Overview

- The decision between large-size plastic molding and traditional metal fabrication can significantly influence the manufacturing outcome of your product.

- It’s crucial to comprehend the distinct advantages and constraints of each method to identify the most suitable manufacturing solution tailored to your specific product requirements.

- Many companies favor large-size plastic molding because of its versatility, cost-efficiency, and capacity to efficiently manufacture intricate components.

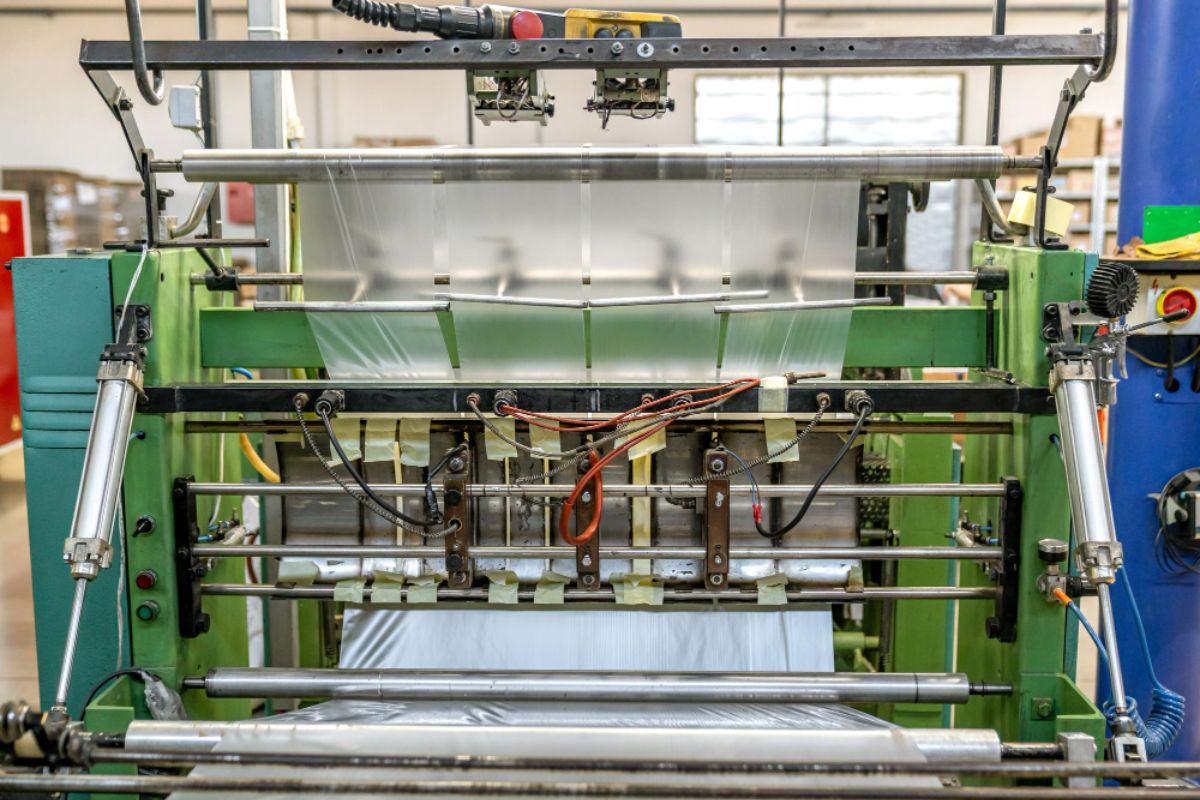

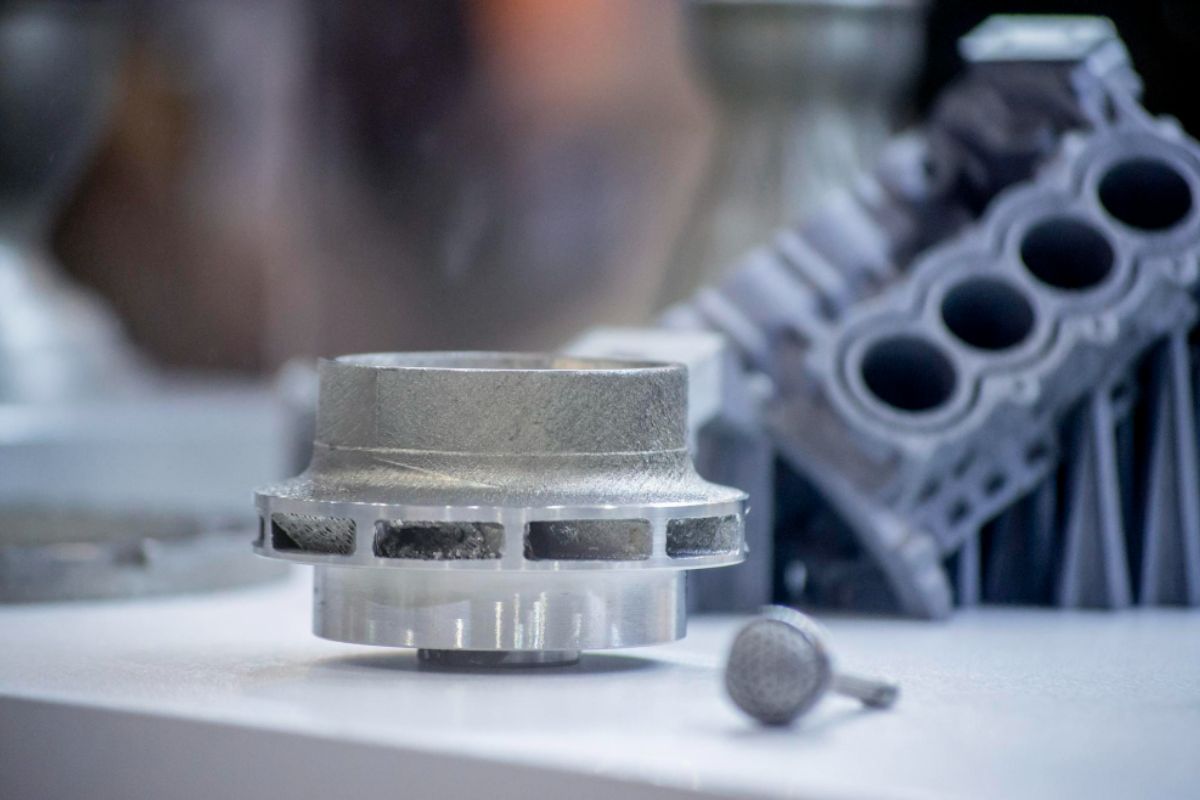

Large-size molding involves the creation of sizable components or products by shaping molten materials like plastics within a mold. It is commonly used in industries like automotive and aerospace. On the other hand, traditional metal fabrication encompasses techniques like cutting, bending, welding, and machining metal pieces to form structures or products, which is prevalent in machinery and architectural components.

In manufacturing, your choice between large-size plastic molding versus traditional metal fabrication can impact the outcome of your product. This article lets you find out the factors influencing the material choice, strength, and durability comparison, and why large-size plastic molding is preferred by many companies.

Factors Influencing Material Choice

Several factors contribute to material selection, which influences the outcome and performance of the final product. Here are some of these influential factors.

Product Functionality Requirements

One of the main considerations in material selection is the functionality requirements of the product. This includes factors like mechanical properties, thermal properties, electrical properties, and chemical resistance.

This ensures that the chosen material aligns with the intended functionality and performance criteria of the final product.

Cost Considerations

Plastic molding can often be more cost-effective than metal fabrication, especially for large-scale production runs.

Plastic materials tend to be less expensive than metals, and the molding process can be highly automated, which reduces labor costs.

Production Volume

