What are the latest technological advances in mold-making for companies in the USA?

- 3D printing

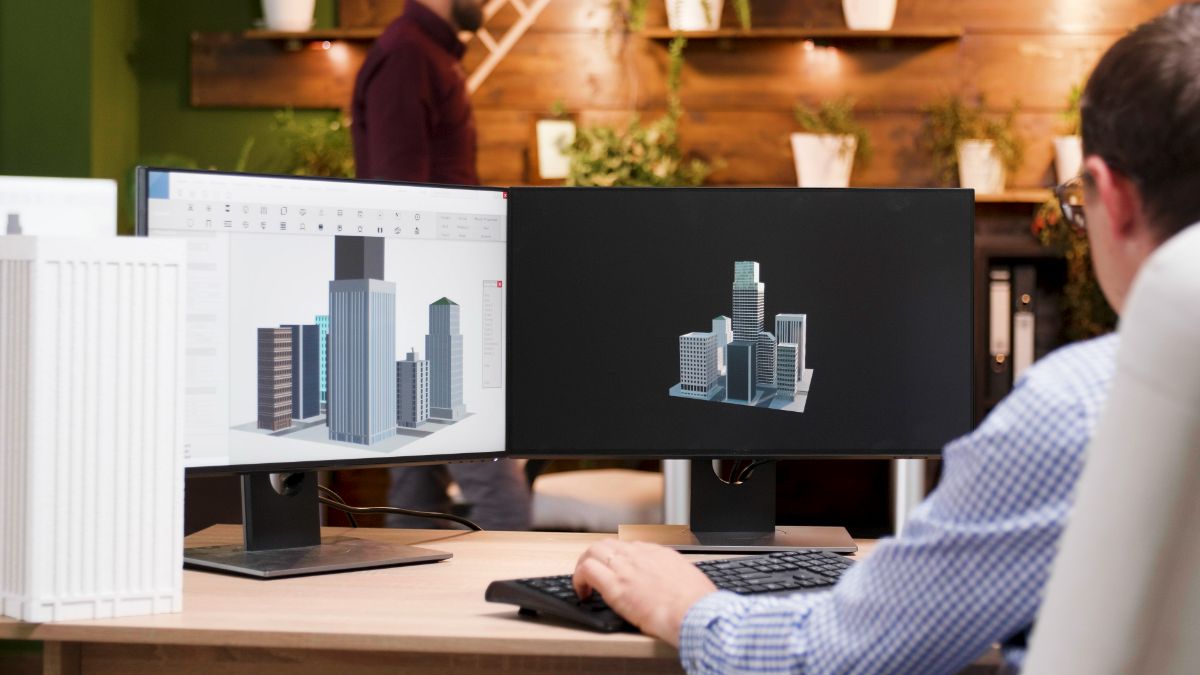

- Computer-aided design and manufacturing

- High-precision machining equipment

- Simulation and virtual prototyping

- Data analytics

Overview

China is equipped with technological advancements in mold-making, benefiting US-based companies seeking high-quality plastic products, such as 3D printing, computer-aided design and manufacturing, high-precision machining equipment, simulation and virtual prototyping, and data analytics. These advancements empower US companies to deliver innovative, consistent, and high-quality plastic injection molded parts to their customers.

In recent years, the mold-making industry in China has experienced remarkable technological advancements. These advancements have revolutionized the manufacturing processes of plastic injection molding, benefiting clients in the United States. The latest technologies have brought about improvements in precision, efficiency, and cost-effectiveness, enabling US-based companies to deliver high-quality molds to their customers.

This blog post delves into the exciting advances in mold making technology for US companies, ranging from 3D printing and computer-aided design to high-precision machining equipment. Join us as we explore these advancements and their significant benefits for companies in the US. Keep reading to discover more about the cutting-edge mold-making technologies that are shaping the industry.

