What are the advantages of prototyping in manufacturing?

- Lower costs

- Better design

- Diagnose issues early on

- Get chances for funding

When it comes to prototyping, its advantages in manufacturing plastic products and other types of end-user goods are unmatched. It offers customers with low-cost options, better design, involvement, high accuracy, and ability to diagnose design issues early. Prototyping services in China as well as in other countries see to it that they prioritize on this step in the production process. This provides the client with not only an accurate picture of their preferred deliverable, but also a chance to test out their products and simulate its quality and effectiveness in various situations.

What is Prototyping?

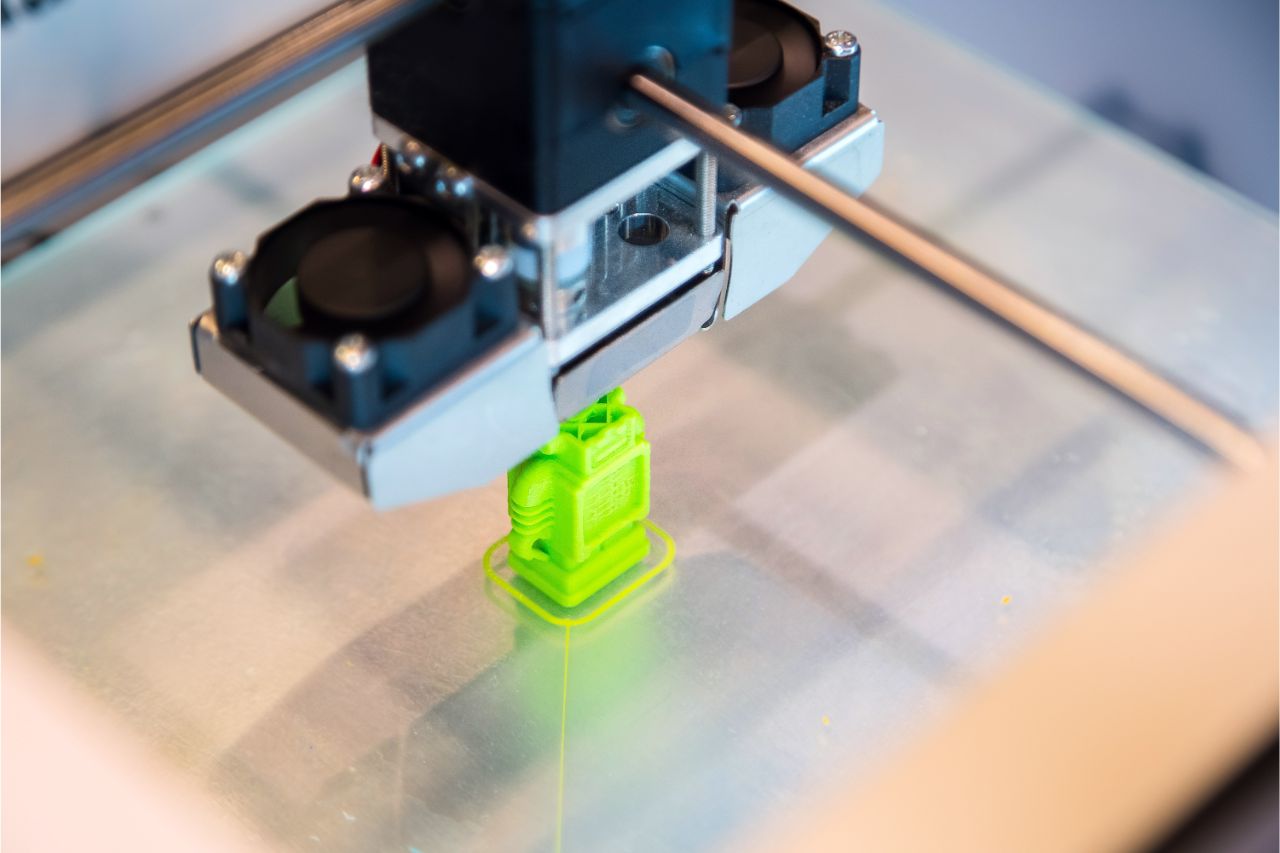

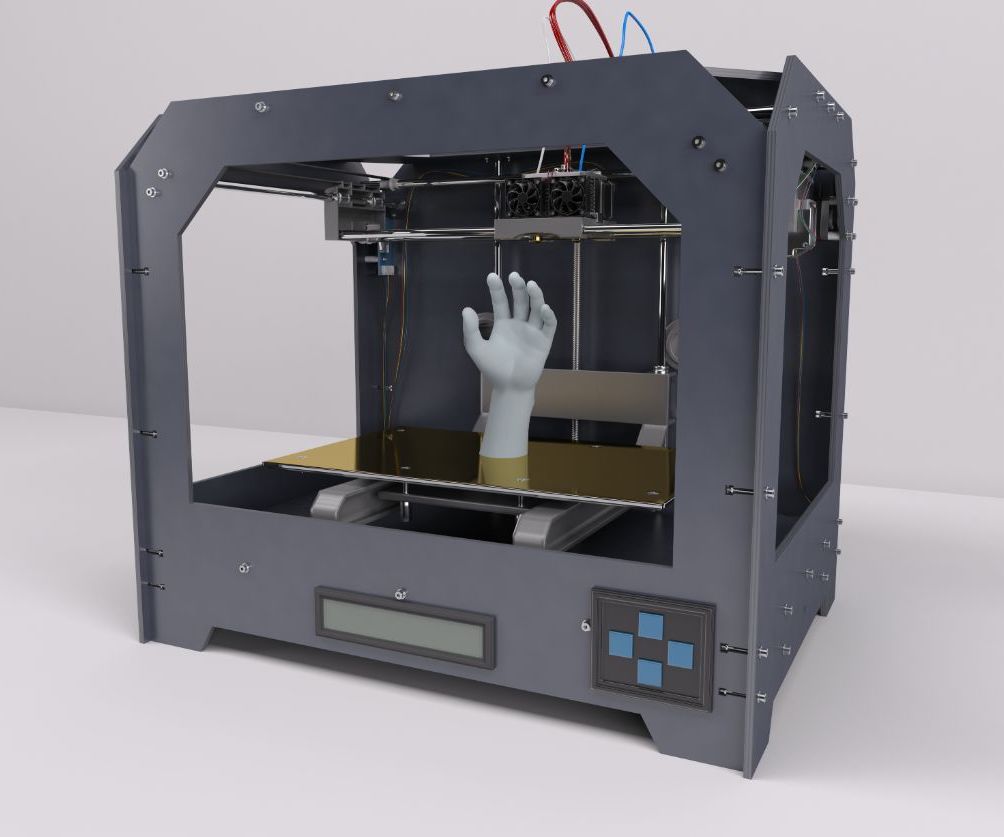

Prototyping is a facet of production where manufacturers try to create a model that is similar in design, appearance, quality, and function as the finished product. The idea of prototyping is to not fabricate the exact product, but only to get close to it for the purposes of quality assurance and testing.

For companies or individuals that want to introduce a plastic product in the market, injection mold prototyping is one of the most effective ways to go about it. It’s a non-capital-intensive option, which can help reduce manufacturing costs.

Furthermore, enlisting the services of a professional injection mold prototype can guarantee that you get reliable results that can help you decide on distributing the product to the wider market. Read on to learn more.

Lower Costs

One of the primary advantages of prototyping is that it helps you lower the cost of resources. In prototyping, you can figure out which materials, parts, or components don’t work before you decide on mass market production. Companies too often make the mistake of skipping this important production phase, because they assume that one-time testing is enough to determine the product quality. However, it shouldn’t be a habit.

When you don’t test out a product in the first place, you run the risk of financial losses in the long term. For example, issues with the quality can make consumers turn away from your product. This may eventually lead to lower sales and net losses, particularly when mass production is still ongoing.

To avoid this, you need to have an injection-molded prototype done. This is so that you can get it right the first time around. If there are any issues that weren’t covered during the testing phase, addressing them later is much less costly and more easily managed.

Better Design

If you’re not working with a team when it comes to product design, you may not necessarily make the best choices on the final outcome. Ultimately, you need to receive consultations and suggestions from other parties. Their input can help you improve the design of your product before distribution.