Plastic molding is generally more efficient for high-volume production due to its ability to produce large quantities of parts quickly and consistently through injection molding.

Metal fabrication can be more suitable for low to medium-volume production, where tooling costs are less prohibitive, and the flexibility of metalworking processes allows for easier customization and adjustments.

Lead Time

Plastic molding processes often have shorter lead times compared to metal fabrication, particularly for high-volume production. The setup time for plastic molding is typically shorter, and once the molds are prepared, the production process can be highly automated and streamlined.

In comparison, metal fabrication processes may require more time for setup and machining operations.

Design Complexity

Plastic molding is well-suited for producing intricate shapes and complex geometries—with the flexibility of mold design and the ability to replicate detailed features consistently.

Metal fabrication processes like machining and welding can also accommodate complex designs but may require more post-processing and finishing to achieve the desired results.

Material Properties

Plastic materials offer benefits like corrosion resistance, electrical insulation, and the ability to reduce part weight.

On the other hand, metals provide superior mechanical strength, thermal conductivity, and durability in demanding environments.

Strength and Durability Comparison

The comparison between strength and durability in large-size plastic molding versus traditional metal fabrication serves as an important point of consideration. Here are their comparisons.

Material Strength

Plastic materials like carbon fiber reinforced polymers can exhibit comparable strength to steel but with significantly lower weight, making them advantageous in weight-sensitive applications such as aerospace or automotive components.

While metals are generally known for their high strength, certain plastic materials can rival or even surpass metals in specific applications.

Impact Resistance

Plastics excel in impact resistance, which disperses energy upon impact and makes them fit for applications like automotive bumpers and protective gear.

Metals may lack the impact resistance of plastics, but alloys and fabrication techniques can enhance their ability to withstand impacts.

