April 23, 2025

Unlocking China’s Mold Mastery: Finding Your Ideal Partner

Overview

- Businesses in industries like OEM manufacturing, product design, global trade, industrial production, and automotive rely on high-quality plastic components and can benefit from partnering with expert injection mold makers.

- Experienced mold makers ensure precision, durability, and scalability, helping businesses streamline production while maintaining quality and reducing costs.

- From automotive parts and consumer goods to medical devices and electronics, plastic molding supports various industries with reliable, high-volume manufacturing solutions.

Injection mold makers in China have become a preferred choice for companies worldwide due to their expertise, cost-efficiency, and ability to handle large-scale production. However, how do you know if your business needs one?

In this article, we’ll explore the different industries and professionals that can benefit from partnering with injection mold makers, and how these partnerships can streamline production, reduce costs, and enhance product quality.

OEMs are responsible for producing high-quality components and finished products for various industries, from automotive and electronics to medical and consumer goods. Many of these products require durable, precisely engineered plastic parts, making high-quality molds essential for their production.

By partnering with an experienced mold maker, OEMs can ensure that their plastic components meet strict quality standards while keeping production efficient and cost-effective. Additionally, working with a reliable mold supplier enables them to scale production smoothly and bring new products to market faster.

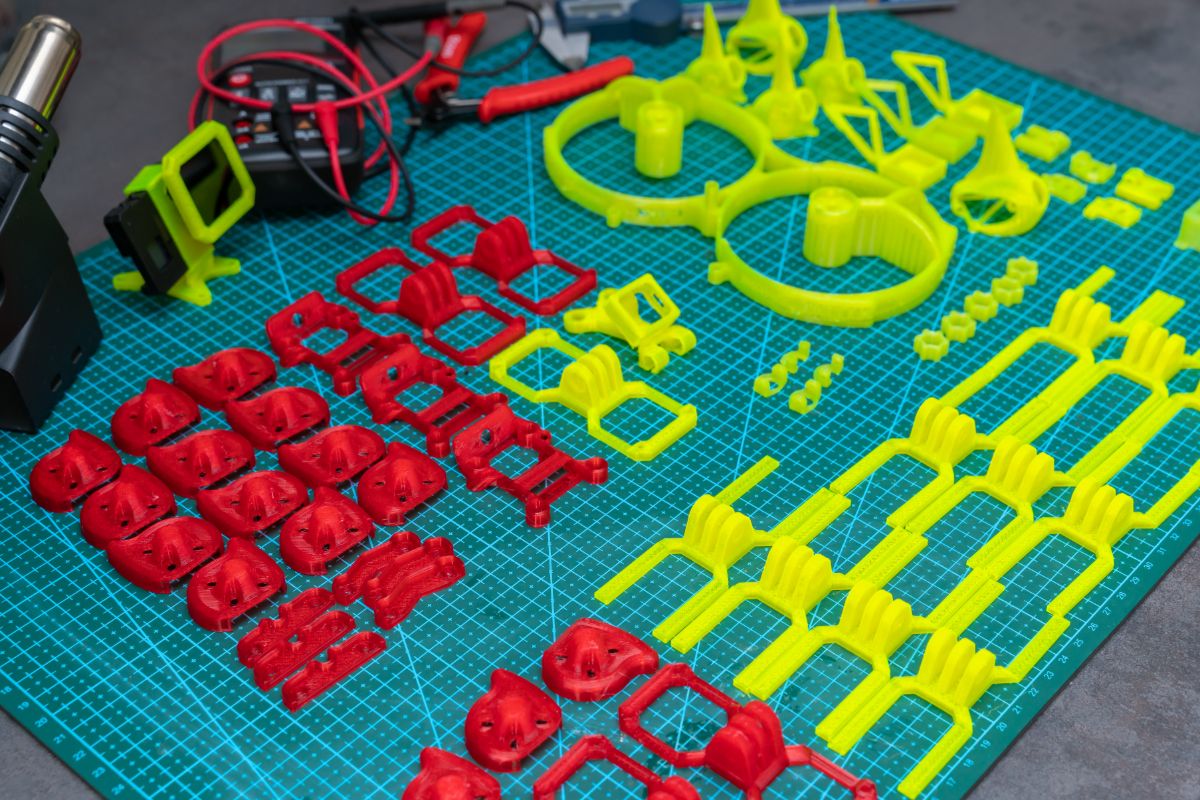

Designers and product developers play a crucial role in bringing a new product to life through careful planning, precise engineering, and efficient manufacturing. However, turning these ideas into high-quality, mass-producible plastic parts requires expertise in mold design and production.

With an experienced mold maker, designers can refine their product designs for manufacturability, ensuring that parts are not only visually appealing but also structurally sound and cost-efficient to produce.

This will also allow design optimizations, such as reducing material waste, improving durability, and streamlining the production process. This partnership helps designers and developers bring their concepts to market faster while maintaining high standards for quality and precision.

Exporters and importers serve as key players in global trade, facilitating the movement of goods between manufacturers and buyers across different regions. They connect businesses with reliable suppliers, ensuring that high-quality products reach international markets efficiently.

In industries that rely on plastic components—such as automotive, electronics, and consumer goods—exporters and importers must work closely with trusted manufacturing partners to meet demand.

