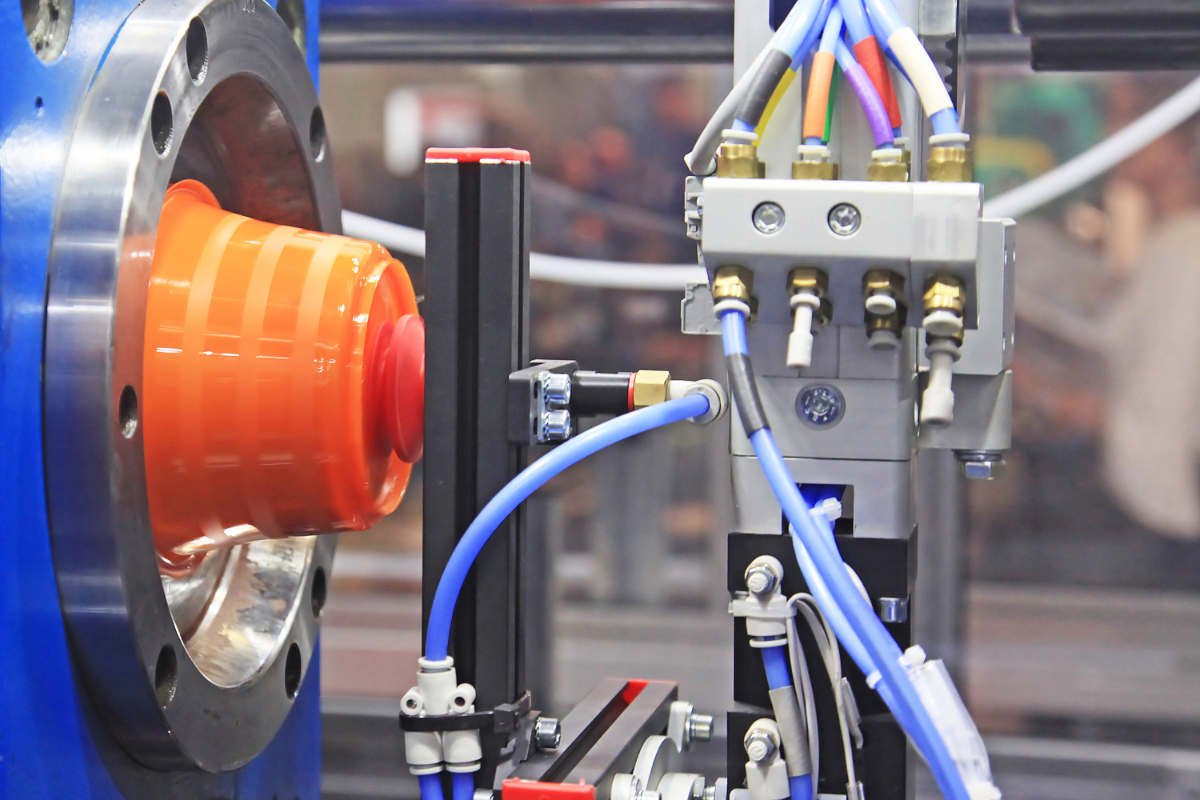

Rubbers and plastics make many of the products and tools that all industries use daily, possible. To make these products and tools, manufacturers often use a process called overmolding, which is used to combine two plastic or rubber materials together.

Through overmolding, you can enhance your products both aesthetically and functionally at significantly less cost and effort, which is why there are many benefits of using a US overmolding supplier. In this article, we cover how overmolding creates advantages for you and your product.

Enhanced Product Performance

A primary service that overmolding suppliers in the US provide is that they design and manufacture a product to improve its performance. These enhancements are possible through the beneficial process of overmolding.

