What are the components of hot runner molding systems?

- Nozzle Body

- Manifolds

- Inlet

- Heater Technology

Overview

- The hot runner molding system is essential for high-quality, large-volume production across various industries.

- The nozzle body, or drop, connects to the mold cavity, delivering the molten plastic.

- Manifolds evenly distribute molten plastic to different nozzles and injection points.

- The inlet controls the flow of resin from the nozzle to the cavity.

- Heater technology in hot runner molding systems maintains the necessary high temperatures, ensuring precise and reliable plastic part production.

Hot runner molding systems are integral to the plastic injection industry, offering benefits to various items. However, to understand its revolutionary nature, we must first understand the basics of the method.

In this article, we explore the components of hot runner molding systems. Each part is a necessity and impacts the quality of the items. Read on to learn more.

What is a Hot Runner Molding System?

China has been one of the leading plastic manufacturers in the world. In 2019 alone, it exported over 14 million metric tons of plastic products. The two provinces with the most production are Zheijang and Guangdong, producing 12.8 and 12.75 million metric tons respectively. With this much volume in their production, it is only necessary that they use the best methods and machinery.

Among the many plastic production equipment, the hot runner molding system is highlighted to be one of the best. It is a reliable tool for making high-quality plastic parts for any product. It uses high temperatures to work. As a process, it delivers a volume of mold plastic to mold cavities.

The hot runner molding system has many advantages. The system allows for increased productivity. It can even produce in large volumes, meeting demands without compromising quality. It is an engineering innovation, allowing you to mold precisely no matter the complexity of the design.

You can see the common products made by this method through the following items:

- Bottles and caps

- Syringes and inhalers

- Housings for phones and laptops

- Interior automobile trim panels, fenders, and bumpers

- Buckets and storage containers

This type of plastic injection process encompasses many industries. These include medical, automotive, consumer, military, and aerospace sectors. As one of the most versatile techniques in plastic manufacturing, it is a trusted process for creating different and excellent products for you.

Components of Hot Runner Molding Systems

Hot runner molding systems offer numerous benefits in manufacturing plastic. Every component works seamlessly to optimize production. Each is only a result of having high-quality parts.

Nozzle Body

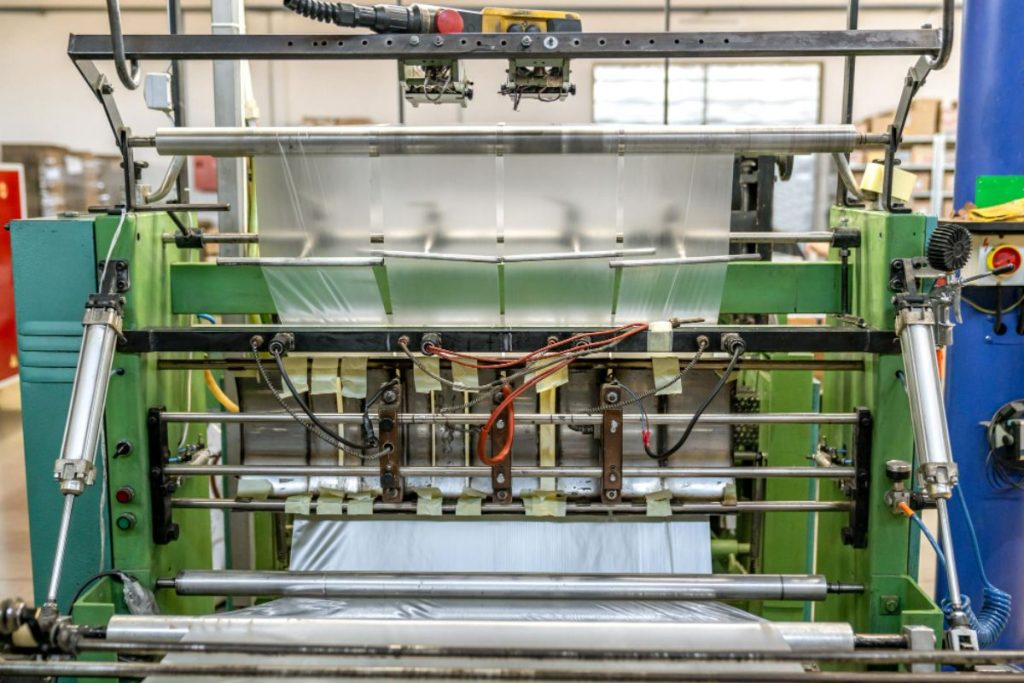

The nozzle body, also known as the drop, is the component that links to the cavity. The cavity is the mold itself. Carved into it is the intricate design of the product part. If it is not directly gated into the molding, it may lead to the sub runner that will open to the cavity.

