What are the factors affecting the cost of plastic overmolding?

- The design of the part used

- The mold setup

- The type of material used

- The desired surface finish

- The location of the manufacturer

Cost is one of the first considerations when looking for plastic injection molders to design and manufacture your products. There are some factors that affect the cost of plastic overmolding, so it’s important to be informed about these, especially if you’re new to the world of plastic overmolding. Not only will this help you decide, but it will also allow you to work better alongside your plastic molders in a cost-effective way.

This blog discusses the different variables that affect the cost of your overmolded products. Read on to learn more!

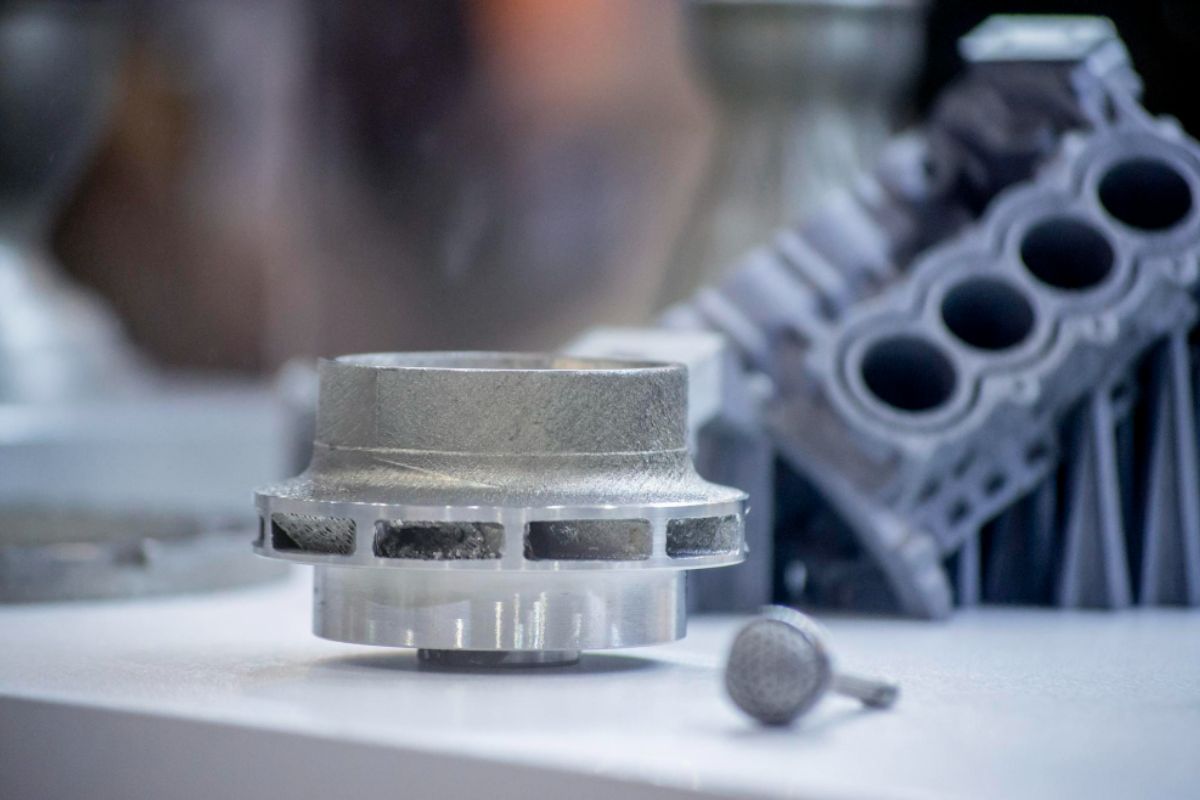

The Design of the Part Used

Plastic overmolding in China is popular for various businesses such as the manufacturing, automotive, medical, and electronic industries because it can accommodate a wide selection of designs in different materials, combinations, and formats.

For instance, a toothbrush is made using the plastic overmolding process. It begins by providing a design that matches the shape of the toothbrush and injecting molten plastic through a hot channel nozzle into the mold. After that, the blind holes are molded into the toothbrush head to accommodate the bristles. The toothbrush is then cooled and ejected from the mold-making machine and the bristles are stapled into the pre-molded blind holes.

Knowing the design of your product will help you a lot with the possible cost of injection molding. Here at Richfields, we make sure that our clients are educated by our expert team about the cost of overmolding their products.