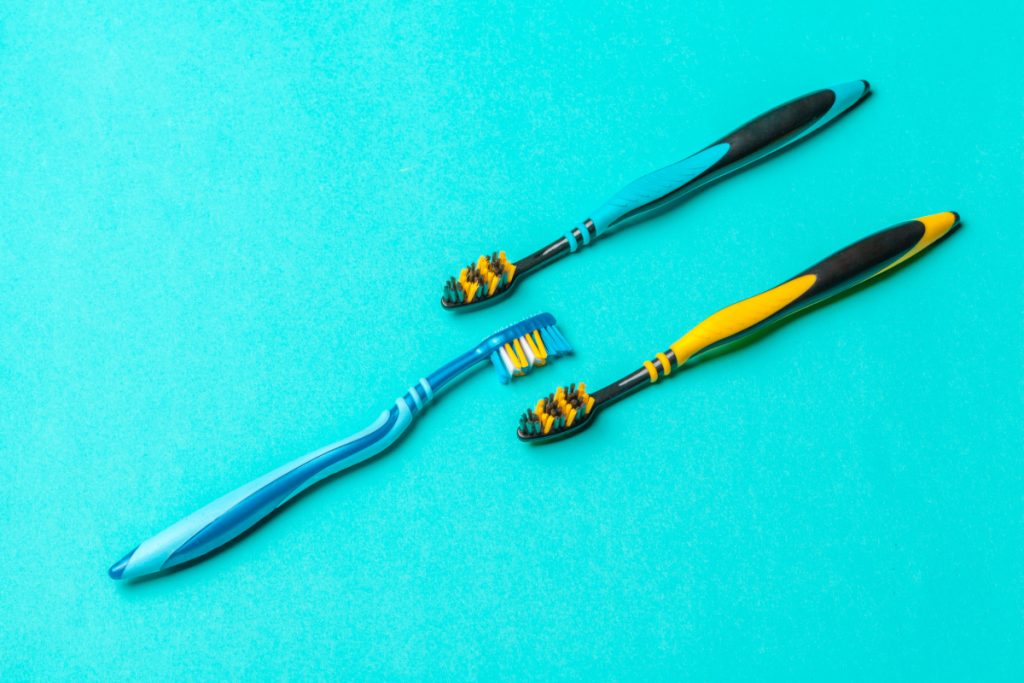

For example, overmolding allows suppliers to use Thermoplastic elastomers (TPEs), which are a diverse family of rubber-like materials perfect for creating non-slip and soft grips on products. This provides tactical sensitivity and comfortable grip, which is crucial for specialized tools like surgical instruments.

Overmolding can create ideal combinations of plastic and rubber to fulfill the following qualities:

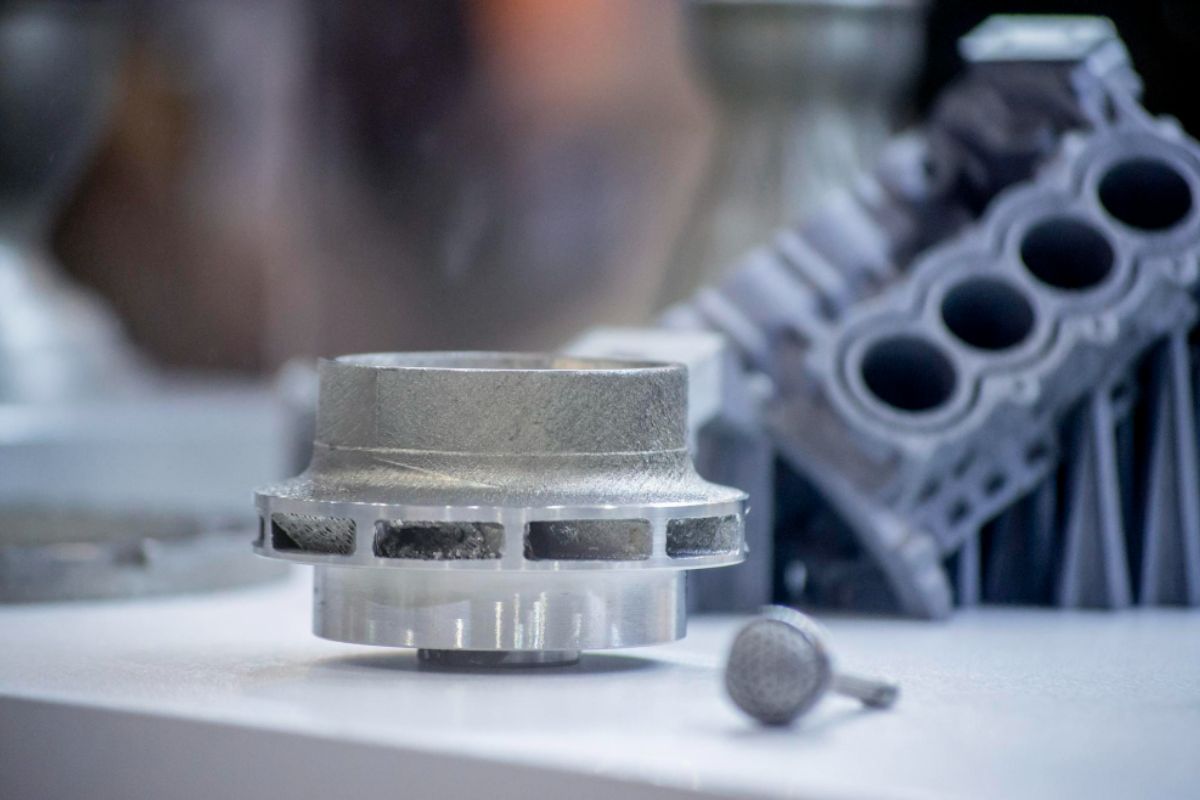

Durable Designs

There are other ways to create more durable products in injection molding and fabrication, but when it comes to fusing different materials, nothing beats overmolding.

Suppliers can combine materials without the risk of debris, vibrations, and other sources of wear and tear that would eventually break the materials apart. Overmolding suppliers ensure that the materials are permanently bonded together, and can withstand stress and other forms of friction without weakening.

Vibration Values

Overmolding also allows suppliers to isolate materials that are more susceptible to vibration and associated damage. After isolation, they can cushion them, which protects them from wear and tear over time. This eliminates possible sources of friction, damage, and reduces the amount of sound or vibration that the product itself makes.

Safety Solutions

Plastic product manufacturers can make more complex shapes and figures without sacrificing safety. Overmolding allows parts to be molded with different polymers, elastomers, and rubbers over sharp corners or edges, which reduces the risk of injury for the end-user.

More Customization Capabilities

Another advantage that overmolding suppliers have is the level of customization they can apply to your finished product. While it is possible to overmold existing products, it is best to apply this process from the start to perfectly meet the customization requirements of your application.

Suppliers can add the following components to your final design:

- Specialized overmold color, which can be used to color-code assemblies, complement brand colors, or matches with accessories or accompanying equipment.

- A stamp, logo, company name, or emblem on the product’s surface.

- Flanges, which can be used at the product’s attachment points.

- Complex sides, available in straight, right-angle, or any other form required to meet the needs of your application.

- LED indicator lights, which are used to indicate issues with your assembly. This decreases repair time and increases the safety of use.

- Specialty materials, such as thermoplastic polyurethane (TPU), polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE), or acrylonitrile butadiene styrene (ABS).

Increased Product Appeal

Overmolding suppliers can help your product stand out amongst other competing products. This is because the materials used and made through this process can create a more visually appealing surface or appearance. They also come in a wide range of colors and can be further engineered in various finishes. This versatility can be used to create different effects, such as:

Aesthetic Advantages

Suppliers provide greater flexibility to clients and designers who want to add unique aesthetic elements or designs to their products. Overmolding allows you to use any combination of materials, colors, and additions on your final product.

Ergonomic Enhancements

Besides adding beauty and style to a product, overmolding has practical benefits. Suppliers can use this process to create a more ergonomic design through the shape, thickness of the product. Overmolding can also be used to make certain materials easier to grip, and more comfortable to handle.

Lowered Production Costs

Overmolding is rare in that it adds value to the product, yet also allows suppliers to cut back on production costs. This is possible through the overmolding process itself. It condenses the number of manufacturing steps needed to create a final product.

Without the need for secondary finishing or the individual molding of product components, you need less manpower, machine, and materials overall.

Is Overmolding Right for Your Project?

Overmolding can be used in several applications, but the following factors must be considered before choosing this process over other injection molding solutions:

- Product design

- Materials selection

- Tooling quotes and equipment budget

- Labor costs

- Production volume

Overmolding is ideal for products that need to be as aesthetically pleasing as they are reliable. The most common applications that overmolding suppliers are experienced in include fabricating medical equipment, consumer electronics, and OEM applications.

Key Takeaway

The significant benefits of using a US overmolding supplier come from its advantages in product design and production costs. But while this may be a potent method for creating your product, partnering with an experienced fabricator and supplier — especially one with injection molding expertise, like Richfields — is needed to receive these benefits.

With an industry leader, you’re guaranteed the expert incorporation of this process in your design and manufacturing phase. Send us a message here to learn more about how our services work, and what we can do for you.