What are the differences between injection molding and compression molding?

- Process

- Production capacity

- Precision

- Complexity of models

- Lead time length

There are many different methods involved in plastic production. When comparing injection molding vs. compression molding, you need to understand which method is more efficient. You should also know which can be suitable for a wider range of plastic products or prototypes.

Both methods involve the use of heat and pressure to shape plastic raw materials into the desired form. However, there are a number of major differences between the two that can make the other process more advantageous than the other. Read on to learn more.

Process

The process for compression molding seems simple because of the relatively few components involved, namely, the raw polymer, upper plug, and a heated mold. Here’s a step by step process of how it’s done:

- As the name suggests, compression molding starts off with a raw plastic material that is heated and compressed.

- The high-temperature material is then transferred into an open tooling die that has a particular cross section. This primary step only focuses on the lower half of the material.

- To fully shape the plastic, an upper plug is pressed onto the plastic compound, ensuring that the specimen is evenly distributed throughout the mold cavity.

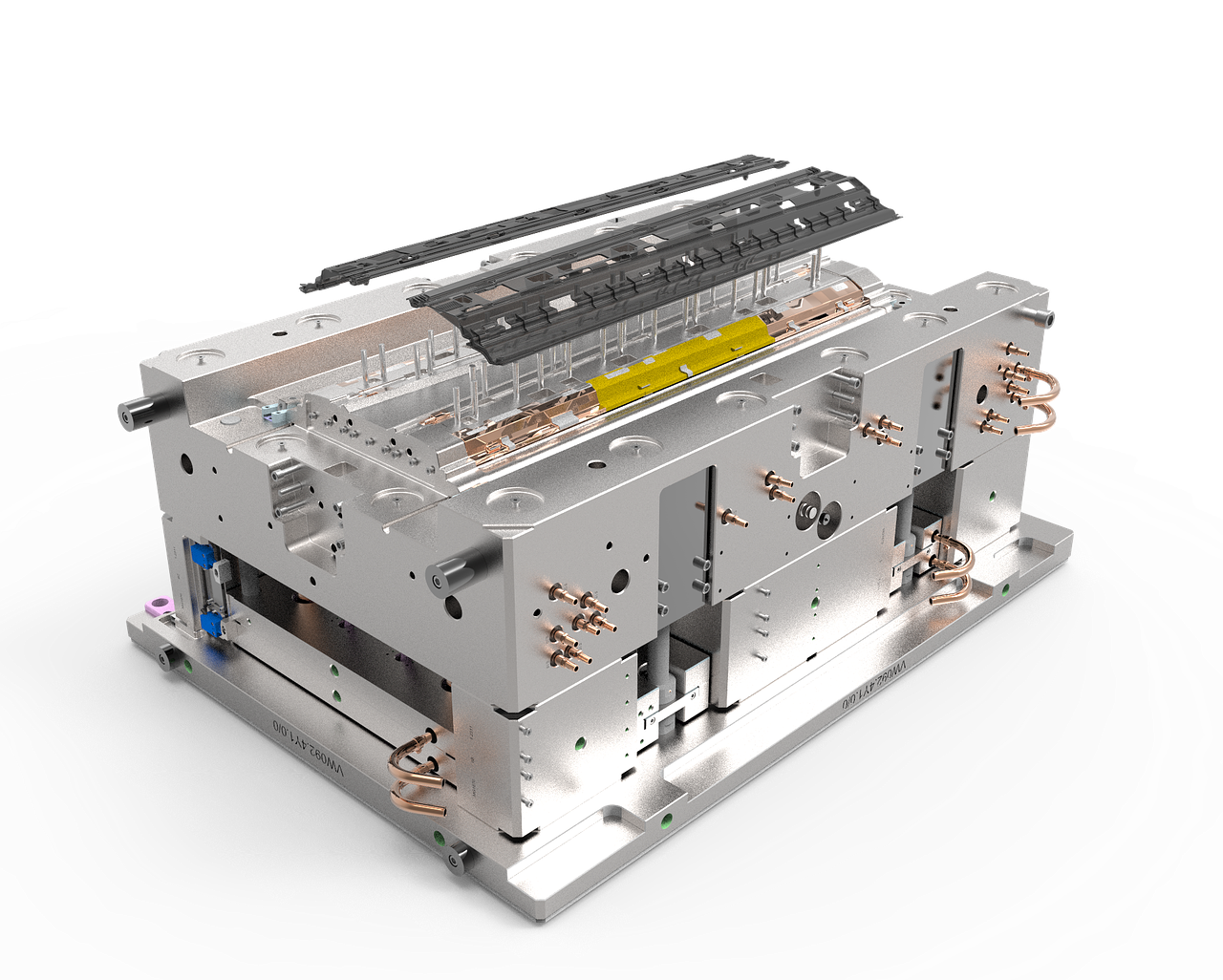

On the other hand, injection molding requires the presence of feed hoppers, heaters, an injection unit, clamping unit, hydraulic cylinders, and more. Here’s how it works:

- Raw materials like acrylic, nylon, polystyrene, or polypropylene are first transformed into machinable resins or pellets that are fed into the hopper.

- The materials are consistently heated and then carefully transferred into the mold or workpiece where they’re shaped.

- The clamping unit secures the other half of the mold into place. Upon release, the resulting end-product is cooled before being discharged from the die.

Production Capacity

