What are the things to remember about mold making requirements for US clients?

- Understanding client specifications

- Compliance with regulatory standards

- Material selection and quality

- Precision and dimensional accuracy

- Time and cost considerations

- Communication and documentation

- Testing and validation

Overview

Mold making for US clients requires a deep understanding of their specific requirements. This comprehensive guide covers key considerations, regulations, and best practices for successful mold making partnerships in the USA.

Understanding client specifications is vital, necessitating effective communication and alignment with their needs.

Compliance with regulatory standards, such as FDA regulations for medical devices and OSHA standards for workplace safety, is crucial.

Material selection and quality play a significant role

Precision and dimensional accuracy achieved through advanced technology.Time and cost optimization, clear communication, thorough documentation, testing and validation, and intellectual property protection are additional essential aspects to consider.

Mold making is an essential process in various industries, including manufacturing, automotive, consumer goods, and many more. When it comes to serving clients in the United States, it’s crucial to understand the specific requirements to ensure successful outcomes and seamless collaboration.

This article will provide a comprehensive guide to mold making requirements for US clients, covering key considerations, regulations, and best practices. By the end of this article, you will gain a deeper understanding of what it takes to partner with a full-service injection molding company in the USA.

Understanding Client Specifications

Before diving into mold making, it is essential to invest time and effort in fully understanding the specifications and requirements outlined by your US clients. Effective communication plays a crucial role in this process, as it enables a seamless alignment between your manufacturing capabilities and the needs of your clients.

Pay close attention to factors such as material specifications, dimensional tolerances, surface finishes, and any specific certifications or standards required. You should also consider small-scale production for US-based businesses, offering advantages such as flexibility, cost-effectiveness, and tailored solutions. Always remember how important it is to collaborate closely with clients and maintain open communication for successful outcomes.

