Why is air assist essential to laser engraver?

- It improves efficiency

- It is a good investment for businesses

- It reduces the production cost

- It gives high-edge quality

- It gives cleaner finishing

- It increases safety

If you want an improved product surface texture while also reducing the use of plastic materials, applying an air assist is the best option. This makes molding production faster, more efficient, and more cost-effective for you.

Have you ever wondered why many businesses are flocking into air assist for laser engraving today? This blog will tell you all the reasons why air assist is essential to the laser engraver.

What Is Air Assist?

Air assist is a type of injection molding service that injects nitrogen gas or controlled high-pressure air into your product during the laser engraving process. The two most commonly used assist gasses for this injection are oxygen and nitrogen, while the best alternative to these two is high-pressure air.

Implementing an air assist minimizes and disappears heat around the laser head, achieving a better laser engraving result. It also helps to remove debris while also avoiding your product from getting burned.

How Does Air Assist Work?

The function of air assist starts when a light beam is not enough to engrave lasers. It was found out in the 90s that it also needs an injection of the gas nozzle at the laser head to help balance its production.

When air assist is finally implemented in a laser engraver, it forms a chemical reaction called exothermic which releases energy through heat and light. And with the application of oxygen, nitrogen, and high-pressure air, makes production easier, faster, and cleaner.

Before, it was only oxygen that could be used with air assist for laser engraving until it was overcome by nitrogen, which provides a cooler engraving and cleaner edges.

Businesses and industries found this successful until it was known that high-pressure air makes it better and a good choice for an economical option that can also compete with nitrogen and oxygen’s attitude for air assist.

After all, the air has 80% nitrogen and 20% oxygen.

Why is Air Assist Essential To Laser Engraver?

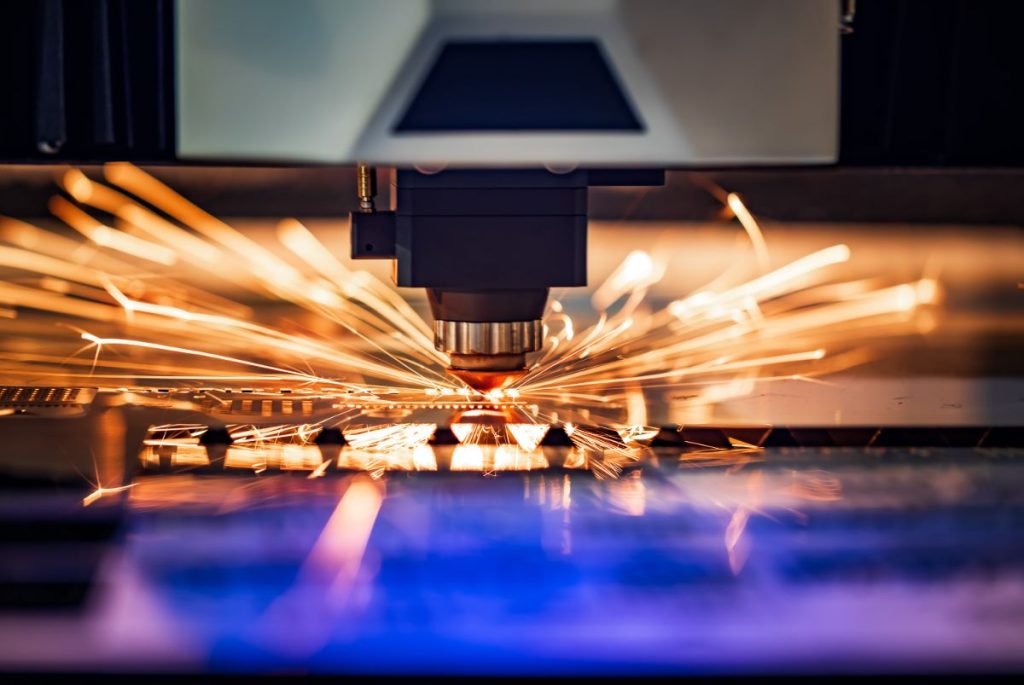

From the ’90s up until today, air assist has become popular as it enhances laser engraving for materials such as aluminum and stainless steel. Some of the reasons why air assist is essential to laser engraver are:

It improves efficiency

The use of air assist helps fasten the laser engraving production. Nitrogen provides faster engraving for products thicker than ten gauges, while high-pressure air is estimated to be 3% faster than nitrogen in the mild steel range of 0.135 inches and thinner.

Meanwhile, it’s 22% faster for stainless steel from 0.750 to 0.036, proving how essential air assist is for a laser engraver. And, it’s 14% faster for aluminum from 0.190 to 0.032 inches.

It is a good investment for businesses

Since using high-pressure air for an air assist is an economical move for businesses, it’s a great investment for companies producing laser engravers. It helps them upgrade or expand their laser engraving capabilities, as well as achieve a cleaner and smoother engraving.

