What are the advantages of conductive hybrid plastic?

- High conductivity and temperature tolerance

- Lightweight structure

- Cost-effective

- Easy to produce

Plastic is well-known in manufacturing as a light, affordable, and versatile material used in various products and applications. As the demand for high-quality plastic remains across the world, mold making in China and the United States has become a thriving industry. Along with being an in-demand material, plastic has also continued to bring in modern innovations as well. One of these is the introduction of electrically conductive hybrid plastic, which has become a material with immense potential to improve today’s technology.

What is Electrically Conductive Hybrid Plastic?

Electrically conductive hybrid plastic is a type of plastic that has the ability to conduct electricity. Over the past few years, there have been many experiments and studies that aim to make plastic electrically conductive. Plastic’s lightweight and versatile properties make it a very useful material in many kinds of applications. With electronic devices and machinery looking to become smaller and lighter, materials such as plastic must be developed to handle aspects like electrical conductivity.

Advantages of Electrically Conductive Hybrid Plastic

As technology continues to evolve and develop, electrically conductive materials are becoming essential in today’s world. With the introduction of electrically conductive plastic, the number of possible innovations that can be done in electronics and technology has expanded. Here are some of the advantages that they have to offer.

High Conductivity and Temperature Tolerance

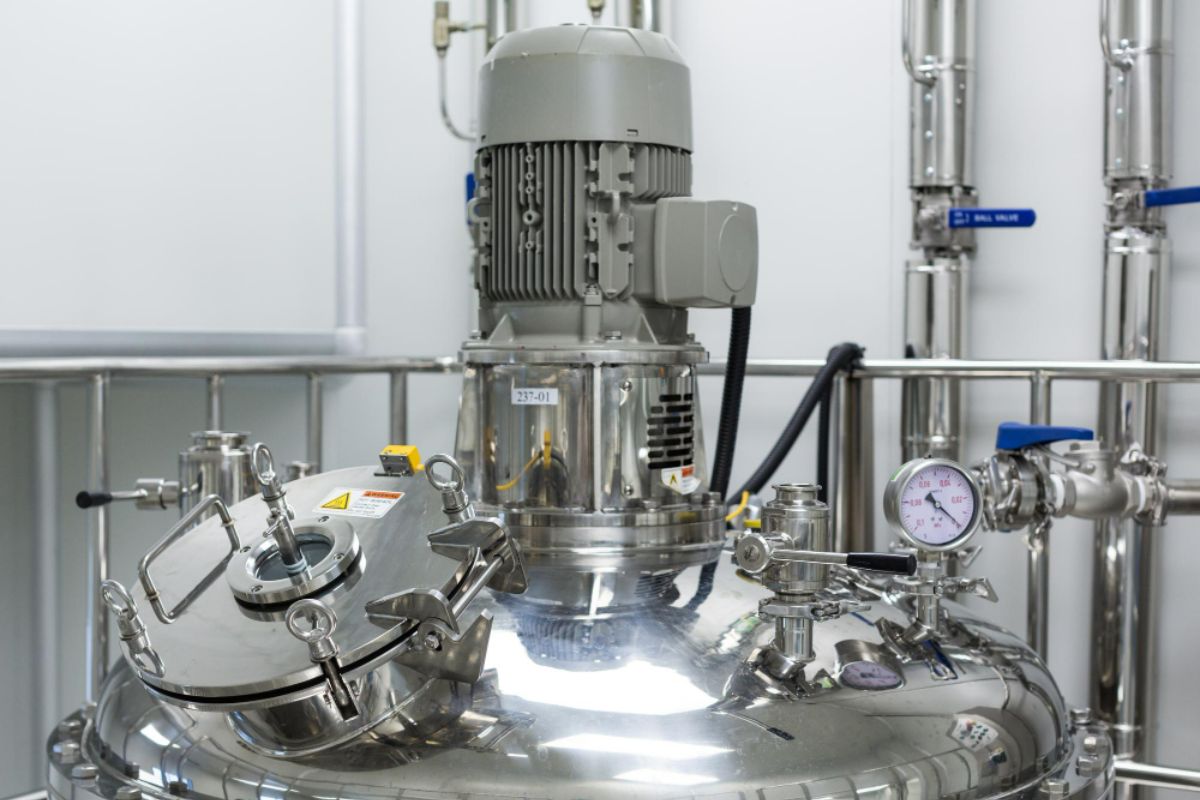

One of the main advantages of electrically conductive hybrid plastic is that they have high conductivity and temperature tolerance. This type of plastic is designed to have the ability to conduct electricity, making it useful for different kinds of electronic equipment and tools. They can also be used in the automotive, aerospace, and consumer electronics industries that have a high demand for smaller and lighter materials.

