What are the advantages and disadvantages of plastic injection molding and vacuum forming?

- Both Form Plastic Using Different Methods

- Vacuum Forming Has Its Drawbacks

- Plastic Injection Molding Is The Optimal Plastic Forming Method

There are two types of plastic forming methods that are popular among manufacturers. Each method is designed to create results that are suitable for large production and small production runs. When thinking about injection molding versus vacuum forming, you can deduce a lot of differences for each process. To know which plastic forming method is for you, here are the key similarities and differences of each.

Both Form Plastic Using Different Methods

It’s no secret that there are many ways to manufacture plastic parts. Two of the most popular are plastic injection molding and vacuum forming. Both of these offer advantages depending on how you apply each method. Here are the definitions of each.

Vacuum forming is an economical thermoforming process that makes use of a vacuum form to create the product. The thermoplastic material chosen is heated in an oven. This material is then transferred and set on a mold. While the material is still hot, a vacuum will pull the air out of the mold to help the sheet form the shape. The thermoplastic material will cool in the form of the mold which can be removed and trimmed to complete the product.

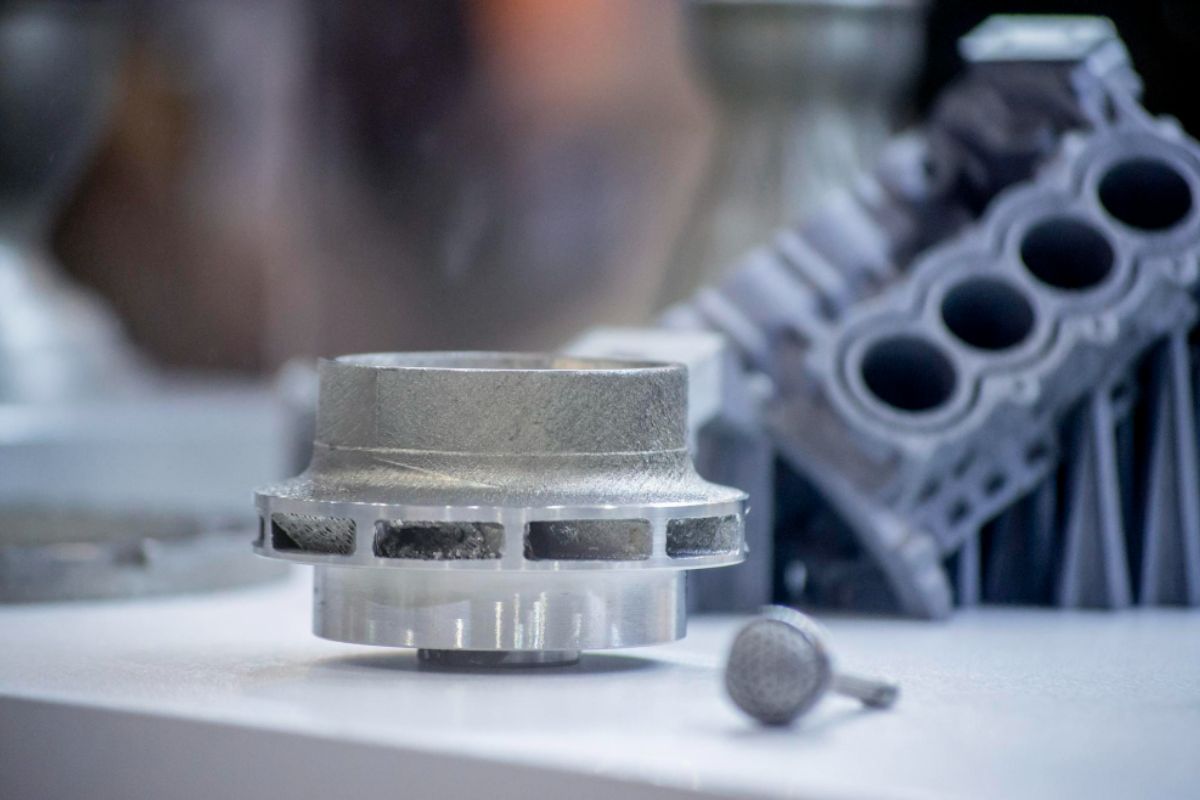

Plastic injection molding is the most common way to create products. Plastic injection molded objects can be found everywhere, including in your car and kitchen. This plastic forming method involves melting the plastic of choice and injecting it using high pressure between a mold cavity and the mold core. The plastic is cooled, which facilitates solidification. After the cooling process, the cavity opens and the object is ejected.

Vacuum Forming Has Its Drawbacks

Image Source: Flickr.com

Even if you find that you can easily create prototypes and large parts in a short amount of time, vacuum forming still has some drawbacks you need to take note of. Lower start-up costs introduce economic patterns and molds but it may be difficult to get a consistent product. Consistent wall thickness all around the mold is not easily achievable and can take a few tries to get it right. If you have a mold with deep crevices and intricate parts, you will find this challenge a bit daunting. If you don’t keep a consistent workflow and clean station, some parts will exhibit defects and dirt from the mold. It will easily transfer to your finished product and to multiple parts if not properly addressed.

Vacuum forming also tends to have a higher per-piece cost. This may not be suitable if you’re competing with other processes that can produce higher quantities through computerization. Other plastic forming methods can allow you to use different resins and plastics during the formation process. With vacuum forming, you need to stick with one material at a time to ensure a consistent output. Finishing your vacuum formed object also requires more labor as it needs to be cut and trimmed into the right shape. This will cost more than a product formed using plastic injection molding.

Plastic Injection Molding Is The Optimal Plastic Forming Method

Initially, you will be greeted with higher start-up costs with injection molding. This requires engineering expertise and a bit of time to fully master. There are longer time frames to manufacture a mold due to the multiple parts being used. But the initial cost investment and time investment is worth it. Injection molding has multiple benefits you can enjoy in the long run such as high production rates. A mold and mold cavity can be used to rapidly create accurate and uniform products in a short amount of time. You can even choose to add extra inserts and fillers in the mold to increase the quality and strength of the shape.

For intricate details, you can create different shapes at ease due to the uniform nature of the mold and the molten plastic. The molten plastic coats every corner of the mold to ensure that all parts are achieved once cooled and ejected. Due to the smoothness of the mold itself, it can be easy to achieve a smooth and finished look without the extra labor. If you’re wondering about waste and scraps, you need not worry about creating too much. These scraps can be remelted and reused to ensure all the plastic material you have on hand is used for production. With the use of computer technology, fully automated processes are possible thus reducing labor costs.

Key Takeaway

To conclude the argument of injection molding versus vacuum forming, it’s easy to see that plastic injection molding has more advantages. Both have their respective strengths and weaknesses which can appeal to the production level you desire. However, if you want something that is consistent in quality, quantity, and speed, plastic injection molding is an excellent choice. It’s a great investment to make if you’re looking to create products that are consistent in quality but without the hefty unit cost compared to other methods.