It reduces the production cost

Using an air assist for laser engraving is less costly, especially when you’re using high-pressure air. There are some cases where it costs almost a hundred percent of production when using oxygen or nitrogen. So to save you enough money, it’s best to look for an affordable and high-quality air assist service. Richfields is dedicated to helping you with our very own air assistance service.

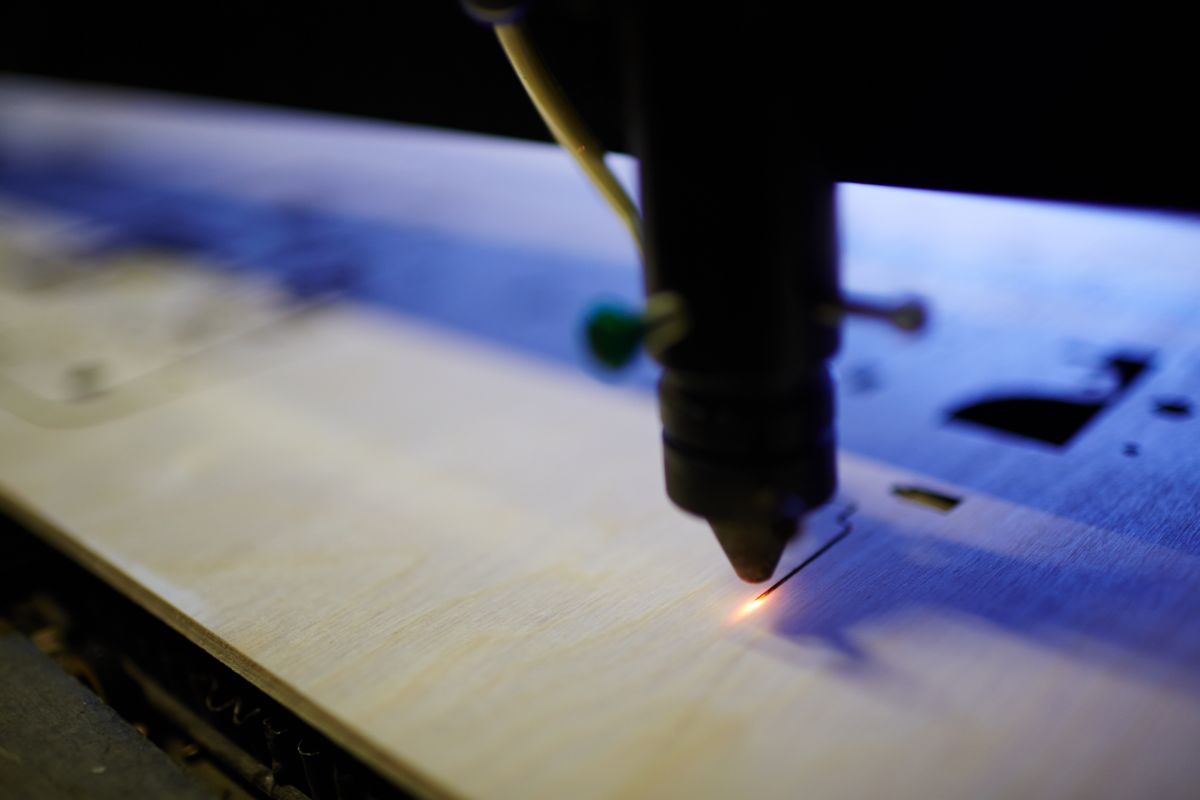

It gives high-edge quality

Using high-pressure air for laser engraving gives an edge to quality finished products for materials such as wood, acrylics, powder coatings, and other materials.

It gives cleaner finishing

When using air assist, it helps to reduce or eliminate oxide formation, which is the burn marks that appear on your laser engraved products. So instead of investing in other services for laser engraving that can’t meet the qualities that air assist has, don’t hesitate to try air assist now for cleaner finished products.

It increases safety

Businesses are choosing air assist for laser engravers because it lessens the risk of debris causing a fire. Also, the laser beam and heat it produces make the combustible materials quickly blown away.

What Happens When You’re Not Using Air Assist?

When your laser engraver is running, it produces debris and smoke from its heat, which is dangerous as it can cause a fire. And the smoke it produces has negative effects on your health, your surroundings, and your final products such as:

- Decreases the strength and increases inconsistencies in your laser

- Creates residue around the laser engraver

- Produces chemicals and discoloration that can affect your respiratory system

Key Takeaway

There are many benefits and reasons why air assist is essential to a laser engraver, and the most important thing is there’s the best China injection molding company that can provide you with that to help you reach your desired product.

If you’re looking for a high-quality air assist service, message us at Richfields. We make and optimize this process for our clients. Contact us here today to assist you with your injection molding needs.