Latest Blogs

Why Size and Capacity Matter in Plastic Injection Molding Operations

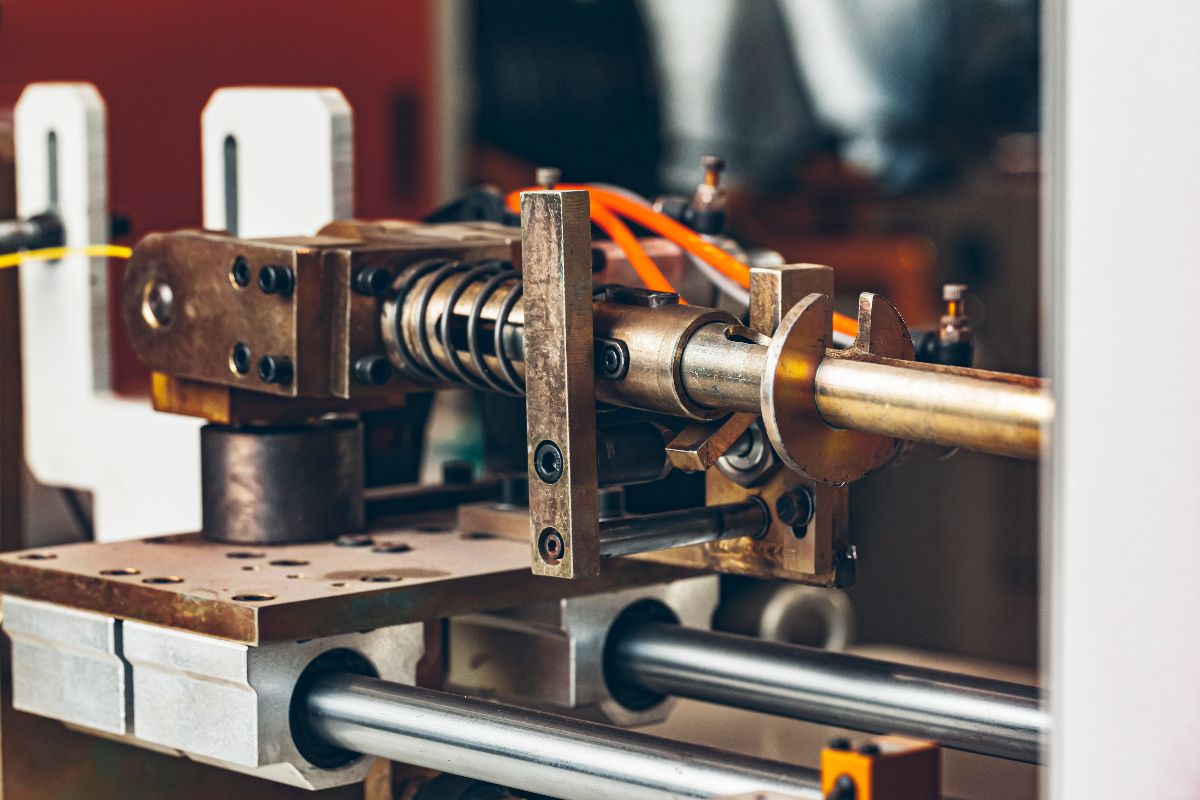

Overview Selecting the right injection molding machine size is vital to prevent defects such as flashing, warping, or incomplete fills. Proper tonnage and shot volume ensure part consistency and protect molds from stress. Richfields specializes in providing tailored presses worldwide that precisely match project requirements, securing quality production and cost efficiency with expert machine sizing […]

Read more

Common Large-Part Design Mistakes That Complicate Manufacturing

What are the common large-part design mistakes that complicate manufacturing? Ignoring manufacturing process limitations Over-specifying tolerances Poor material selection Inconsistent wall thickness Neglecting draft angles Covercomplicating the design Using non-standard components Overview Large-part injection molding often fails when designs ignore limitations involved in the processing. To avoid this, early collaboration is the best way to […]

Read more

Understanding the Scale and Capabilities of Large Plastic Injection Molding

Overview Large plastic injection molding uses high-tonnage machines to mold large, thick, and complex parts with precision and consistency. The procedure supports designs that require significant clamping force, shot volume, and physical mold size, ensuring defect-free, structurally sound components. Richfields is a leading provider, offering advanced machinery and technology to deliver high-quality large plastic injection […]

Read more

How to Expand Product Line with a Trusted Injection Molding Partner

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read moreOther Blogs

How Richfields Handles Complex Molding Projects for Global Clients

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more

Tips for Successful Customized Large Injection Molding Projects

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more

Why Large Injection Molding Works for Plastic Display Racks

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more

How to Cut Costs in Customized Large Injection Molding Projects

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more

Most Common Manufacturing Methods for Large-Scale Plastic Products

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more

Can You Use Plastic Products in Automotives?

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more

How Large Plastic Injection Molding Creates Plastic Chairs

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more

7 Consumer Products That Use Customized Large Injection Molding

Overview Expanding product lines with new SKUs involves overcoming design and manufacturability challenges that often cause costly delays. Careful planning, partner evaluation, and thorough vetting are essential to ensure scalable, high-quality production. Richfields offers expert injection molding support, early engineering input, and advanced tooling to speed up development and deliver precise, reliable results worldwide. Expanding […]

Read more