What are the global impacts of injection mold makers on automotive manufacturing?

- Enabling complex and lightweight designs

- Driving cost-effectiveness in mass production

- Facilitating the use of advanced materials

- Supporting global supply chains

- Impacting innovation and customization

Overview

- Injection mold makers are key to producing lightweight, complex, and fuel-efficient components for the automotive industry, improving performance and reducing production costs.

- They offer cost-effective mass production by reducing per-part costs and utilizing automation to enhance production output and efficiency.

- They also enable the use of advanced materials, support global supply chains, and drive innovation and customization in automotive manufacturing.

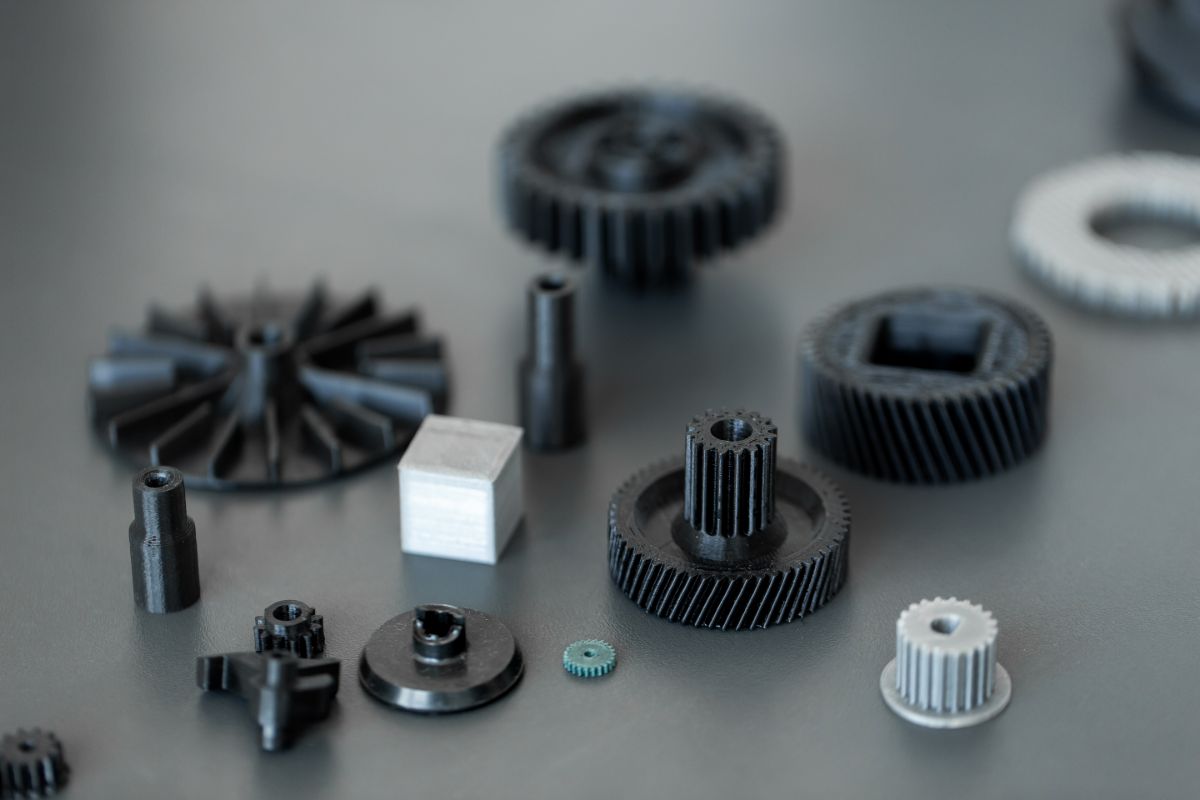

As the demand for advanced vehicle technologies grows, so does the need for high-quality plastic molds that meet industry standards. This is where injection mold makers come in — a popular and trusted way of producing precision-engineered components in the automotive industry.