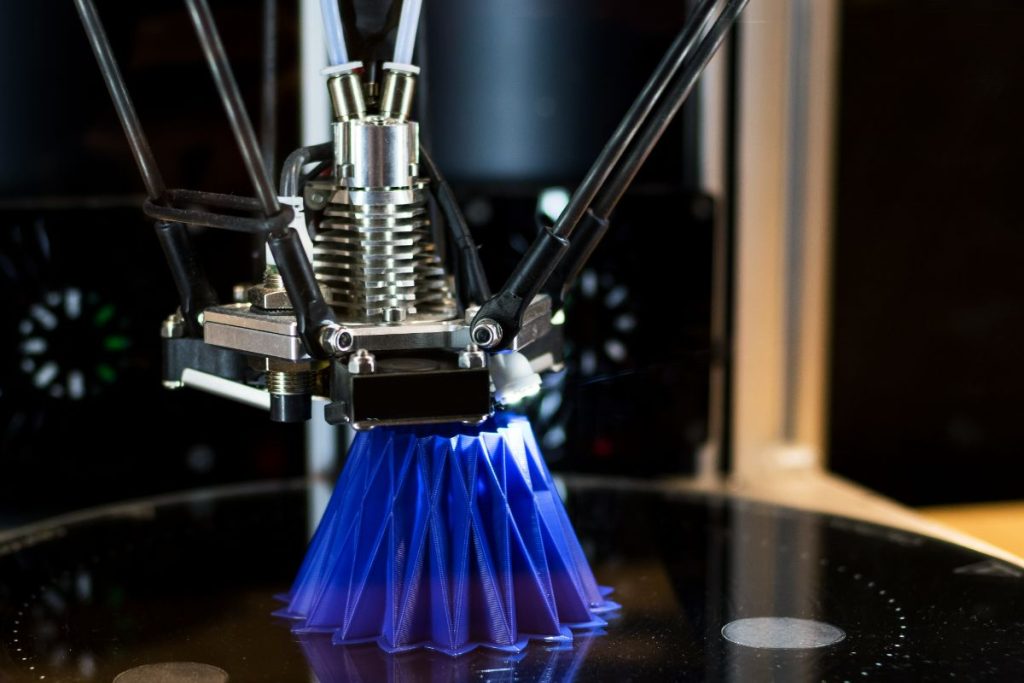

3D Printing

Injection molding is widely used for manufacturing plastic products, but traditional mold fabrication can be costly and time-consuming. Thankfully, the concept of 3D printing molds offers a more affordable and agile solution. It’s now possible to produce functional prototypes and small production parts in various plastics. This is particularly evident in low-volume production scenarios, typically involving 10-1000 pieces.

3D printing allows engineers and designers in China to prototype injection molds, test different configurations, and easily modify molds. A wide range of thermoplastics, such as polypropylene, polyethylene, thermoplastic elastomers, thermoplastic polyurethane, polyoxymethylene, and polyamide can be used with 3D printed molds.

Moreover, 3D printed molds, dyes, and patterns as complementary tools in molding and casting processes offer advantages over traditional methods like CNC milling or silicone molds, making it an attractive option for U.S. companies seeking innovative and practical injection molding solutions.