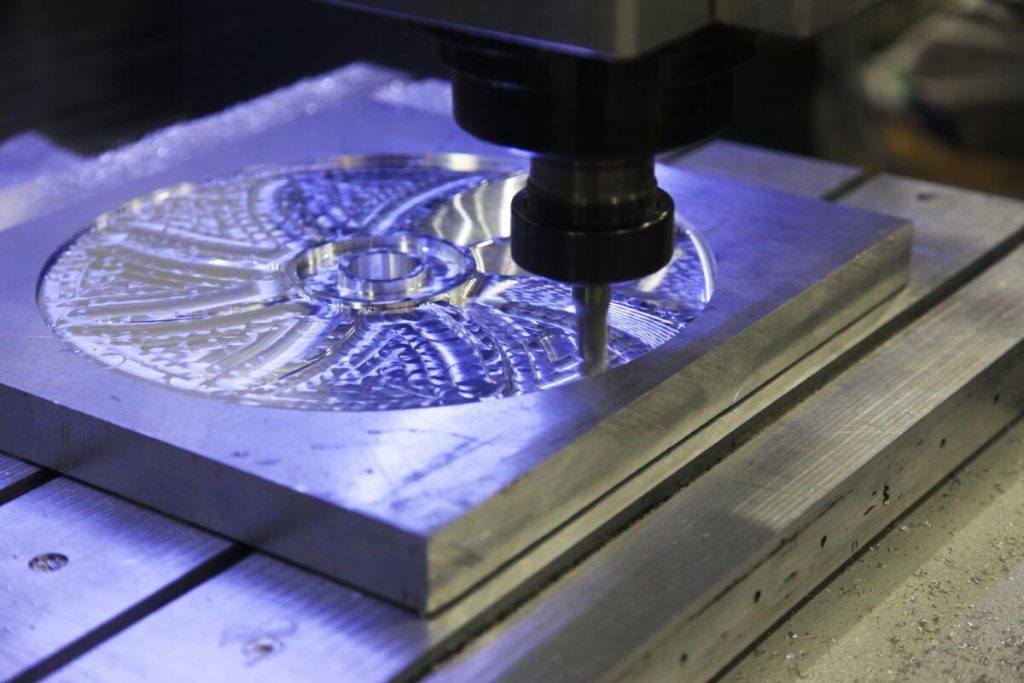

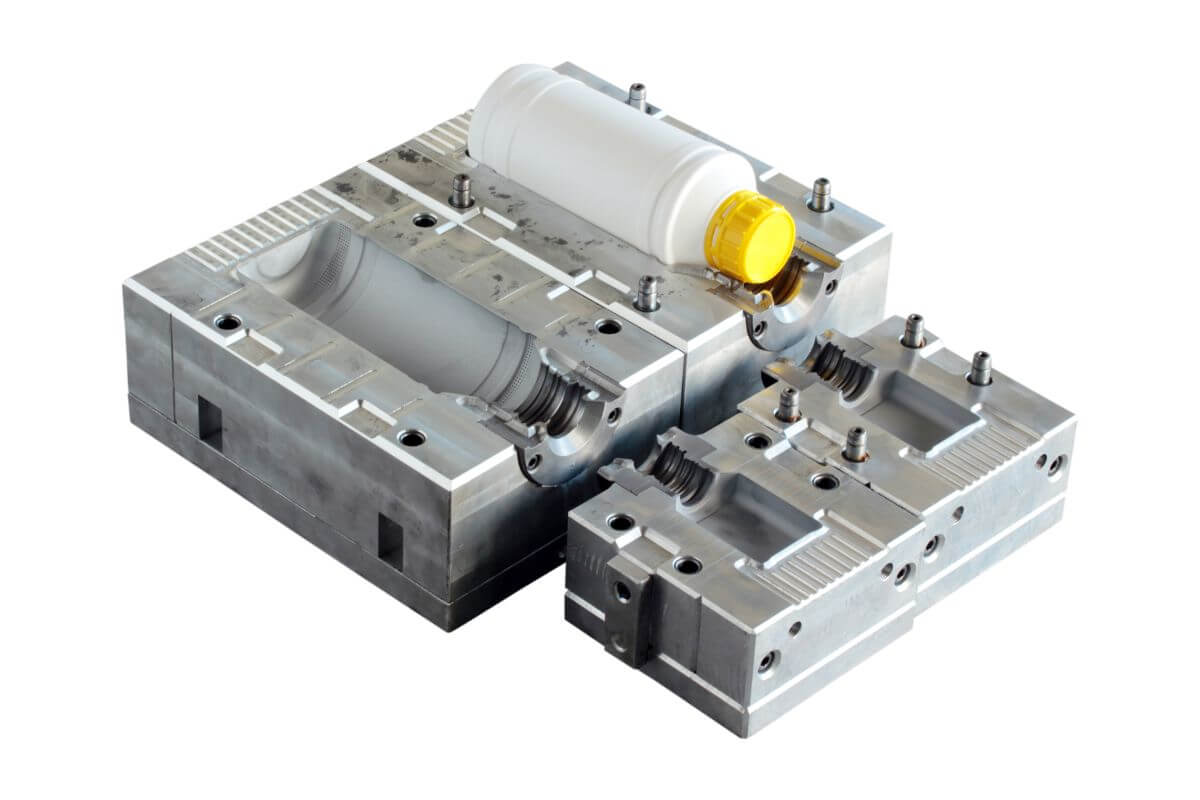

The Mold Setup

The mold setup used in the overmolding process is made of steel, thanks to the alloy’s extreme durability that can withstand the repeated heating and cooling cycle of the process as well as the injection of high-pressure materials. It guarantees that the condition of the product remains good even for an extended period.

Our team here at Richfields only uses a type of steel that won’t react differently when in contact with plastic materials to ensure that the latter won’t behave differently during the process. It helps to make the final product efficient compared to when using less durable steel such as low-carbon steel.

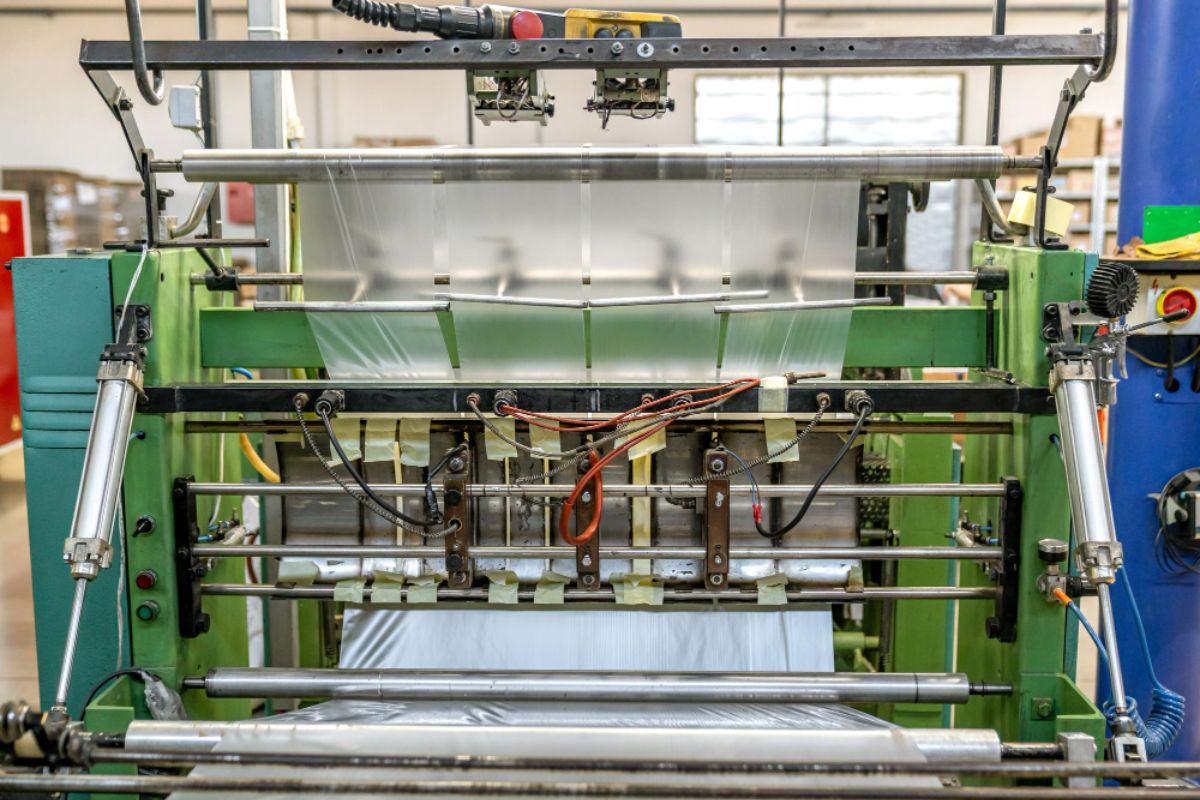

The Type of Material Used

Another factor that you need to consider in plastic overmolding is the type of material used for your product, particularly the resin. It affects the cost of the process, so you must choose the right material since it builds up your product.

At Richfields, we use common resins including Polyetherimide, Acrylonitrile Butadiene Styrene, Polyetheretherketone, Polymethyl methacrylate, and High-density polyethylene. Each of these makes up a distinct product. That’s why you have to be very meticulous when choosing a resin, along with its grade and color, especially if you’d like to produce hundreds or thousands of products.

If you’re still undecided about what resin type to choose, our team can suggest the right one based on the product you’d like to produce.

