Precision plastic injection molding creates complex plastic parts and products with a high degree of accuracy and intricate details. Unlike conventional injection molding, it utilizes specialized molds and high-tolerance engineering to achieve this level of detail. This enables manufacturers to create plastic components that replace high-precision metal parts in various applications.

Richfields Corporation caters to various Original Equipment Manufacturer (OEM) needs with our plastic injection molding services in China. Our machinery boasts clamping forces (60 to 3300 tons) to accommodate projects of numerous sizes and complexities.

From parts requiring strict tolerances and meticulous quality control to cost-effective general-purpose components, we offer flexibility to match your specific needs. This adaptability, coupled with our expertise in handling single custom parts, high-cavity molds, over-molding, and unscrewing tools, positions us to deliver high-quality plastic injection molded components for diverse production requirements.

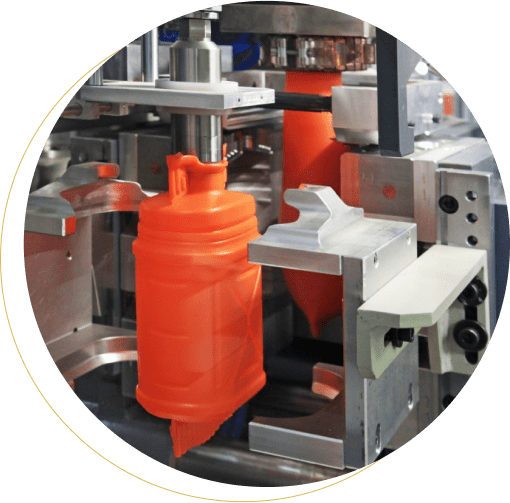

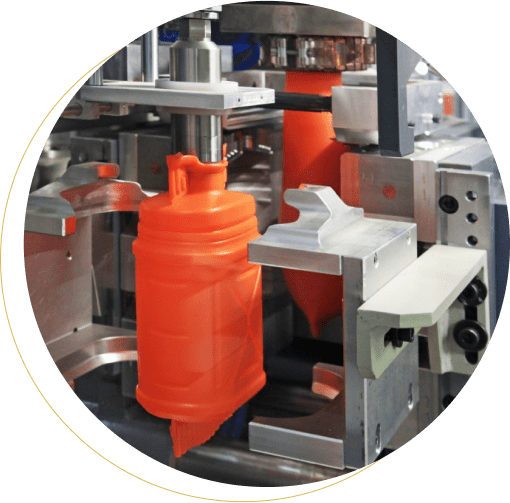

Precision plastic injection molding service in China takes the core concept of injection molding and elevates it to a whole new level of detail and control. The process starts with meticulous design and engineering, using specialized molds built to extremely tight tolerances. This ensures the final product precisely matches the intricate details designed in the mold.

Molten plastic is then injected under high pressure, filling every crevice of the mold and solidifying it into a near-perfect replica. Once cooled, the parts are carefully ejected and undergo rigorous quality checks to guarantee consistent accuracy and performance for every single piece.

Precision molding emphasizes high-precision mold design, demanding stricter measurements and testing throughout the process. Specialized materials like engineering plastics and thermoplastic elastomers are often used to achieve superior mechanical properties, exceptional surface quality, and product stability.

Precision plastic injection molding is a vital industry in China, driving various sectors such as automotive, electronics, and healthcare. It ensures high-quality, accurate, and complex plastic parts at competitive costs. China’s advanced machinery and automation enhance production efficiency, while rapid prototyping capabilities provide a speed-to-market advantage.

Their strategic location and robust infrastructure facilitate timely global delivery, integrating seamlessly into the global supply chain. Their ability to produce intricate designs and micro-components supports cutting-edge innovations. Leveraging their precision molding capabilities allows businesses to achieve superior product performance and competitiveness in the market.

Injection molding has long been a cornerstone of manufacturing, but advancements in technology have opened many doors. Precision plastic injection molding in China takes this process to a whole new level, revolutionizing the way we manufacture products across a wide range of industries.

