What are the things you need to remember in setting barrel temperatures for injection molds?

- Measure barrel temperature

- Thermocouple placement

- Temperature sensing

- Temperature setting

- Temperature recording

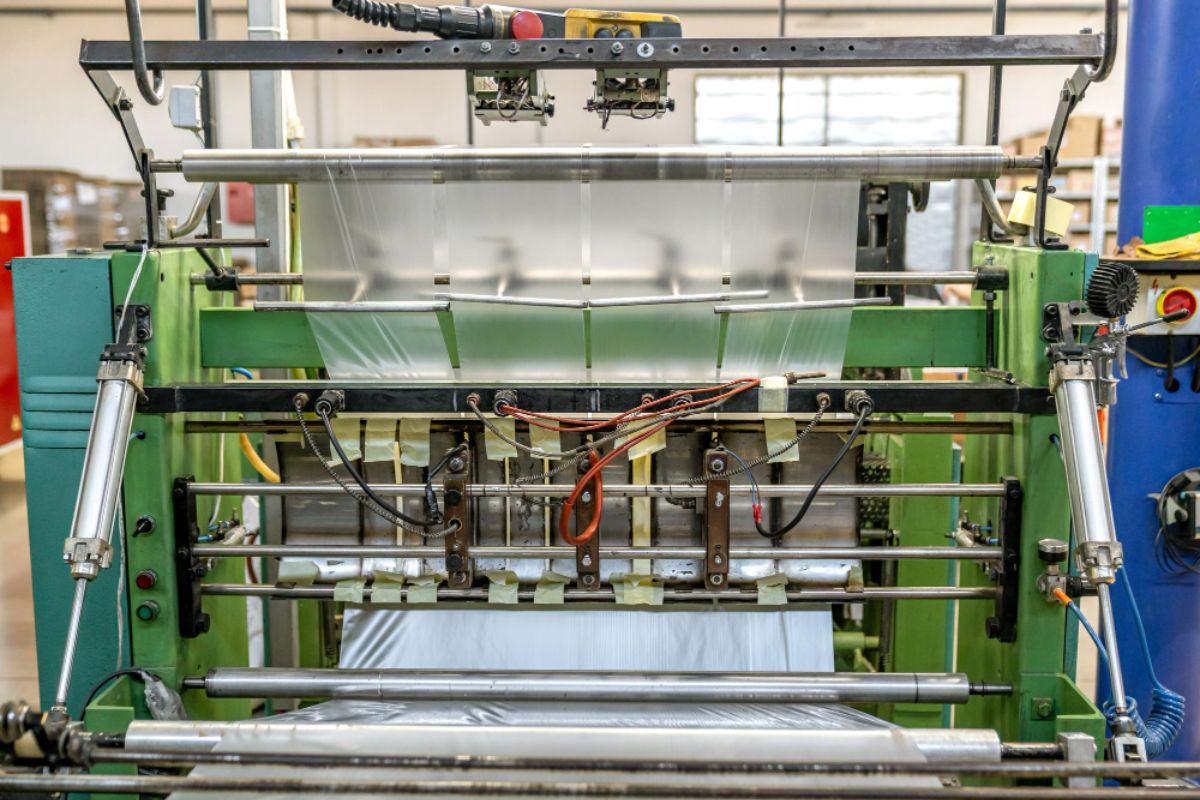

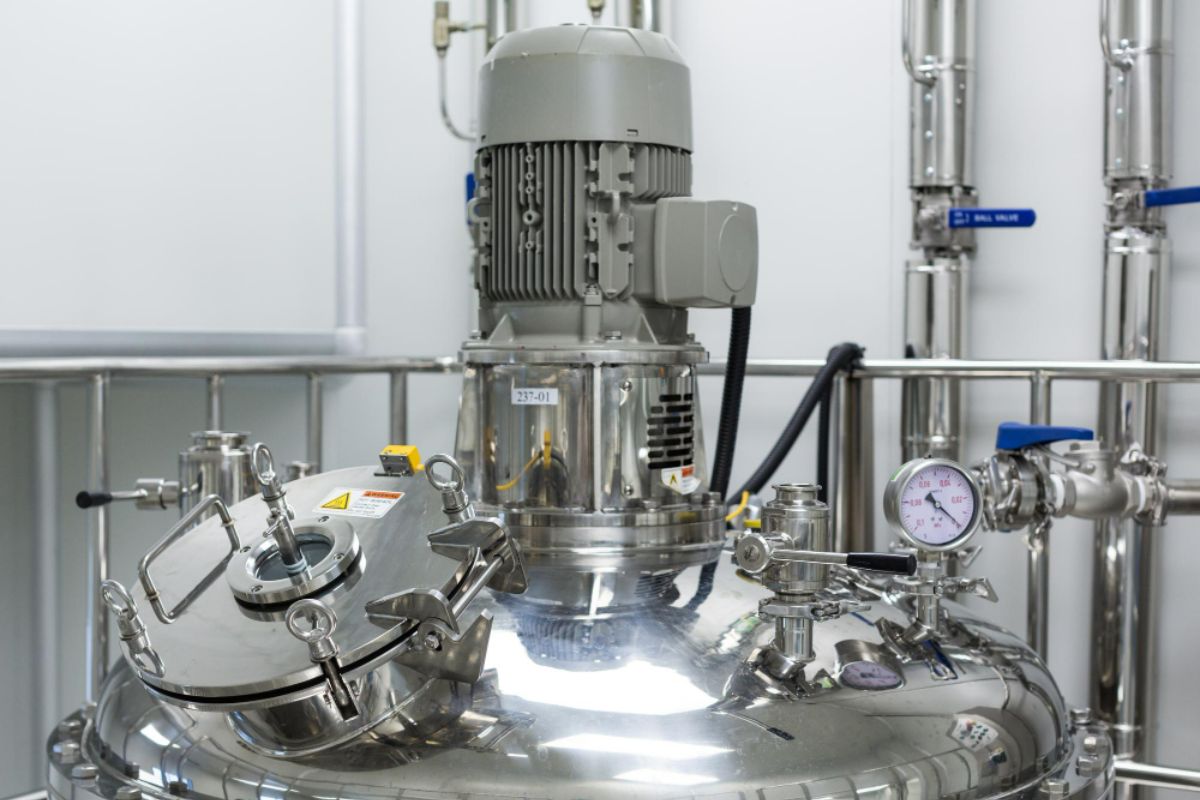

Setting the barrel temperatures of injection molds from China is an integral part of the production process. Plastic molding companies make sure that the processes they employ coincide with the design requirements for the product, and this includes temperature control. It can be quite difficult to understand the main processes that go into plastic molding manufacturing, but knowing the basics of this kind of production will benefit you in the long run.

The cost of injection molds in China are well-thought of and it is fair to those who will be employing the service since many considerations have to be taken into account to achieve the design. When it comes to custom plastic molding, the design requirements should be strictly followed as it leads to the overall functionality of it all. Just know that there are steps in making the barrel temperature setup a success, check them all out there!

Measuring Barrel Temperature

The importance of injection molding from China in the process of manufacturing relies greatly on the accurate measurement of the barrel temperature. The process of measuring the barrel temperature will be useful for the overall result of the production. However, in order to achieve the optimal barrel temperature, you have to be reminded that the temperature zones on the barrel should be consistent throughout. Temperatures are usually measured in Celsius or Fahrenheit.

Avoid zone-temperature override which happens when one of the temperature zones on the barrel of the plastic injection molding machine because this will result in unexpected defects in the product. One way to control the zone temperature is to cycle between the on and off button of the temperature controller. This way, you are able to know if you are close to achieving the optimal temperature for the process.

Thermocouple Placement

If you ask your partner plastic molding company about the most crucial part of setting barrel temperatures in plastic mold manufacturing, they are bound to tell you about thermocouple placement and contact area. A thermocouple is a thermoelectric device that is used for measuring temperature. It consists of two wires made from different metals connected at two points. In thermocouples, the voltage running between the two junctions is proportional to the temperature difference in producing plastic parts.

It is essential that thermocouple placement is discussed upon production because it makes all the difference in improving barrel-temperature measurement and control. It may seem simple to measure barrel temperature, but considerations and strict compliance with the design requirements are needed in order to make a satisfactory result.