While electrically conductive hybrid plastic is still vulnerable to extreme temperature levels, their resistance is higher than that of regular types of plastics. Being a type that can conduct electricity, it is critical that it withstands temperatures brought about by electrical activity. Electrically conductive hybrid plastic is a step towards the future for plastics, and these advantages make it a more viable material to use in the years to come.

Lightweight Structure

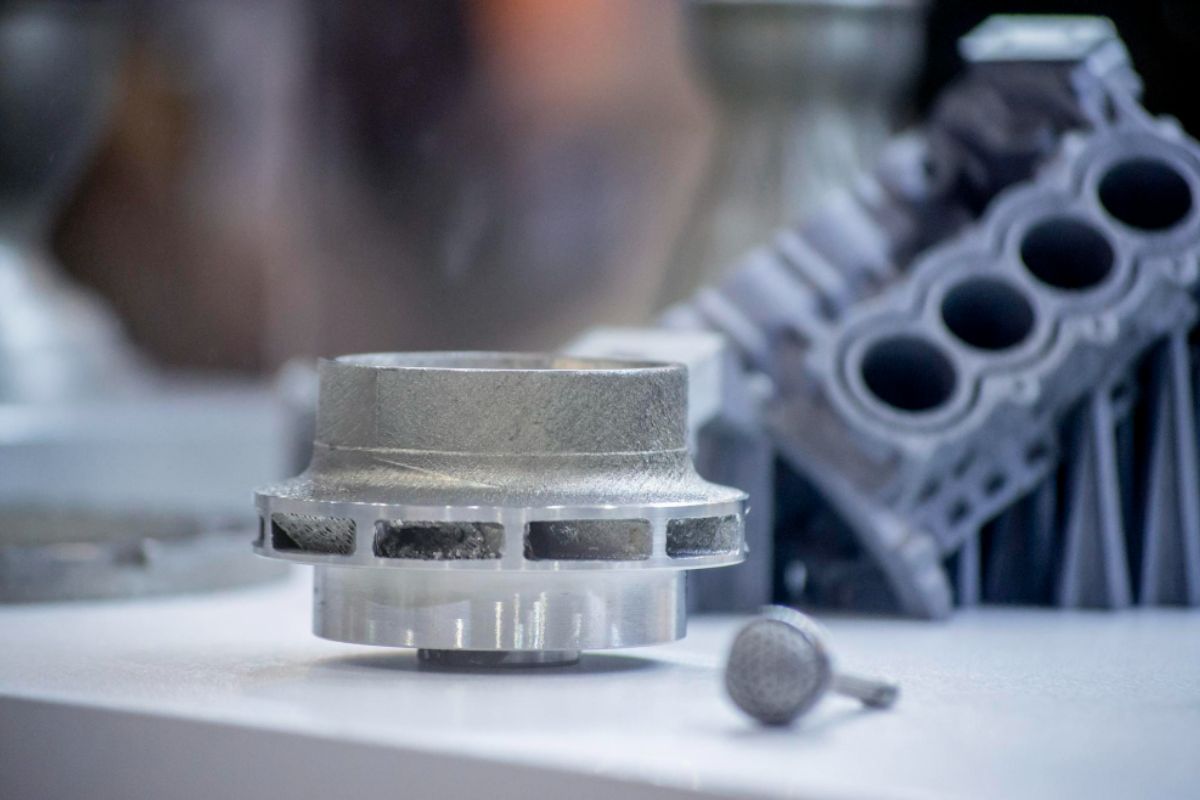

Metals are known for their strength, malleability, and durability, which is why they have been widely used for different kinds of electrical equipment and tools. While metals are great conductors of electricity, one of their major drawbacks is their weight. Its heaviness can cause a number of issues and complications that can affect performance and functionality.

This makes electrically conductive hybrid plastic a more attractive option for electronics manufacturers as they weigh significantly less than their metal counterparts. They are more convenient to move around and you will not have the problem of lifting heavy loads, which can strain both personnel and equipment. Plastic has always been known as a light and flexible material. Giving it an electrically conductive quality makes it an even more viable option in the world.