It delivers the molten plastic into the mold cavities. It is designed to withstand and maintain high temperatures. This will prevent plastic from solidifying too quickly. There are four style categories available for this part. These are the threaded, support ring, single-valve gate, and sprue bushings nozzles.

Manifolds

Before the liquid plastic reaches the nozzle, it first goes through the manifolds. This part enables the flow of the molten material into different nozzles and injection points.

Like the molding cavity itself, manifolds have their own distinct designs and shapes. Their uniqueness to your process is what results in an improved molding process. This allows you to create quality design plastic parts.

Their purpose of evenly distributing liquid plastic is what makes the hot runner molding system cost-effective. By controlling the flow of volume, it ensures that there is minimal waste of molten plastic

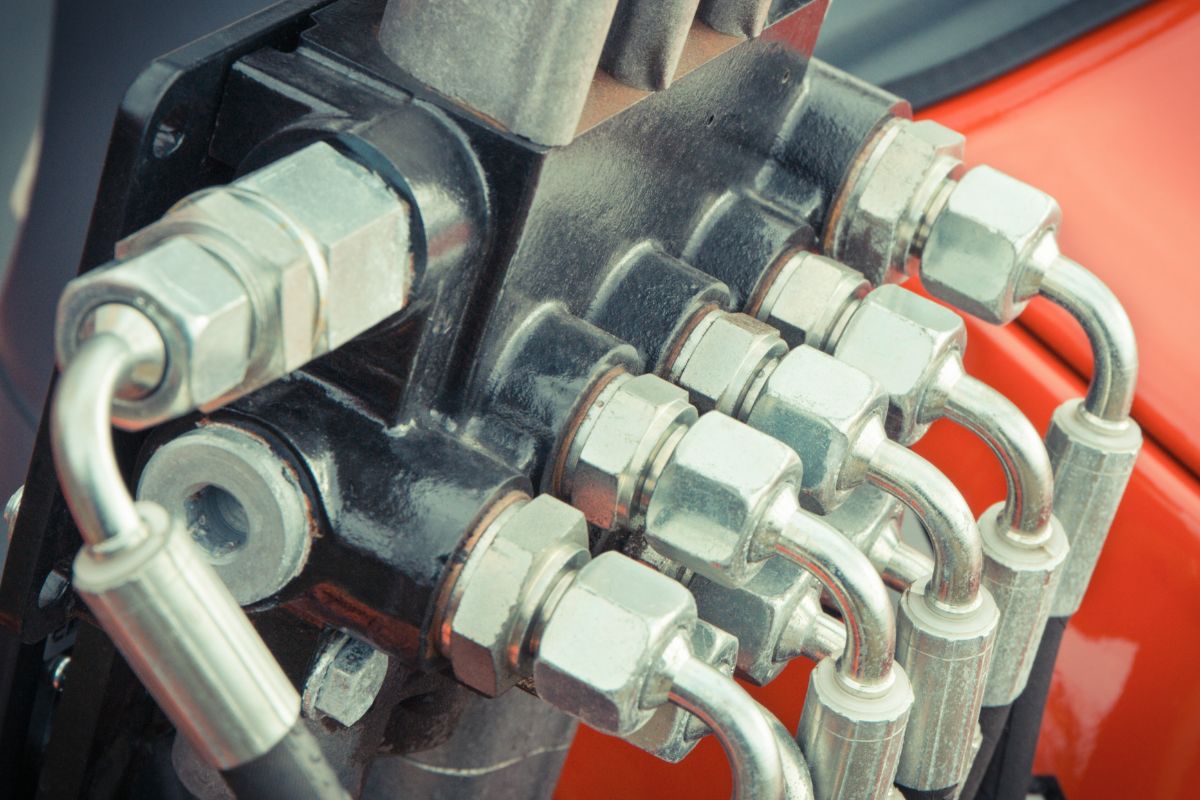

Inlet

The inlet is the entry point of the resin into the mold. In other words, it is the gateway from the nozzle to the cavity. It serves the hot runner molding system in many ways. One of which is controlling the flow of molten plastic. It also comes in many designs and shapes to control how much volume enters the mold.