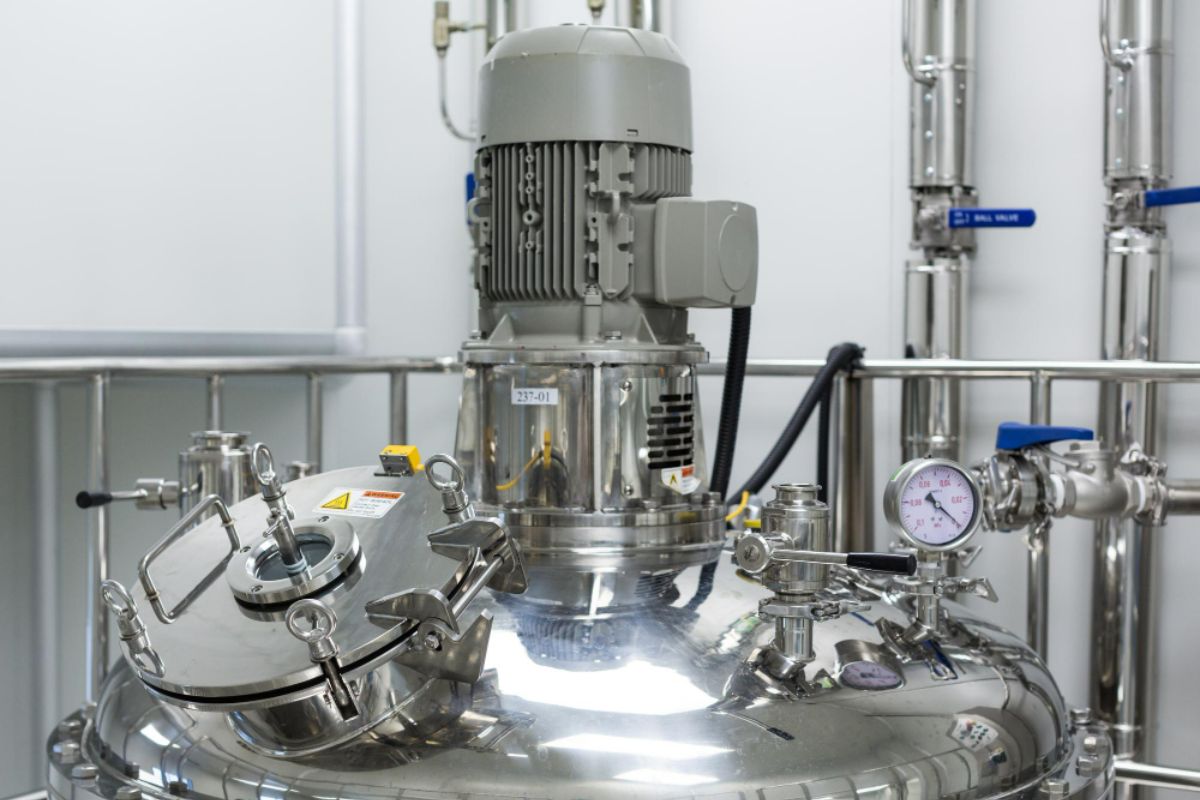

Compliance with Regulatory Standards

The United States has established rigorous guidelines in various industries for mold making, such as the FDA regulations for medical devices and the OSHA standards for workplace safety. Familiarize yourself with these regulations to ensure that your mold manufacturing processes meet the requirements. Adhering to these not only fulfills legal obligations but also demonstrates your commitment to producing high-quality and safe molds.

For example, the FDA guidelines outline the requirements for manufacturing medical devices, covering aspects such as material selection, cleanliness, and sterility. Adhering to these guidelines is essential when producing molds for medical devices intended for the US market.

Similarly, complying with OSHA regulations ensures a safe working environment for employees in mold-making facilities. You need to implement proper safety protocols, provide necessary training, and ensure the use of appropriate personal protective equipment (PPE) to meet OSHA requirements.

As important as it is to follow these standards, it’s equally important to stay updated on any changes or updates to these regulations to ensure ongoing compliance.

