What are common food-grade plastic resins?

- Polyethylene Terephthalate (PET)

- Polypropylene (PP)

- High-Density Polyethylene (HDPE)

- Low-Density Polyethylene (LDPE)

- Polycarbonate (PC)

- Polystyrene (PS)

If you’re interested in creating your plastic food packaging, then it’s essential that you’re using materials that can come into contact with your food without any adverse side effects.

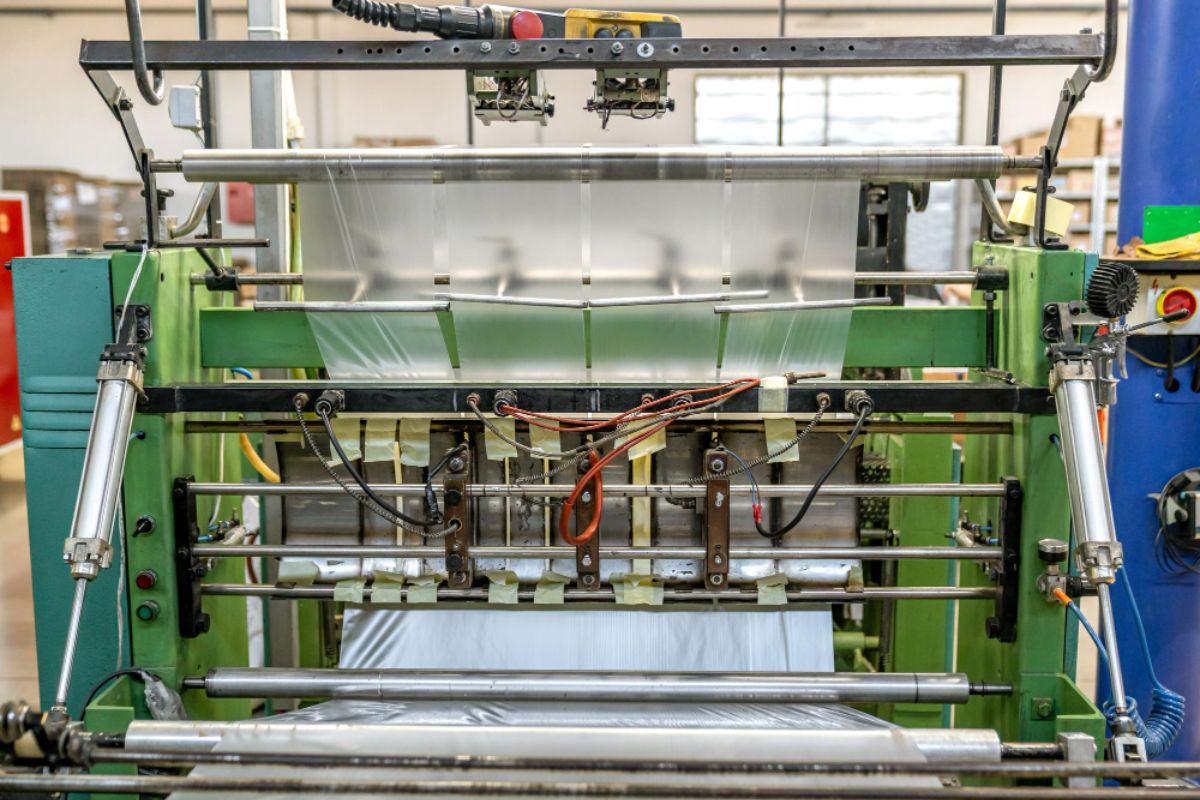

For plastic injection molding, those materials are called food-grade plastic resins. These are resins that are approved for contact with food by the Food and Drug Administration (FDA). They are also known as food contact substances (FCS).

To help you pick out the right resin, here is an overview of the different food-grade plastic resins you can use, and their recommended applications:

Polyethylene Terephthalate (PET)

Polyethylene Terephthalate, also called PET, is a resin that’s widely used for food packaging. It is one of the most commonly used plastics for this specific application. You can see them in liter soda bottles, salad dressing bottles, peanut butter jars, and just about any plastic food container that you can think of.

Of these uses, PET is mostly used to make single-serving drinking bottles, microwaveable plastic containers, take-out containers, and single-use food trays. The FDA has also allowed both virgin and recycled PET to be used for these purposes

The reason that it’s so widely used, even after recycling, is because PET has no negative health effects when it comes into contact with food. It is biologically inert, meaning it has no reaction whatsoever when ingested, handled with bare skin, or even inhaled. It’s also a stable resin, so it doesn’t degrade when exposed to food or beverages, it has excellent corrosion resistance, and repels most microorganisms.

Polypropylene (PP)

Polypropylene, also simply known as PP, is another widely used plastic in the food and beverage industry. You likely have some PP plastic food containers in your fridge or cupboards at this very moment! It’s often used to make reusable food storage containers, such as Tupperware. You can also find it in food containers and tubs, such as those used for ice cream and yogurt.

Like PET plastics, PP plastics are inert and stable plastics. So, they don’t present a health hazard to users, and it doesn’t react with liquids, acids, and bases — which makes them perfect for a variety of foods. Recycled PP plastics are also considered a food-safe material. It also has a high melting point, which makes it suitable for being reused and heated.

High-Density Polyethylene (HDPE)

HDPE is a common household food-safe plastic. You can find it in the juice and drink aisles in your groceries as the plastic bottles holding your favorite beverages. It is also often used for making the durable food buckets you often see in school cafeterias, food concessionaires, and restaurants.

HDPE resins are great for making food and drink packaging that needs to be highly corrosion resistant and absorbs very little moisture. Hence, it’s most often used for storing beverages. A bonus is that HDPE containers don’t leech coloring or chemicals into their contents, so they can stably hold beverages for a long time.

Low-Density Polyethylene (LDPE)

LDPE resin is similar to HDPE plastics but is known to be less rigid and durable. So, they’re popular for applications wherein the packaging needs to be more ductile — such as ketchup and mustard squeeze bottles, plastic wrap for veggie and meat products, six-pack rings, and the like.

LDPE, similar to HDPE plastics, features good chemical resistance, impact resistance, and wear resistance. And, they can hold food products for a long time without any harmful materials or chemicals seeping into the food. Likewise, this also helps prevent microorganisms from permeating or reproducing in the contained food or beverage.

Polycarbonate (PC)

Also called PC, it’s a food-safe plastic resin that’s often used to make beverage containers. Most common uses include water-cooler bottles, baby bottles, sippy cups, reusable water containers, and the like. It’s valued for its clear appearance and especially tough plastic.

In the past, PC resin was subject to heavy scrutinization, as many thought it was not food safe due to certain components — particularly BPA. This led to extensive testing which proved that the consumption of its BPA component was very low, and doing so did not result in any health risks.

Polystyrene (PS)

Polystyrene (PS) is a colorless, hard, and rigid plastic. It can be made into foam plastic, which most of us are familiar with, or cast into molds to create a solid shape. In its foam form, it’s a common material for disposable plastic cups, food trays, and fast food containers. In its solid form, it can be used to make food containers and lids, egg cartons, and hot cups.

It can be recycled, much like other food-grade plastic resins on this list. It is, in fact, recommended that plastic injection manufacturers do so, as PS takes an incredibly long time to biodegrade.

Key Takeaway

So, there you have it. These six materials are the most common food-grade plastic resins you can find in the food and beverage industry. Each one has its recommended use and advantages that you should keep in mind.

Interested in learning more, or need assistance with your plastic packaging project in the Philippines? Message Richfields today. We have years of experience catering to the food and beverage industry, and would be happy to help you!