Depending on the type of plastic resin, the inlet may be heated to ensure a smooth transition from nozzle to mold. This prevents the premature solidification of the liquid material.

Heater Technology

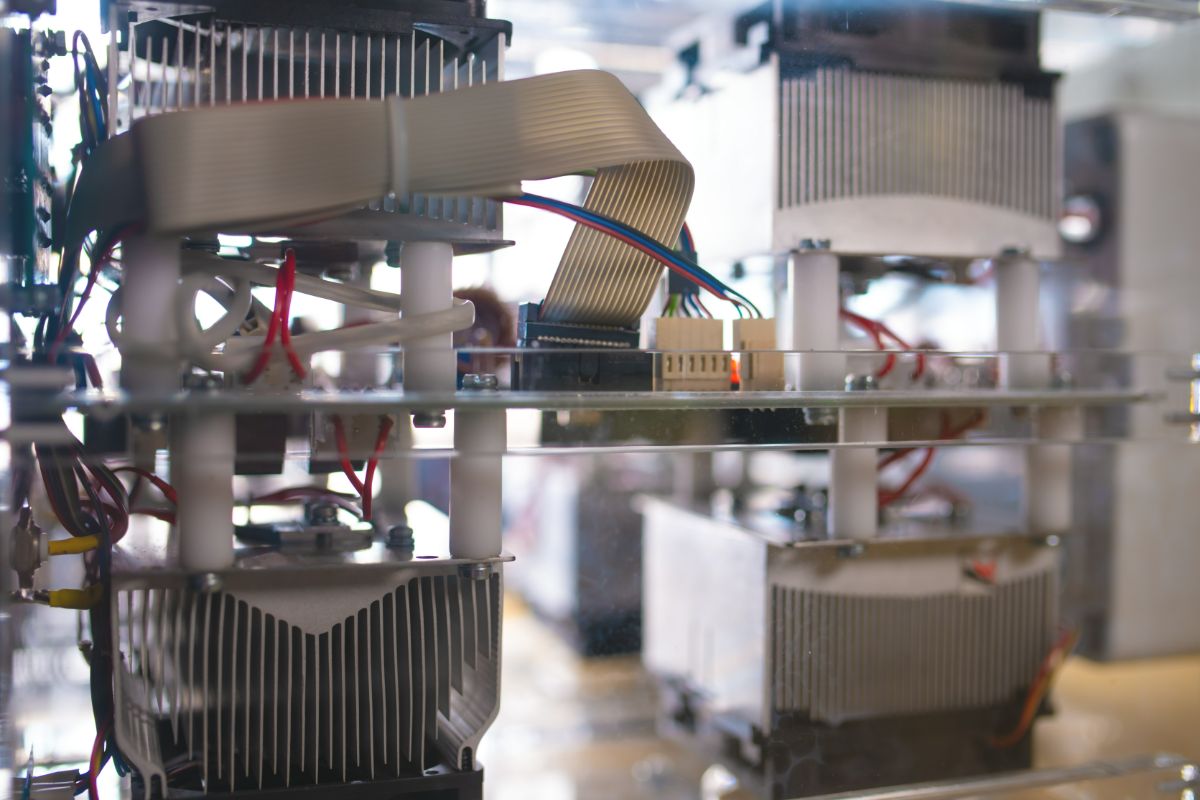

The hot runner molding systems work in high-temperature settings. It is the basic foundation of the tool. When the process is done in hot temperatures, it ensures that each plastic part is produced accurately. That is why the heater technology in the machinery is important.

However, this technology depends on an array of factors since it can come from different parts such as heater bands or plates, paste-in or flex heaters, or brazed-in heaters.

Key Takeaway

The components of hot runner molding systems are important in manufacturing plastic. Learning about these is essential for the reliability of this technique. After all, to ensure the standards of your products, it is necessary to learn how to regularly maintain the equipment of the process.

At Richfields Corporation, we ensure our hot runner molding systems are maintained well for every use. It is not only with this equipment but also with the other tools we use in creating your ideal plastic product. As your trusted plastic molders, we make sure that we give you the best machines to ensure the highest quality. So, to start making your hot molded plastic items, do not hesitate to contact us today and inquire.