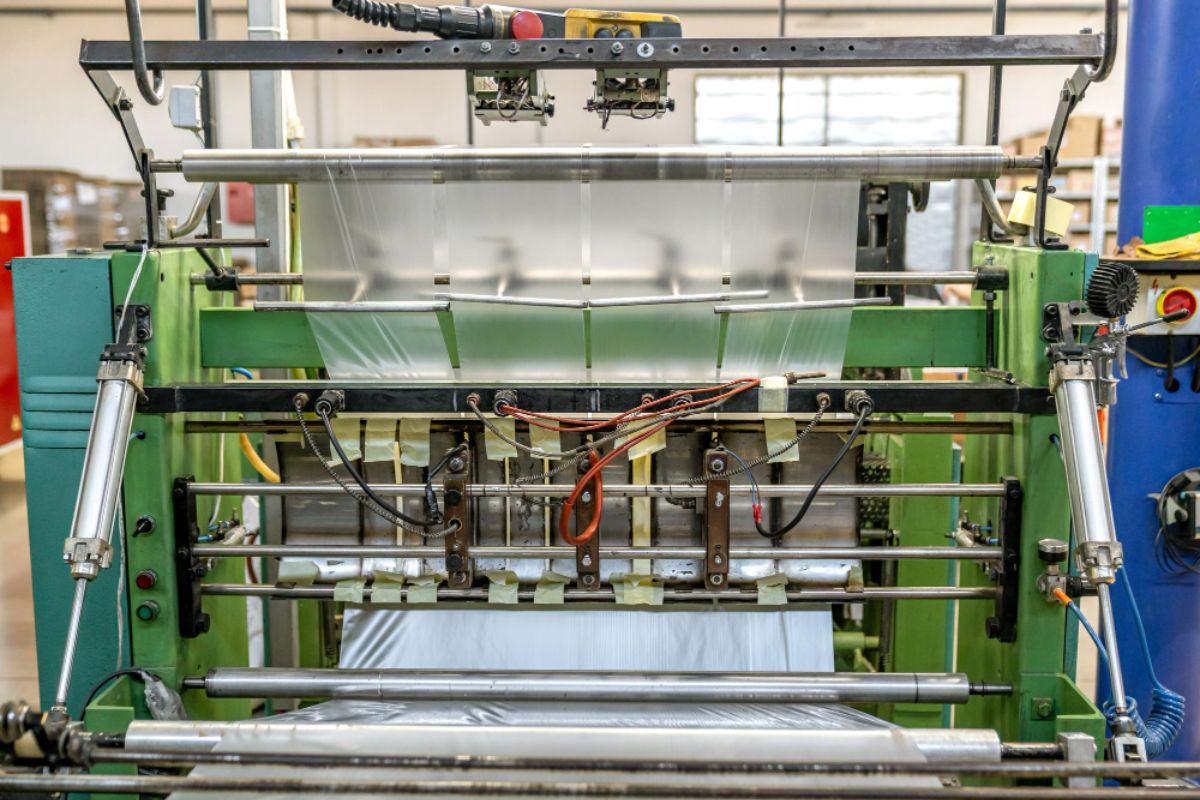

Computer-Aided Design and Manufacturing

Computer-aided design (CAD) is used to create 3D models of the mold and the plastic part that will be produced. This allows engineers to visualize the mold and part before they are built, which helps in optimizing the design further. This ensures that the mold is machined to the correct specifications, and it can also help to improve the efficiency of the manufacturing process.

On the other hand, computer-aided manufacturing (CAM) converts digital design data from CAD into machine instructions. This system uses algorithms and automation to generate precise toolpaths, which guide the movement of injection molding machines, such as the mold, injection unit, and cooling system.

Both are essential tools for plastic injection molding as they help improve the quality of the molds and parts, reduce costs, and shorten lead times.

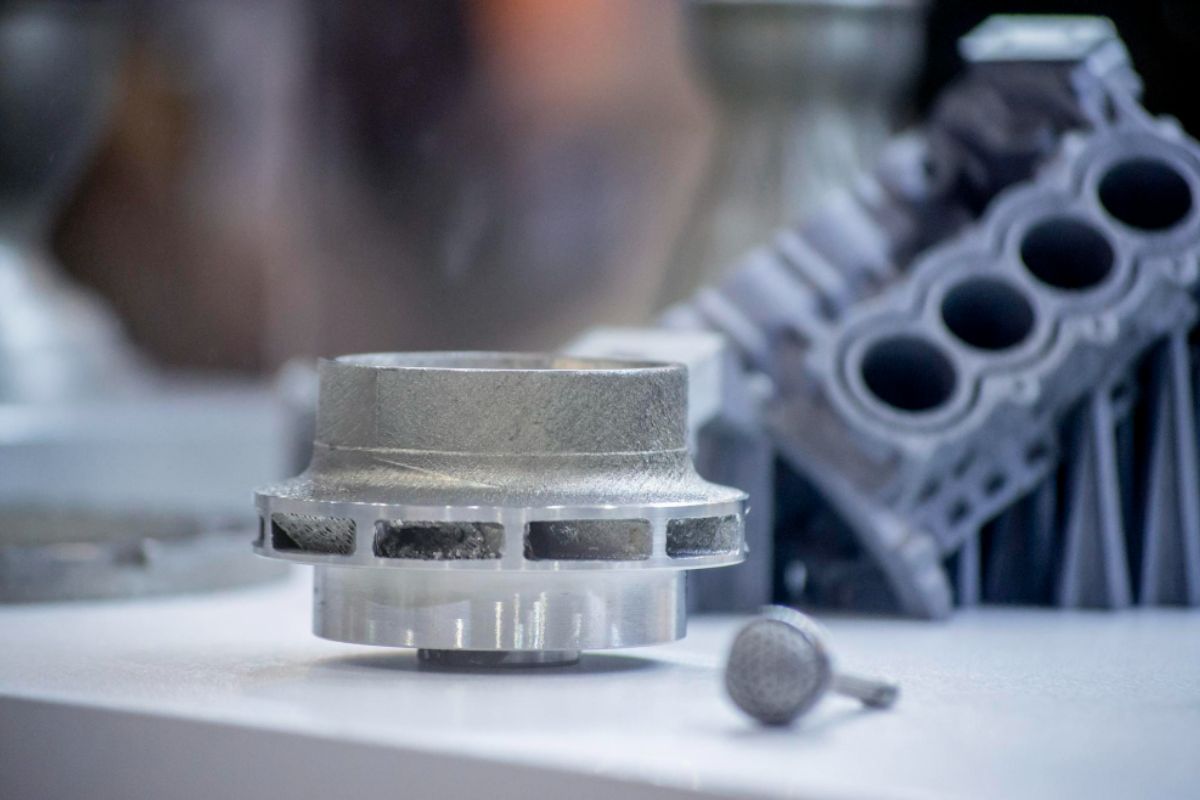

High-Precision Machining Equipment

High-precision machining equipment is advanced machinery and tools, such as computer numerical control (CNC) and electrical discharge machining (EDM) machines used to manufacture molds that require extremely precise dimensions and tolerance.

CNC Machines

These are computer-controlled and turning machines that can perform complex operations with a high degree of accuracy. They can shape and cut various materials precisely, such as plastics, based on digital design specifications.