With this in mind, prototyping gives you the advantage of modifying the design of your initial model. Different prototyping tests can help you determine whether or not the design works. Let’s say you’re designing stackable plastic containers. Prototyping helps you figure out whether your design is fit for all kinds of situations. You can also figure out whether or not it has the best ergonomics for ease of use.

Likewise, you can also receive expert input from the prototyping company. They have all the tools and machinery to help you make alterations to come up with the most optimal design for any specific product.

Diagnose Issues Early On

As mentioned before, faults in the final product design can cause a number of financial problems. Aside from losing customers, you can also expect to spend exorbitant amounts on trying to fix issues. While you may have the resources and capabilities to do so, this is not a practical situation.

As much as possible, you want to be able to diagnose product defects during the prototyping stage. You wouldn’t want to “defraud” your investors and your customers by passing off a product as finished when it is in fact, riddled with errors that may even render it unusable.

Prototyping allows you to address these issues because you can freely assess which aspect of the model does not work. Even the subtlest of tweaks can determine the success of the finished good.

Get Chances For Funding

Prototypes are ideas and concepts that have been actualized. Sure, you may have the next big thing when it comes to your concept plastic product. But if you don’t have anything concrete, convincing investors and customers to fund you can be difficult.

On the business side of things, prototyping may also help you increase your chances of getting funding. Having a working prototype in hand allows you to exhibit your product and all of its features to your target audience. Patenting ideas is nearly impossible to do — keep this in mind before you decide to skip out on the prototyping aspect of your product.

Key Takeaway

Prototyping has advantages in manufacturing. It helps in the creation of better design, diagnosing problems as soon as possible, lowering costs, and increasing chances of investor funding.

Although prototyping is applicable in many industries, its importance shouldn’t be discounted when it comes to injection molded products. If you’re in need of prototyping services in China, Richfields plastics can provide you with all the critical equipment and machinery needed for your primary model. With their services, you can come up with the most optimal version of your intended design for your industry. Click here to get in touch with them!