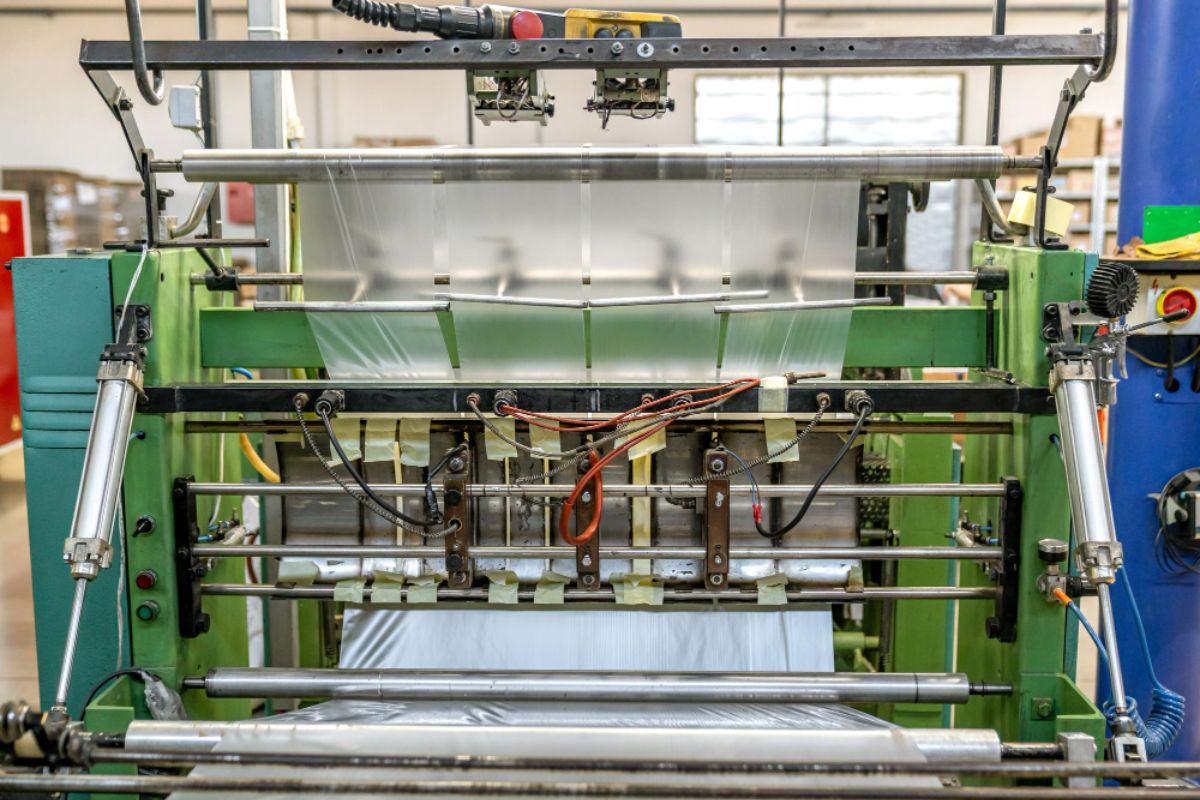

Material Selection and Quality

US clients often have specific material preferences based on factors such as product functionality, durability, and environmental considerations. Work closely with your clients to identify the appropriate material for their projects. Ensure that the materials you use meet industry standards and are of high quality to guarantee the longevity and performance of the molds.

For a more in-depth understanding of plastic mold tooling requirements in the US, we have created a separate article dedicated to providing you with additional insights and information.

