What are the benefits of injection molding?

- Injection molding is resourceful and efficient.

- Injection molding can cut labor costs.

- Injection molding can provide diverse product varieties.

- Injection molding is fast and flexible.

- Injection molding produces a high amount of details on the finished product.

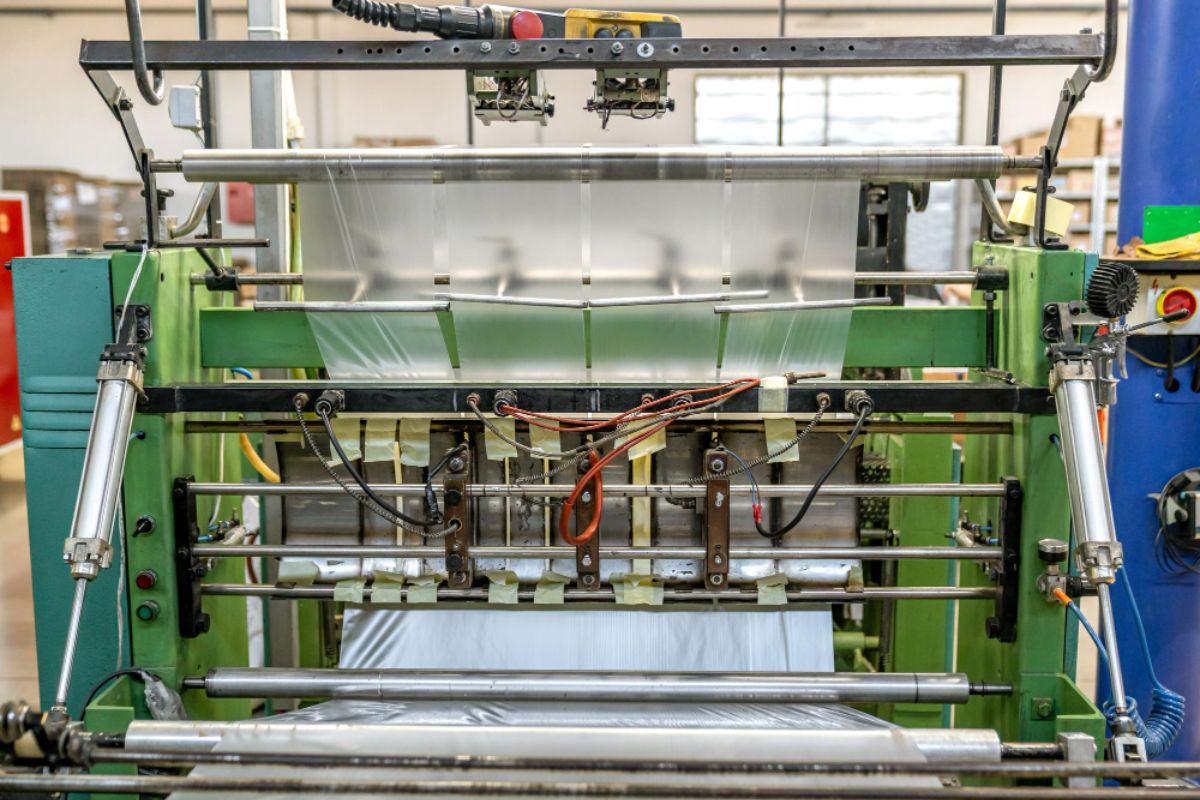

The injection molding industry is one of the largest producers of the products we use on a daily basis. A molding company can produce thousands of products continuously in a single day, thanks to the efficient work of the plastic injection molding machine.

This machine enables manufacturers to be able to mass-produce quality products that can be quickly and widely distributed to places around the world. The convenience of plastic products made molding machines very valuable in the industry. To find out how valuable it truly is, here are some other benefits of injection molding:

It’s Resourceful and Efficient

One of the few things that a plastic injection molding machine is known for is its high efficiency rate when it comes to production. When you are using the machine, you are ensured that you are getting the best results, due to the machine’s ability to produce the same quality product over and over again. The machine also uses a set amount of plastic and ensures that the amount of plastic would be fully utilized during the whole production process.

Low Labor Costs

Since the plastic injection molding machine process is mostly automated, a molding company does not need to use as much manpower compared to other manufacturing companies. The machine only needs a small amount of personnel for maintenance and supervision. This helps lower the cost of labor, as you only get the right amount of staff to help out with the production.

