Latest Blogs

6 Food-Grade Plastic Resins and Their Applications

What are common food-grade plastic resins? Polyethylene Terephthalate (PET) Polypropylene (PP) High-Density Polyethylene (HDPE) Low-Density Polyethylene (LDPE) Polycarbonate (PC) Polystyrene (PS) If you’re interested in creating your plastic food packaging, then it’s essential that you’re using materials that can come into contact with your food without any adverse side effects. For plastic injection molding, those […]

Read more

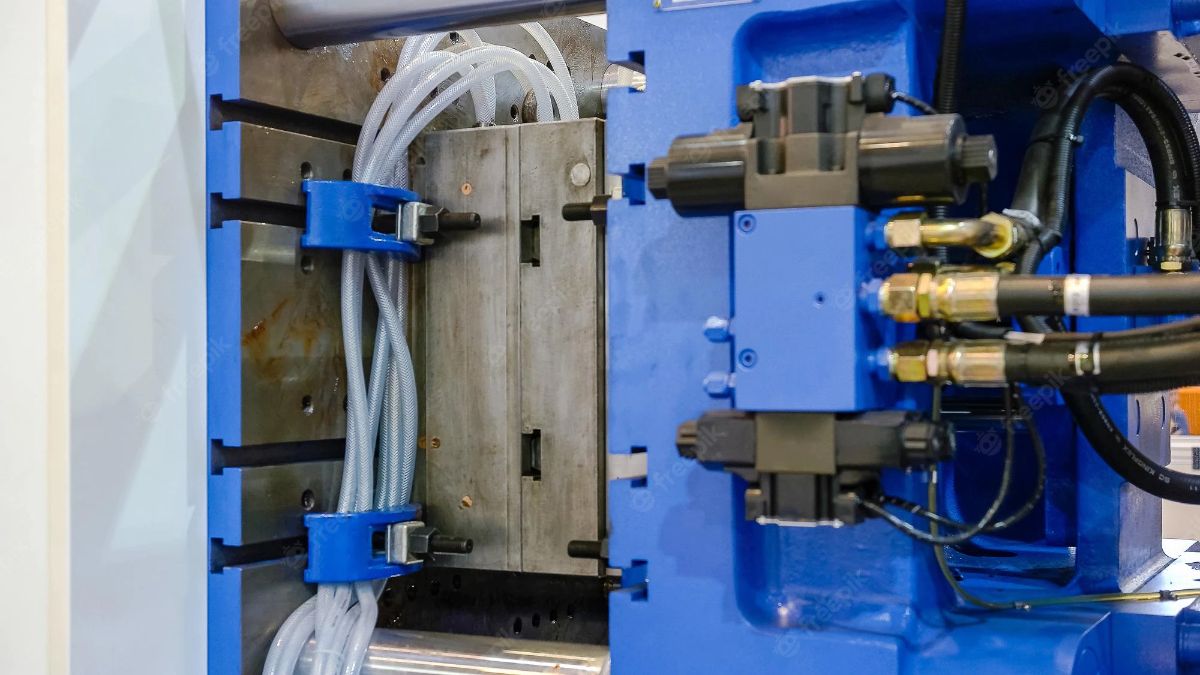

6 Benefits of Plastic Injection Molding for Construction

What are the benefits of plastic injecting molding for your construction project? From one-size-fits-all to mass production Any dimension, any specification Outstanding insulation Competitive pricing Long-term solutions Finishing touches We can see how excellent each work done by the construction industry is today. From the supermarkets to the houses we live in, the roads we […]