In terms of production capacity, compression molding is ideal for high-volume production, while injection molding is ideal for low-volume production. For applications that don’t necessarily rely on multiple prototypes of the same type, injection molding would be preferred.

For example, if you’re trying to meet a deadline on coming up with several prototypes for a new set of plastic dining sets, then you should definitely go with compression molding. In this way, you’ll be able to conduct quality assurance inspections on each molded product in no time at all. Meanwhile, if you want to be more practical with your options, it’s best to have your prototypes fabricated through injection molding. This gives you a low-cost method of identifying what kind of tweaks or alterations are required for the product before full production takes place.

Nevertheless, both injection and compression molding can be suitable for a variety of production levels, depending on the kind of raw material used.

Precision

The best thing about injection molding is that the molds that are ejected from the machine do not require further post-processing due to the precision of dimensions. The die used in injection molding can be made of durable materials like steel which have a high strength and hardenability rating. This means that they are less prone to deformations that may affect the shape of the resulting mold, especially after prolonged usage.

Unlike compression molding, the machine operator can easily control the level of heat and pressure that are applied throughout the molding process. This makes it easier for them to produce prototypes that have a more consistent shape and thereby require less fine-tuning.

Complexity of Models

The injection molding technique is more capable of producing far more complex models and designs compared to compression molding. With this in mind, it’s more convenient to experiment with design ideas with the help of the injection molding process. More than that, injection molding also offers you an opportunity to test out the resulting product and see if it can effectively hold up in the actual setting.