In this article, we’ll explore the significant impact of injection mold makers in the automotive industry, and how they help automotive companies stay competitive by supporting the development of lightweight, durable, and cost-efficient parts.

Enabling Complex and Lightweight Designs

Lighter vehicles mean better fuel efficiency. In fact, replacing metal parts with plastic can reduce a car’s weight by up to 50%, and even a 10% weight reduction can improve fuel economy by 6-8%. That’s why the automotive industry faces constant pressure to make vehicles lighter, more fuel-efficient, and capable of integrating advanced technologies.

Injection molding plays a huge part in making this happen by allowing manufacturers to create parts with complex shapes that traditional methods can’t achieve. Whether it’s intricate curves or integrated features, injection molding lets designers optimize parts for strength, aerodynamics, and functionality, all while cutting down on weight and the number of components needed. This means cars can perform better, look sleeker, and cost less to produce.

Driving Cost-Effectiveness in Mass Production

When the production numbers increase, the cost per part decreases rapidly with injection molding, making it the ideal choice for automakers looking to produce complex parts at scale without driving up costs. This cost efficiency continues to grow as the production scale expands, providing substantial savings.

Additionally, automation plays a key role in reducing costs further. According to the International Federation of Robotics (IFR), the automotive industry has been quick to adopt robotic technology, which can increase production output by 20-30% while cutting labor costs by 10-20%.

While tooling costs can be high initially, the per-part price drops significantly at higher volumes, making injection molding an economically sound choice for high-volume automotive manufacturing.

Facilitating the Use of Advanced Materials

Reports predict that the automotive plastics market will reach $66.8 billion by 2028, as car makers turn to these materials to reduce weight and improve performance — boosting fuel economy by as much as 35%. The role of injection mold makers in this is to make sure that these materials are shaped into the complex parts that modern cars need.

Injection mold makers are the behind-the-scenes experts who design and create the molds that shape these materials into the perfect car parts. They ensure the parts are strong, precise, and ready to perform in real-world conditions. Without them, it would be a lot harder—or even impossible—for automakers to use these advanced materials effectively.

Thanks to their expertise, manufacturers can build cars that are not only lighter and more fuel-efficient but also innovative and stylish, making it more possible for automakers to push the limits of what’s possible with modern materials.

Supporting Global Supply Chains

The automotive industry relies heavily on efficient global supply chains to meet the increasing demand for vehicles. Injection mold makers play a critical role in this by ensuring that parts are produced quickly, consistently, and in high volumes, helping to streamline the supply chain.

By using injection molding, manufacturers can reduce lead times and maintain a steady flow of parts, making it easier for automakers to meet production targets without delays. This is especially important as companies work across borders and time zones to meet the needs of customers worldwide.

Impacting Innovation and Customization

Injection molding has become a driving force behind innovation in the automotive industry, offering manufacturers the ability to create highly customized parts and designs. The flexibility of this process allows for intricate shapes and features that were previously impossible or cost-prohibitive to produce.

Whether it’s a new type of interior trim or a custom-engineered part for enhanced performance, injection molding can accommodate unique designs with precision, making it easier for automotive companies to differentiate their vehicles and cater to specific consumer needs.

Beyond just customization, injection molding also supports innovation by enabling rapid prototyping and shorter development cycles. Manufacturers can quickly produce prototypes and make adjustments without the lengthy setup times required by traditional methods. This speeds up the innovation process, allowing for quicker testing and refinement of new designs.

Key Takeaway

The impact of injection mold makers in the automotive industry cannot be overstated. As automakers continue to strive for higher performance, better fuel efficiency, and cutting-edge designs, the expertise and capabilities of injection mold makers are essential to these advancements.

At Richfields Corporation, we understand the importance of precision, quality, and innovation in the automotive industry. With our advanced injection molding technology and years of experience, we are the ideal partner to help you achieve your manufacturing goals.

Contact us today to see how our services can drive your business forward and support your automotive production needs.