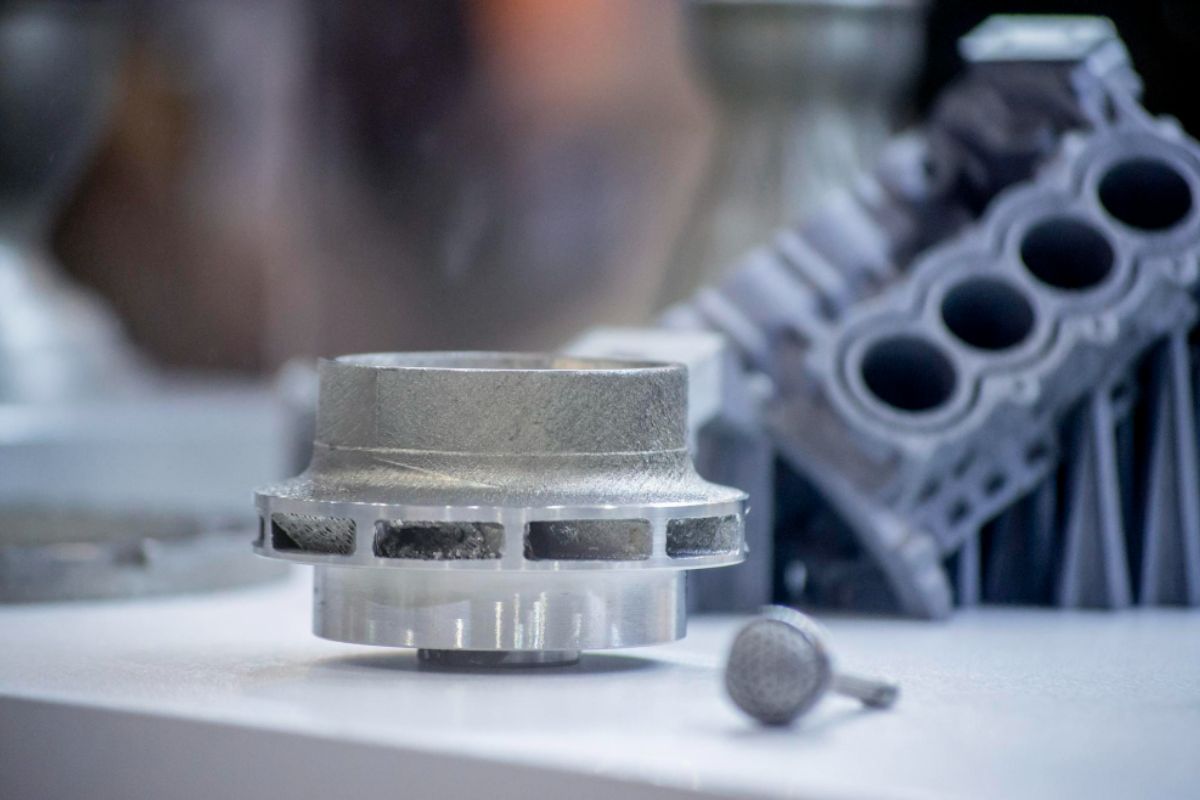

Precision and Dimensional Accuracy

Meeting the expectations of US clients in mold making requires a focus on high-quality molds that can consistently produce parts with precise dimensions and tight tolerances. It is essential to ensure that your manufacturing processes and equipment are capable of achieving the required level of precision.

To enhance precision and accuracy in mold making, companies in the US are increasingly embracing advances in technology. One such advancement is the utilization of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems.

CAD software enables the creation of detailed 3D models of the mold, allowing for precise visualization and analysis of the design before production. CAM systems, on the other hand, facilitate the translation of the CAD model into machine instructions, streamlining the manufacturing process and ensuring the accurate execution of the design.

By leveraging these advances in mold-making technology, US-based companies can stay competitive in the market by delivering molds that meet the high standards and expectations of their clients.

Time and Cost Considerations

Ensuring timely delivery and cost efficiency is important when working with US clients, as well as with any clients. It is essential to optimize your mold-making processes to meet agreed-upon timelines and budgetary constraints. Embracing lean manufacturing principles can greatly enhance your operations by streamlining workflows, reducing waste, and improving overall efficiency.

Communication and Documentation

Promptly addressing queries or concerns helps build trust and fosters a positive working relationship. Effective communication ensures that both parties are aligned on project requirements, timelines, and expectations.

This includes documenting all discussions, specifications, design changes, and approvals. Maintaining comprehensive records establishes a clear trail of decisions and actions taken during the project. These records serve as a valuable reference for future projects, allowing you to leverage past experiences and insights for improved efficiency and accuracy.

Furthermore, in the event of any disagreements or misunderstandings, having detailed records enables you to refer back to specific discussions or agreements. This helps in resolving conflicts, clarifying intentions, and finding mutually beneficial solutions.

Testing and Validation

Rigorous testing should be conducted to verify the performance, dimensional accuracy and durability of the molds. This may include functional tests to assess how the mold performs in producing parts, dimensional inspections to ensure precise replication of the desired specifications, and durability tests to evaluate the mold’s ability to withstand repeated use without degradation.

It is important to involve your US clients in the validation process. This collaborative approach allows them to provide valuable feedback and insights based on their specific application and industry requirements. The importance of this is you can make any necessary adjustments or improvements to the molds before proceeding to full-scale production. This iterative process helps to ensure that the final molds meet the desired standards and expectations.

Intellectual Property Protection

Protecting intellectual property is of utmost importance in mold making projects. US clients value their designs, molds, and proprietary information. Implement robust measures to safeguard their intellectual property rights. This includes establishing non-disclosure agreements (NDAs) and maintaining strict confidentiality throughout the project. Respect your client’s intellectual property rights and avoid any unauthorized use or disclosure.

Key Takeaway

We hope this guide to mold making requirements for US clients helps shed some light on the essential things you need to know, Successfully meeting all these requirements requires a combination of technical expertise, effective communication, and compliance with regulatory standards. Understanding and putting action on these specifications can deliver high-quality molds that meet or exceed your client’s expectations.

Explore large part injection molding with Richfields! As a trusted one-stop service provider, we offer high-quality injection mold-making and injection molding solutions for various industries worldwide. Whether you need large part molding for automotive components, electronics, sports equipment, or household products, our experienced team and state-of-the-art facilities ensure precise and durable results.

Don’t hesitate to reach out and discover how Richfields can meet your large-part injection molding needs.