Diverse Product Variety

The amount of products that you can make with an injection molding machine is immense. Since most of the products we use today are made out of plastic, companies can simply craft and mold any type of product, and produce it in the machine. These products include toys, bottles, utensils, tools, and so much more. Simply put, if you can mold it, you can make it.

Flexible and Fast

Other than the diverse product variety, plastic injection molding machines can use different kinds of plastic. These types of plastic vary, from the hard and durable ones, to the soft and environmentally-friendly ones. The machines can handle these kinds of plastic and end up with a quality product altogether. The production of each product also takes a small amount of time, which is around 15 seconds to a minute, depending on the size of the product.

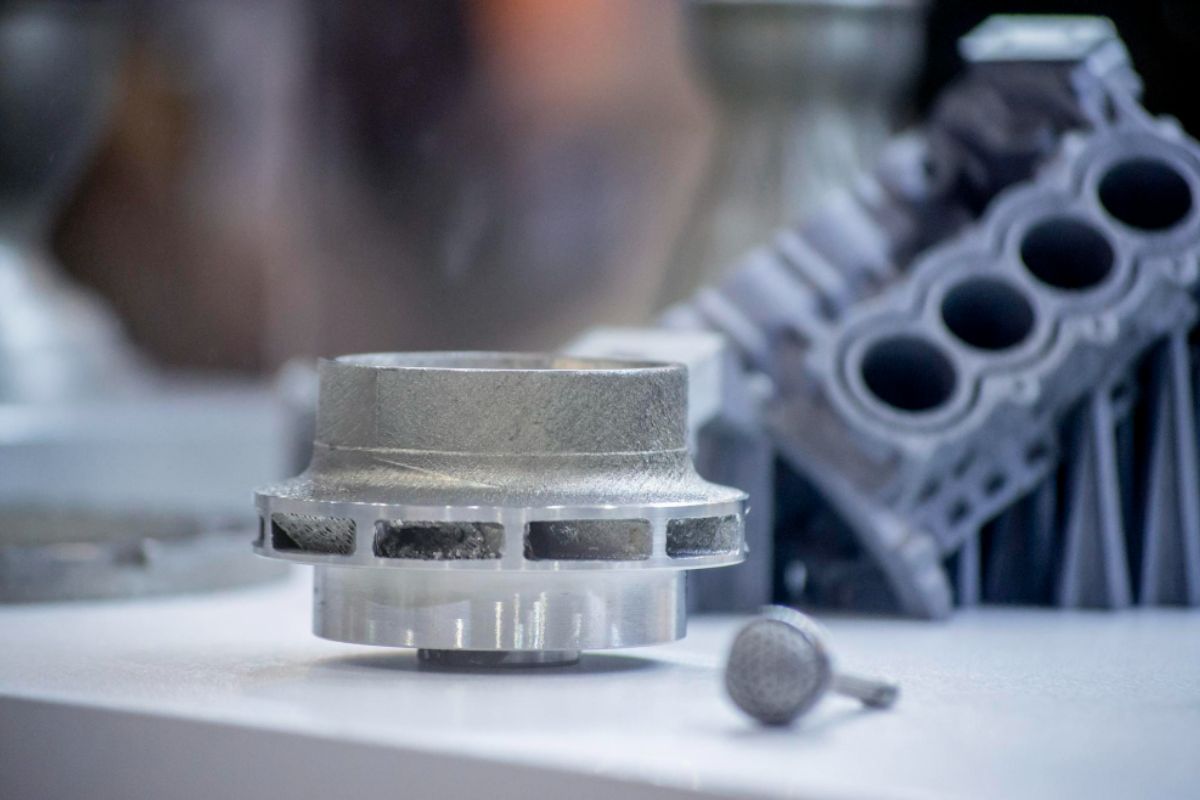

High Amount of Detail on the Finished Product

Since the products that are produced are of high quality, the amount of detail is very high. The machine can produce finished products out of complicated and intricate molds, and still make sure that it remains the highest quality possible.

Key Takeaway

Plastic injection molding machines are some of the most widely used machines around the world. With the demand of plastic products remaining high, these machines are able to address the need and produce the best products available.

The next time you purchase a plastic product, that product most likely came from one plastic injection molding machine. With the industry growing on continuously, it is expected that plastic molding will still be one of the most profitable industries in the world.