Cost-Effective

One of the advantages of using plastic in manufacturing is that you have a more cost-effective material that is light and versatile. With this type, most manufacturers can reduce production costs, allowing them to produce more affordable products that retain the same level of quality. Plastics can substitute for other heavy materials such as wood and metal, which are resources that are also limited and expensive.

As the economy continues to become more competitive, manufacturing needs to follow suit and implement new materials that improve production processes while maximizing the budget. When it comes to affordable manufacturing materials, plastic remains one of the more sought-after ones in the manufacturing industry.

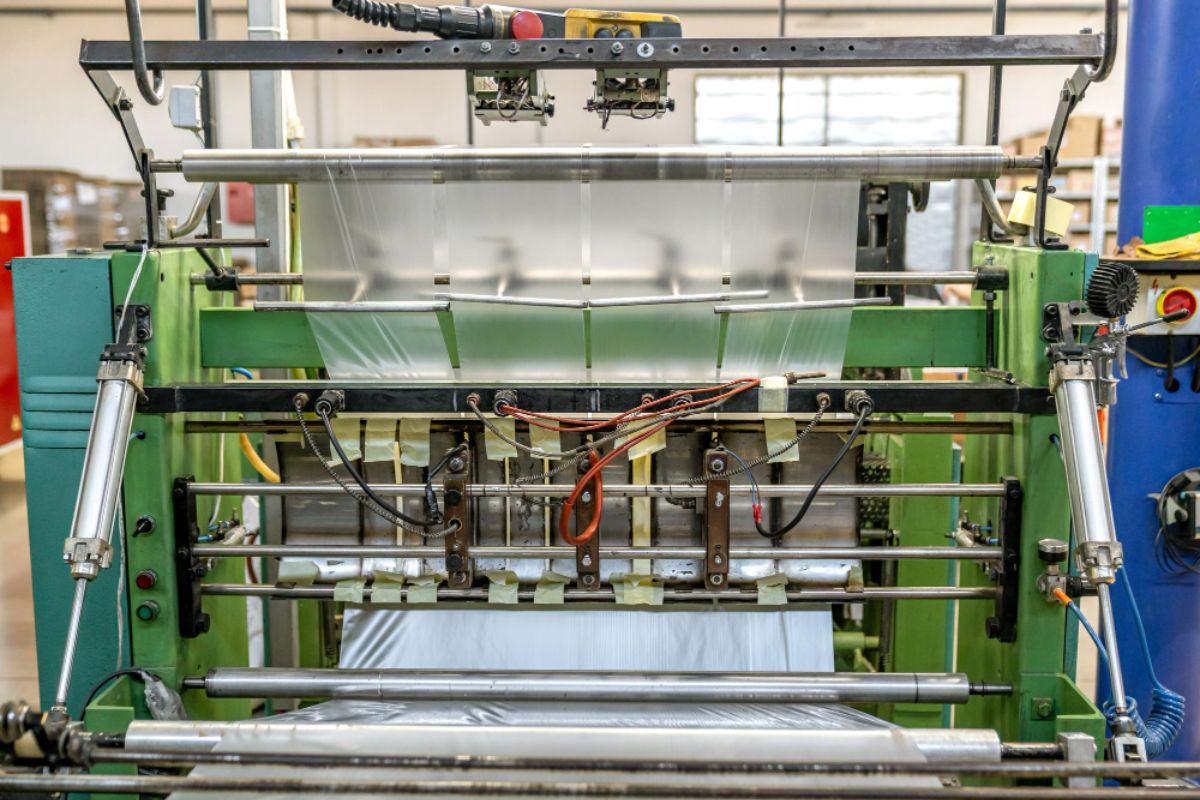

Easy to Produce

Compared to other materials used in electronics and electrical devices like metals, plastic is much easier to produce. The plastic injection molding process is quick. All you need is the mold and the molten plastic. This helps save more production time, while also allowing more products to be produced overall. The manufacturing industry has become consistently competitive, which is why having the ability to produce high-quality products at a more rapid rate provides a huge advantage for any company.

Key Takeaway

Plastic is one of the most abundant materials in the manufacturing industry as it is used to create a wide variety of products. With the introduction of electrically conductive plastics, the material has become even more versatile, providing more opportunities for innovation and new products.