EDM Machines

They use electrical discharges or sparks to erode a plastic material from the workpiece, which allows for the creation of intricate shapes and features once the plastic is hardened. This process is useful for producing complex, intricate plastic parts with fine surface finishes.

Simulation and Virtual Prototyping

Simulation and virtual prototyping are two important software used to improve the design and manufacturing of plastic injection molded parts.

For instance, simulation models the injection molding process, which allows engineers to see the design of the plastic part and come up with suitable process parameters. Meanwhile, virtual prototyping allows engineers to visualize the part and the mold before they are actually manufactured, which helps to foresee any problems or defects.

Both simulation and virtual prototyping improve the design and manufacturing of plastic injection molded parts. However, they have different strengths and weaknesses. Simulation is more powerful but time-consuming and expensive. Virtual prototyping is less powerful but faster and less expensive.

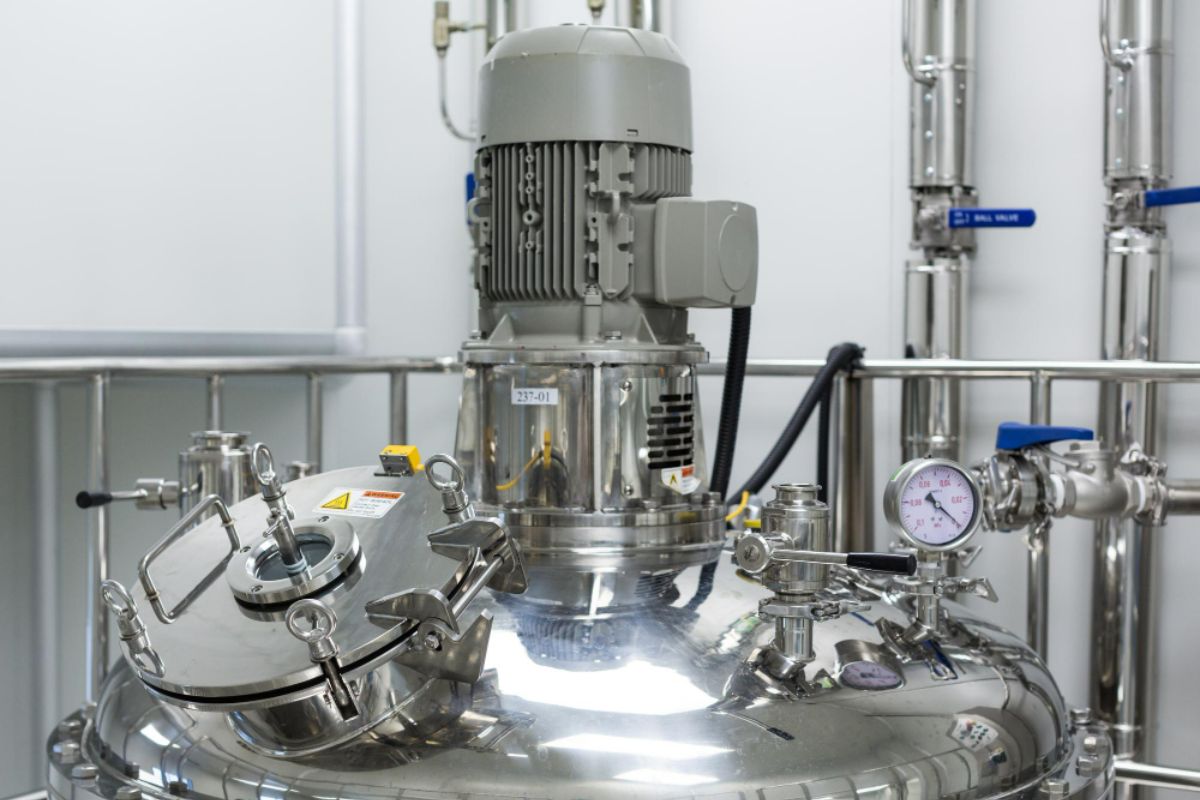

Data Analytics

Finally, data analytics is the application of data analysis techniques and tools to gather, process, and analyze data generated during the molding process. This involves the collection of data from various sources within the injection molding process, such as sensors, monitoring systems, and quality control devices. This helps engineers and technicians extract meaningful insights and make data-driven decisions during the process.

As a result, they can a deeper understanding of the process, which allows the produced plastic parts to be consistent in size, finishes, design, and more.

Key Takeaway

These advances in China’s mold-making technology are advantageous for U.S. companies. It is now possible to create cost-effective and customizable molds whether in small or large volume, which reduces production time and expenses.

Richfields Corporation is a China-based plastic mold maker and injection molding company that offers services in other countries, including the U.S.A. Our team of experts will design and manufacture your plastic parts and deliver them to your business location. Additionally, we inform our clients about the progress of their plastic parts from time to time. Contact us here for more information.