Fatigue Resistance

Metals generally outperform plastics in terms of fatigue resistance that endure repeated stress cycles without degradation.

Plastics may degrade over time when subjected to cyclic loading. However, it depends on various factors like material composition, design, and operating conditions.

Corrosion Resistance

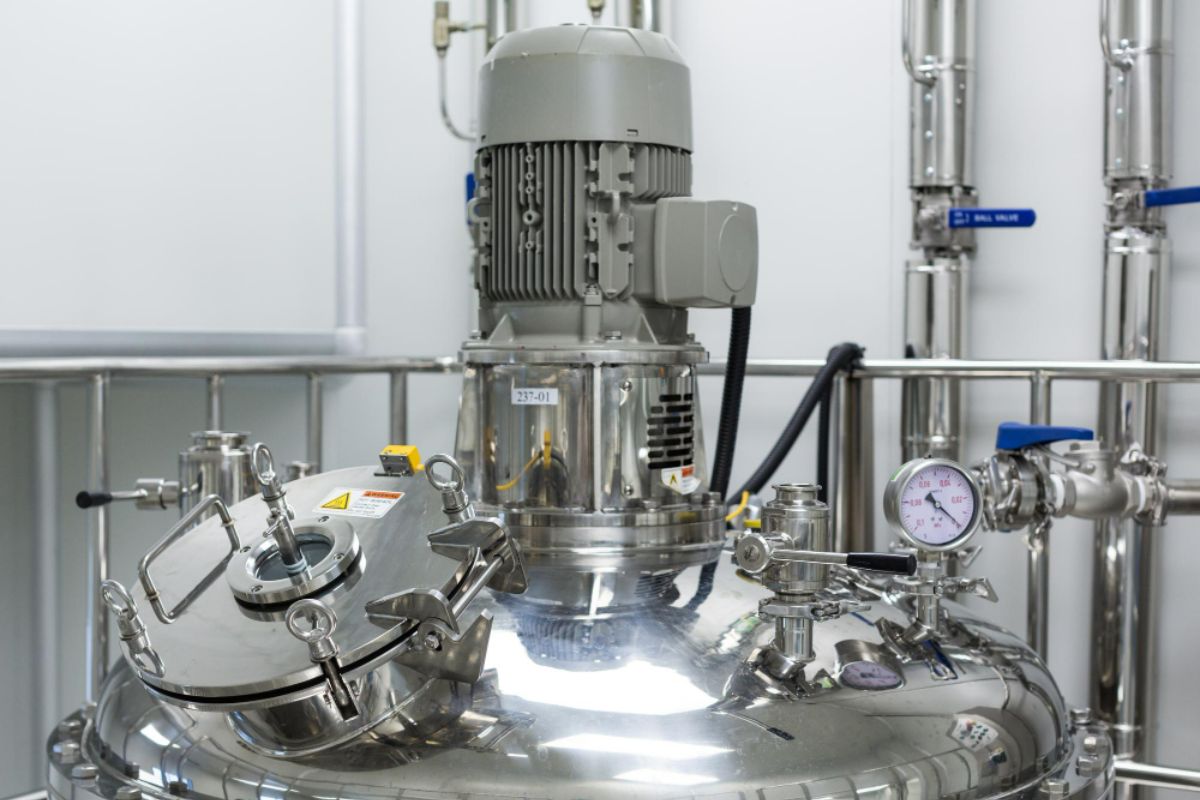

Plastics have a natural advantage when it comes to corrosion resistance when exposed to moisture, chemicals, or harsh environments.

Metals like stainless steel and aluminum can also offer excellent corrosion resistance with the use of protective coatings and alloying elements.

Why is Large-Size Plastic Molding Preferred by Many Companies?

Plastic molding techniques like injection molding, rotational molding, and blow molding offer the flexibility to create intricate shapes and large-size parts with ease, unlike traditional metal fabrication which struggles for an efficient fabrication of large-size components with intricate features. This versatility of plastic molding allows companies to realize complex designs and optimize product functionality.

It also proves more cost-effective for high-volume production since it requires lower material costs and shorter production cycles compared to metal fabrication. Plastics exhibit excellent corrosion resistance and can withstand harsh environmental conditions that makes them applicable to various industries like automotive, aerospace, consumer goods, and construction.

Key Takeaway

It’s important to recognize the distinct advantages of large-size plastic molding versus traditional metal fabrication. Large-part plastic molding offers unparalleled versatility in crafting intricate shapes and lightweight components, surpassing the limitations of traditional metal fabrication.

Are you in search of a large-size plastic mold maker for your product? Richfields Corporation stands as a reputable plastic mold manufacturer. Over the years, we’ve earned recognition as a leading provider of plastic mold-making services that offers top-notch customer service to clients in China and the U.S.A. Reach out to us today to learn more about our services.