Temperature Sensing

This step is also crucial in setting barrel temperatures for plastic products. Injection mold suppliers in China ensure that the parts of the production process are well-maintained and efficient to work on a project. Temperature sensing makes use of this capability as this process is done by further utilizing thermocouples on plastic injection molding machines. Temperatures are sensed by seeing if the thermocouple is calibrated at a stable temperature, also known as the reference temperature. This allows the simple and accurate measurements of the temperatures.

Small electrical signals are generated when one end of the barrel is hotter than the other. A thermocouple consists of two different wires joined at each end. More heat generated means that the electrical signal is greater. Temperatures are sensed using thermocouples on most injection molding machines.

Temperature Setting

Employing temperature setting in plastic injection molding suggests that one begins with the lowest settings for the processing of a specific grade of material. Injection barrels should be divided into zones for easy temperature setting, recording, and control. Keep in mind that to achieve optimum temperature setting, you can also set them to the same value. The first zone temperature should start with a lower value if you are working alongside higher temperatures or if the cycle times are long. Doing this will prevent premature molding defects like bridging and melting. Before starting the injection molding process, you should ask your supplier if the barrel, mold, hopper block, and the hydraulic oil are all set to the correct temperatures.

Temperature Recording

Injection molding processes need to be properly set according to the desired temperature. It should then recorded by indicated machine setting record. The temperature recording will include melt temperatures, mold temperatures, water temperatures, and oil temperatures. The increasing number of temperature measuring point should also be indicated.

There should also be an integration of an instrument that touches upon the variety of probes together with an electronic, portable temperature sensor or thermometer which can be useful in the injection molding process. Recording the temperature will also be useful in case you want to use it for future projects and for research purposes.

Key Takeaway

These are just some of the most integral parts that you should know in setting barrel temperatures in injection molds. This knowledge will help you be more involved in the manufacturing of your product and it will be key to assessing the process that your supplier might overlook. Use this as a guide so you can ask the right questions and be rewarded with efficient solutions.