Read more

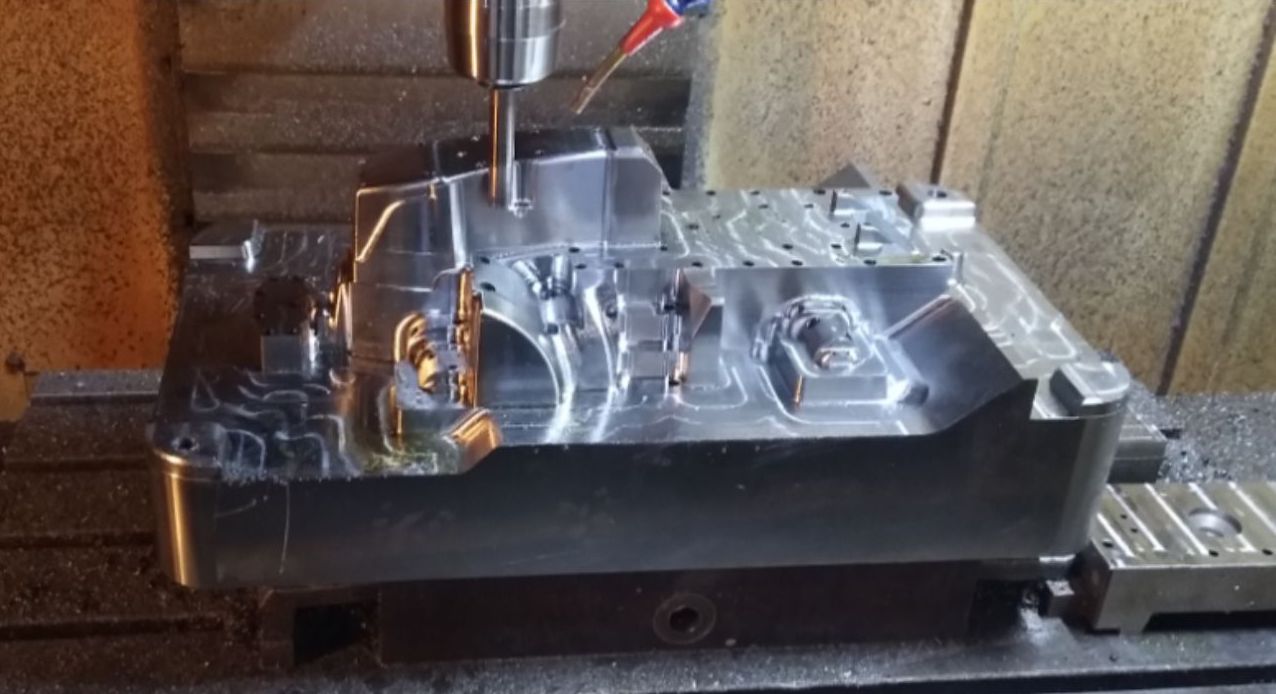

What is Precision Injection Molding? 5 Things to Know

What is precision injection molding? Creates precise plastic components Materials should have a low shrinkage capacity Rely on the precision injection mold A slow and steady process Uses polymer optics Many molding processes are known to mass produce products that are used in daily life. However, various industries have parts and pieces that are too […]

Read more

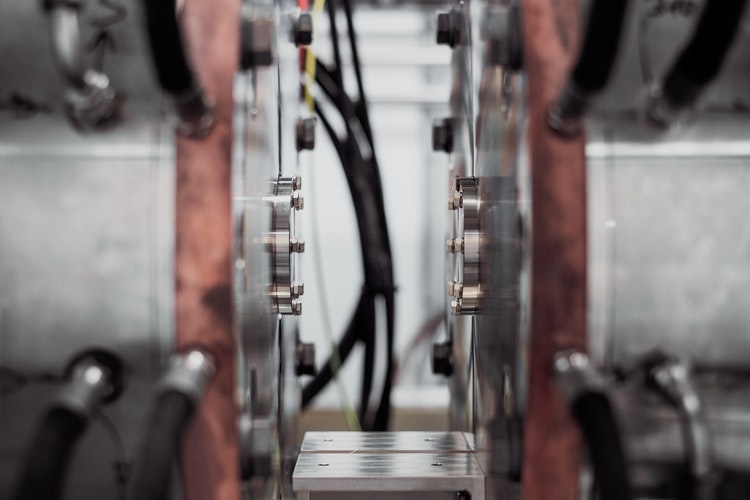

5 Amazing Benefits of Using Family Molds in Injection Molding

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read moreOther Blogs

The Power of Packaging in Marketing and Branding

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more

Improving Accuracy in Manufacturability by Incorporating the Best Practices in Injection Molding

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more

How to Pick the Right Material in Medical Device Design with a Molding Company in China

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more

4 Ways Injection Molding Companies in China Changed the Medical Industry

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more

Global and China Injection Molding Report Predicts Bullish Future for the Industry

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more

Things You Need to Know About the Different Injection Molding Processes

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more

5 Most Commonly Used Resins for Plastic Injection Molding

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more

Advantages You Can Get from a Precision Molding Company in China

What are the benefits of using family molds in injection molding? Lower mold cost Easier ordering Low-volume production potential Improves production rate and cost-per-part Ideal for prototyping use Using injection molding for your plastic parts and products entails molten resin being inserted into a hollow mold cavity. This then cools and takes shape — resulting […]

Read more