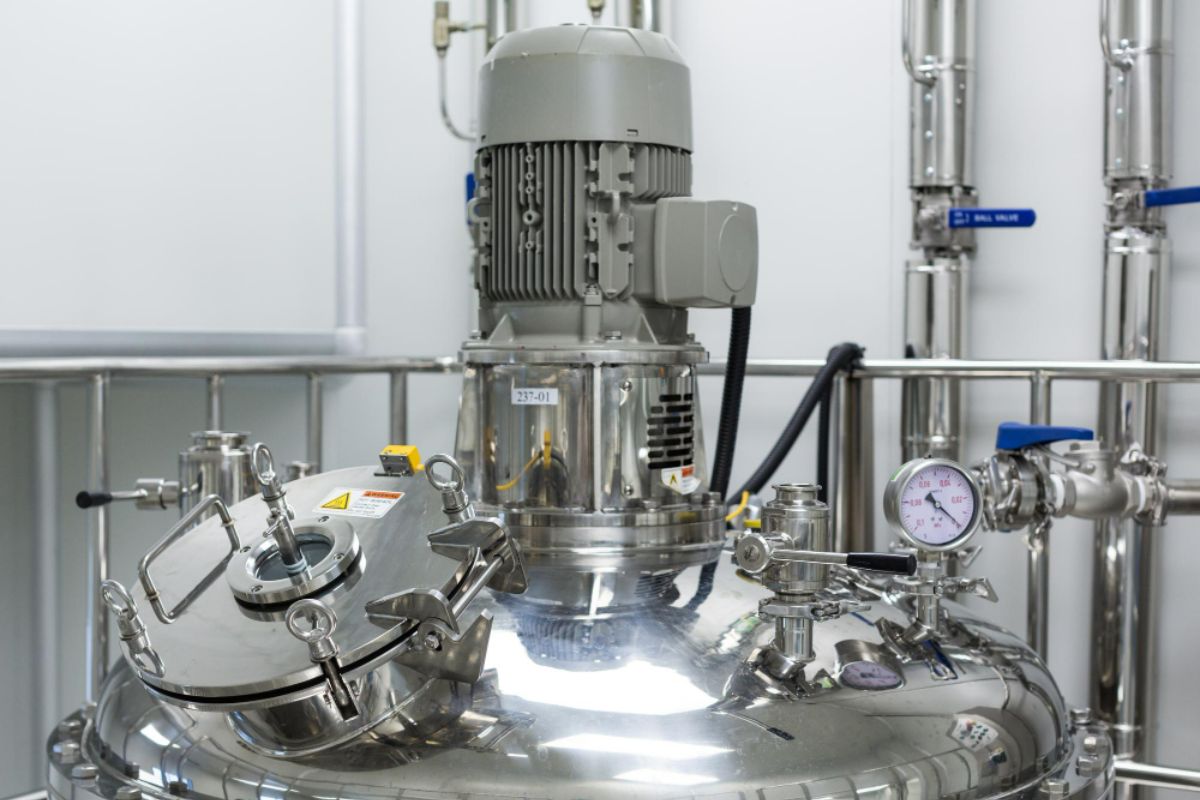

The Desired Surface Finish

Richfields knows the importance of the surface finish because it affects the overall look of a product. A high-quality finish would usually be done using advanced technology and equipment to ensure that the size, shape, and parts of a product are all equal.

On top of that, your desired surface finish merely depends on the purpose of your product. For instance, you’d want to make it more appealing by adding more aesthetic value to avoid any little imperfections, so it could affect the cost of the overmolding process.

The Location of the Manufacturer

Last but not the least, the location of the plastic injection molder is relevant to the cost of your products because of the transportation and shipping costs that it will require once they are set to deliver to your address. However, these are not the only concerns here. There are plastic injection molding companies working in their off-site factories. Meaning, their manufacturing facilities are located away from their primate site causing you to pay for additional shipping and handling cost.

Fortunately, if you work with Richfields, the leading plastic injection molding company in China, you won’t have to pay an expensive cost due to our cheap labor cost that affects the overall manufacturing cost of our plastic overmolding.

On top of that, we have a large and experienced team that specializes in injection molding, which means there are plenty of options waiting for you when you partner with us.

Key Takeaway

Our expert team just informed you about the factors that affect the cost of plastic overmolding. This way, you’ll get an idea of how we estimate the cost of your specific requirements.

At Richfields, our plastic overmolding process is affordable, as we are one of the largest plastic injection companies in China. You’d be surprised to know that we offer cost-effective injection molding solutions to ensure your plastic products are made with high-quality materials. For inquiries or partnerships, please feel free to contact Richfields today!