Injection mold makers play a crucial role in this supply chain by providing high-precision plastic parts that exporters and importers distribute. By partnering with a skilled mold maker, they can ensure consistent product quality, competitive pricing, and compliance with international standards.

This collaboration allows exporters and importers to confidently supply businesses with durable, well-crafted plastic products, enhancing their competitiveness in the global market.

Manufacturers and producers are at the heart of industrial production, transforming raw materials into finished goods across various industries, from consumer electronics to medical devices.

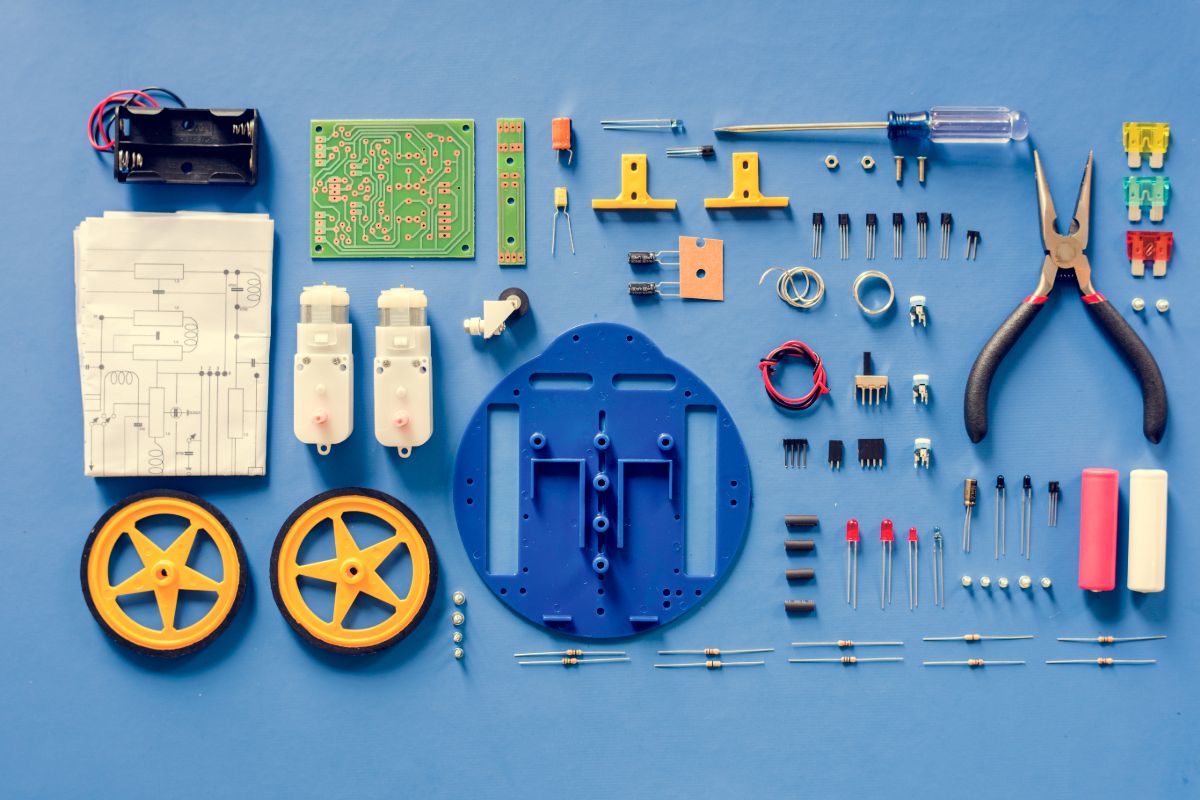

These businesses rely on efficient, high-quality production methods to maintain competitive pricing and meet customer demands. Plastic components, in particular, are essential in modern manufacturing due to their durability, versatility, and cost-effectiveness.

Injection mold makers support manufacturers by providing precision-engineered molds that ensure consistent, high-volume production of plastic parts. Additionally, mold makers offer expertise in material selection, mold design, and process optimization, helping manufacturers create parts that are not only functional but also cost-efficient.

The automotive industry is one of the largest consumers of plastic components, with modern vehicles relying on high-quality molded parts for both functional and aesthetic purposes.

From interior trims and dashboards to under-the-hood components, plastic offers durability, lightweight advantages, and cost-efficiency—key factors in vehicle manufacturing. To keep up with demand, automakers need precise, high-quality molds that can produce these parts consistently and in large volumes.

Injection mold makers play a crucial role in this process by designing and manufacturing the molds used to create automotive plastic components. Their expertise ensures that each part meets strict industry standards for strength, precision, and durability.

Injection mold makers in China play a crucial role in various industries, providing cost-effective, high-quality solutions for businesses needing precision-molded plastic components. Whether you are an OEM, designer, importer, manufacturer, or part of the automotive industry, partnering with the right mold maker can enhance production efficiency, reduce costs, and ensure product consistency.

At Richfields, we specialize in delivering top-tier injection molding services tailored to your needs. With our expertise, advanced technology, and commitment to quality, we are the ideal partner to help you achieve your manufacturing goals.

Contact us today to learn how we can support your production requirements and drive your business forward.