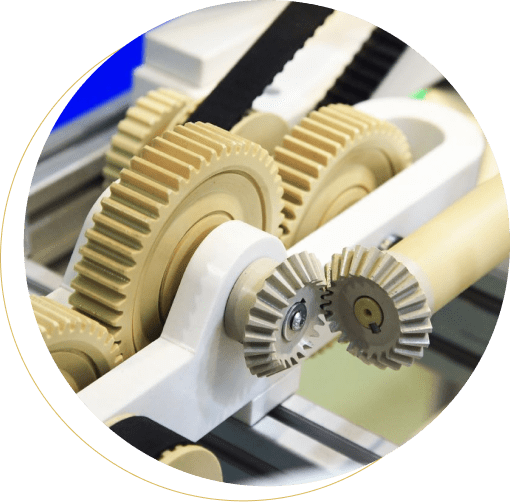

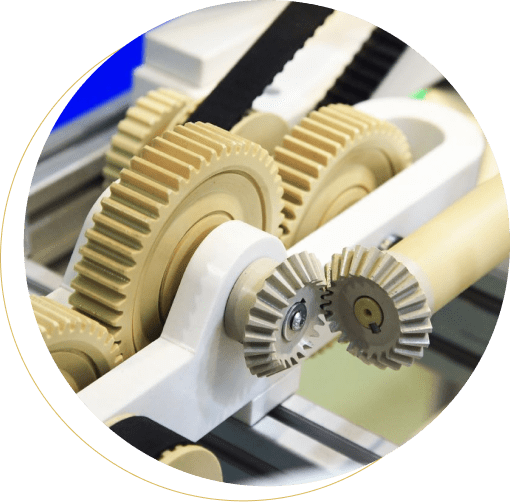

Precision molding plays a crucial role in creating high-performance automotive parts. From intricate gear components and lightweight engine parts to complex interior components and durable exterior trims, this technique allows for precise shaping and tight tolerances, ensuring optimal functionality and weight reduction.

The ability to create sterile, biocompatible plastic parts with high accuracy is vital in the medical field. Precision plastic injection molding services in China enable the production of complex medical devices such as syringes, microfluidic components, and even intricate prosthetic parts, all requiring exceptional precision and surface quality.

While not as prominent as the others, precision molding finds applications in the construction industry as well. This can include creating lightweight yet durable building components like ventilation systems or intricate moldings for architectural applications.

The miniaturization and increasing complexity of electronic devices demand high-precision components. Precision plastic injection molding in China allows for the creation of intricate housings, connectors, and circuit boards with minute details, ensuring optimal performance and reliable device functionality.

When it comes to realizing your vision for a specialized plastic part, choosing the right injection molding company is crucial. A skilled and experienced partner will possess the expertise to design the optimal mold and establish the ideal molding conditions.

With over 20 years of experience collaborating with clients across diverse industries in the world, Richfields Corporation stands out as a reliable partner for your precision plastic injection molding needs in China. We offer a comprehensive range of services to bring your design to life.

We offer comprehensive support for your precision plastic injection molding project. Our team combines technical expertise, engineering knowledge, and creative thinking to assist you throughout the entire process. From the initial stages of product design and prototyping to final packaging and logistics, we provide invaluable guidance and innovative solutions, ensuring a smooth and successful project from start to finish.

Precision plastic injection molding in China requires meticulous planning and consideration of numerous factors during the mold design stage. These include the type of mold base, the specific steel used, and a range of other variables. Our dedicated team collaborates with you to understand your specific product needs and design the perfect mold for optimal results.

Designing both the plastic parts and the molds with this specific process in mind is crucial to achieving cost and time efficiency. We offer prototyping services to facilitate this process, allowing you to refine your part design and mold configuration through multiple iterations before finalizing production. This minimizes potential issues and ensures a cost-effective, high-quality outcome.

In addition to our core services of precision plastic injection molding services in China, mold design, and prototyping, Richfields Corporation offers a comprehensive suite of value-added secondary services to streamline your product development process. Our post-molding machining, pad printing, assembly, and packaging ensure your plastic parts are finished and ready for immediate market launch.

We leverage our state-of-the-art facilities, boasting ISO 9001 certification and a wide range of plastic injection molding equipment (from 65 to 2200 tons) to accommodate projects of all sizes, such as medical equipment, industrial tooling, automotive, sports, and consumer goods. Our in-house tool shop allows for ongoing maintenance of client molds, ensuring high-quality plastic parts for years to come.

Richfields Corporation offers industry-leading expertise in precision plastic injection molding services in China. Our collaborative approach, from design optimization through prototyping and production, ensures you receive high-quality, cost-effective parts that meet your exact specifications. Contact us today to discuss your project and unlock the potential of precision for your next manufacturing endeavor!