High-Precision Plastic Molding & Fast, Reliable Service

Trust Richfields for top-quality plastic injection molding with precision and speed. Our expert team delivers tailored solutions, ensuring on-time delivery and exceptional results every time.

Founded in 2000, Richfields Corporation specializes in high-quality plastic components and mold manufacturing, producing over 500 molds annually. With over 26 years of expertise, the company emphasizes precision, efficiency, and innovation. Now expanding into the U.S., Richfields remains committed to quality, competitive pricing, and tailored manufacturing solutions.

Richfields has in-house Tool shop working 24 hours, in-house injection molding facility with 88 injection machines ranging from 60 Tons to 5,000 Tons, in-house Painting and Assembly lines. We can produce plastic parts up to 3 meter in part length and up to 50kg part weight.

We are also ISO9001, IATF16949, ISO14001 and GMP FDA certified.

Learn More

Gas Assist Injection Molding is the process in injection molding wherein nitrogen gas is injected through controlled high pressure into the tool during the injection process. Richfields usually uses this process for plastic parts that are considered bigger or thinner than usual, under industry standards.

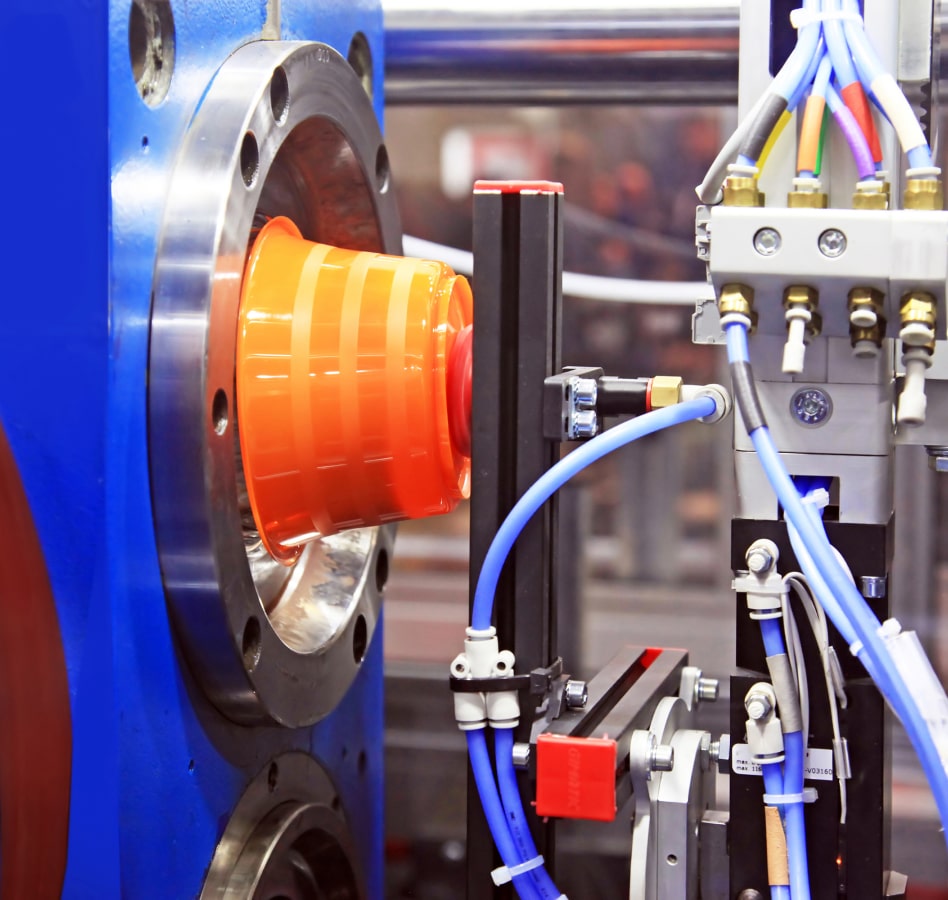

Richfields Corporation uses decades of experience in manufacturing unscrewing plastic injection molds. The output is molds that are used for the production of internal threaded plastic injection parts. External threaded plastic injection does not need to be produced using unscrewing injection molds.

We specialize in plastic injection molding for a wide range of OEM applications, offering machines from 60 to 5,000 tons to accommodate diverse production needs. Whether creating tight-tolerance components with strict quality control or cost-effective general plastic parts, our flexible approach ensures consistent, high-quality results for every project.

Richfields offers advanced spray painting and pad printing services, utilizing state-of-the-art technologies like tunnel conveyors and multi-color applications to enhance efficiency and reduce costs. With 10 spray paint chambers, 12 screen printing tables, and 6 pad printing machines, we deliver precise, high-quality finishes on various surfaces, including irregular and cylindrical shapes.

Richfields offers assembly services for plastic and metal components, including sourcing and integrating mechanical parts and circuit boards. We cater to industries like industrial lighting, consumer retail, and electronics, continuously expanding to support new technologies and product applications.

Richfields designs and manufactures custom packaging for plastic injection molded parts and mechanical assemblies, including blister packaging, color boxes, foam inserts, and shrink wrapping. Early coordination on packaging needs ensures cost efficiency and prevents misunderstandings in production.

Our specialty in Large Part Injection Molding lies in producing durable, high-quality plastic components for various industries, including automotive, furniture, and industrial applications. We utilize advanced molding techniques and state-of-the-art machinery to ensure precision, strength, and consistency in every part. Our expertise allows us to handle complex designs and high-volume production while maintaining cost efficiency and minimal waste.