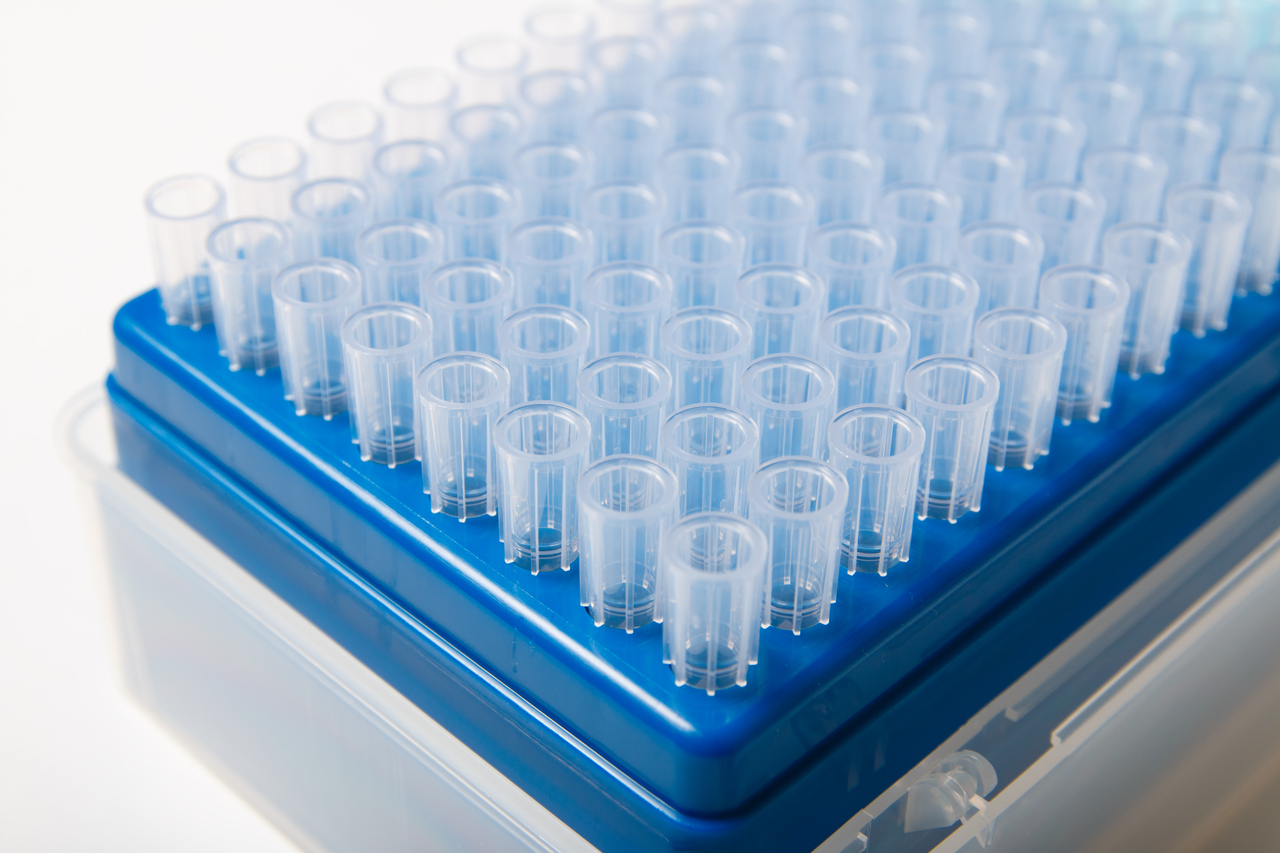

Some of the most common products that you may encounter as a result of the compression molding process are bottle caps, rounded inserts, kitchenware, electrical housing, and the like. The main driver behind the simplicity of designs across compression-molded products is the minimally-sophisticated components and procedures.

Meanwhile, products like sports equipment, protective gear, plastic containers, headphones, and other plastic replacement parts are all made possible through injection molding.

Lead Time Length

Though it was said earlier that compression molding is more suited for use in high-volume production, their lead times are much longer compared to injection molding. Lead time is simply defined as the length of the period it takes between the beginning and the end of the process.

Since the production process for injection molding is shorter, it is far more reliable to clients that need to test out a given prototype in a single day. They don’t have to wait long before they even get to assess whether the product can be fit for use.

On the end of the manufacturers, the short lead time allows them to accommodate other core aspects of their operation. They can attend to different machines at any given time and increase the overall productivity levels of the facility.

Key Takeaway

There has been a long-standing discussion on injection molding vs compression molding to find out which process is truly more efficient.

As said before, compression molding involves simpler machines, meaning they’re capable of producing a range of simple plastic products. With the complexity of the injection molding technique, on the other hand, it is able to perform a wide variety of functions to create products that are used by many industries. Choosing between the two methods is all about understanding which one is able to meet your needs better.

Want to learn more about the injection molding process? The team from Richfields can help you out. Click here to get in touch with them.