With a focus on innovation, we offer customized solutions tailored to specific client needs, ensuring optimal performance and longevity. Backed by years of experience, we guarantee reliable, large-scale manufacturing that meets stringent quality standards and industry demands.

Learn More

Our expertise in Injection Molding in China ensures high-quality, cost-effective plastic components tailored to diverse industries. With advanced manufacturing technology and an optimized supply chain, we achieve rapid production without sacrificing precision. From automotive to consumer goods, we customize solutions to meet unique specifications, enhancing both durability and performance.

Our team prioritizes efficiency, optimizing mold designs to reduce waste and improve overall sustainability. Through strict quality control and scalable production capabilities, we provide reliable solutions that support global manufacturing needs.

Learn MoreRichfields was a part of the successful PDMEX 2019 event, showcasing its services to potential partners and clientele. Know more about Richfields, along with its products and services, by clicking here.

No posts found.

Overview This article explores the essential considerations when selecting a reliable supplier for your retail fixtures. From understanding the benefits of using plastic over traditional materials to evaluating suppliers based on quality, customization, lead times, and cost-efficiency, we help you make informed decisions. Learn how Richfields Corporation, a leading provider of large part injection molding […]

Read more

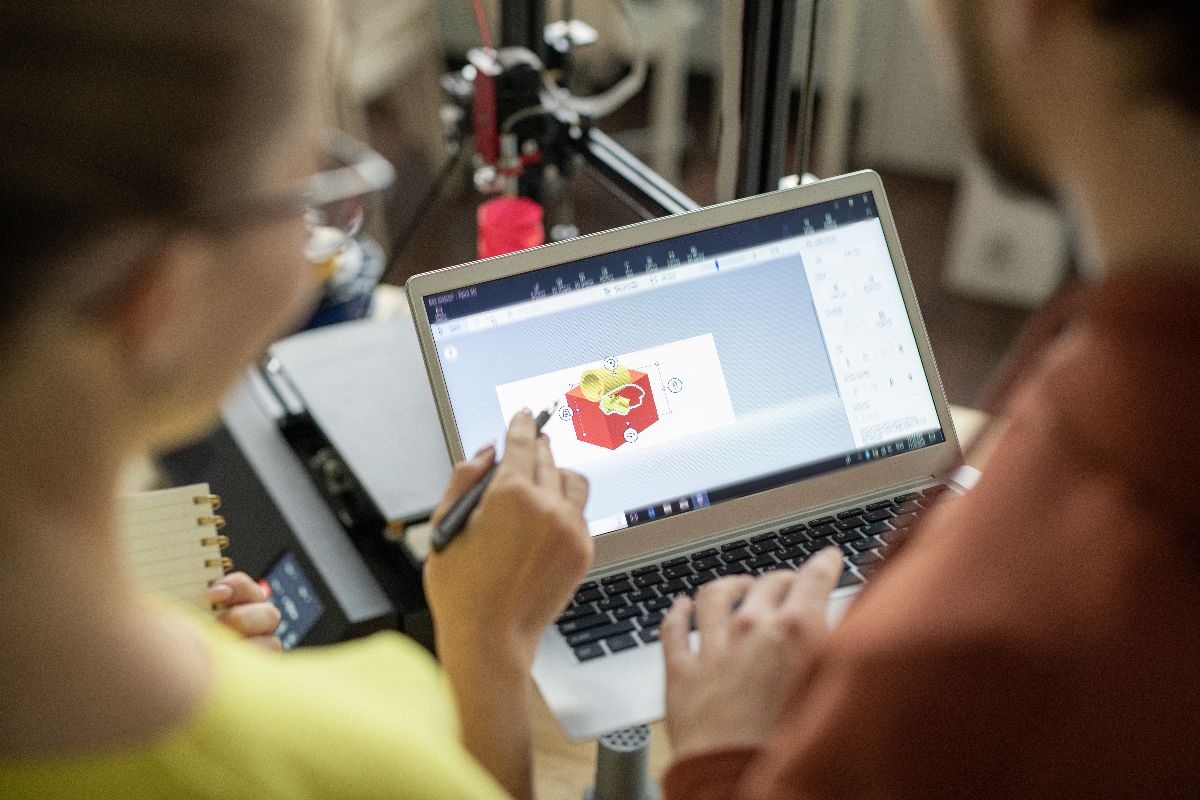

How can you use 3D printing in injection molding? Rapid prototyping 3D-printed molds Conformal cooling channel inserts Tooling component fabrication Mold repair and modification Overview 3D printing has become a transformative tool in manufacturing, particularly when integrated with injection molding processes to improve efficiency and production agility. From rapid prototyping and creating 3D-printed molds to […]

Read more

What are the signs you should move to injection molding? When you need to consistently produce large volumes of identical parts If your current manufacturing procedure is costly When precision and complexity are required in plastic components When there’s too much material waste during production If your products have to meet strict regulatory standards When […]

Read more

What are the benefits of using high-quality resin in injection molding? Improved part strength and durability Consistent quality across production runs Better aesthetic appearance Enhanced chemical and heat resistance Reduced defects and lower scrap rates Overview The benefits of using high-quality resin in injection molding extend far beyond aesthetics, impacting product durability, precision, and production […]

Read more