What are the different applications of overmolding?

- Hardware tools

- Surgical devices

- Everyday household items

- Car trims

- Cookware

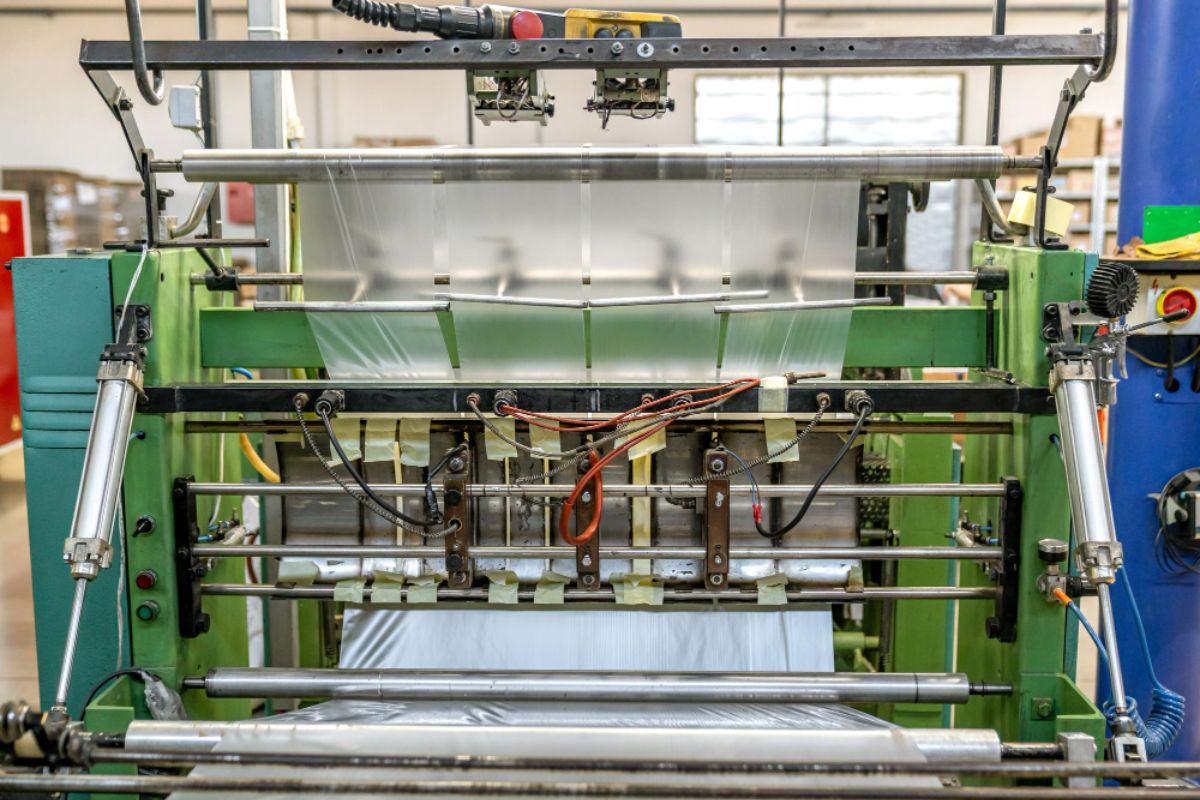

When it comes to manufacturing OEM products, consumer goods, or aftermarket components, injection molding remains to be a reliable method. Various types of thermoplastics such as ABS, polyethylene, polystyrene, HDPE, and many more, can be used in creating durable, ergonomic, and high-grade plastic products. A sub-branch of injection molding, overmolding has come to be a time-tested technique in manufacturing such plastic goods. In particular, the applications of overmolding can range anywhere from handy hardware tools, to high-precision surgical devices that are used in the medical field.

What Is Overmolding?

Before looking into the many uses of overmolding, it’s important to get an understanding of what overmolding is. As the name suggests, overmolding is a kind of injection molding wherein two materials — usually a rigid plastic and a TPE (thermoplastic elastomer) are molded together. First, the rigid plastic material acts as a substrate wherein the rubber TPE is overmolded onto it. Then, the two materials combine into a single product that has a rigid bond, making it ideal for use by end-customers.

You may not notice it, but you’ll find different products around you that have undergone overmolding production. Although the method is simple, its wide use in different types of industries has led to ease of use and practicality in many ways. Read on to learn more.

Hardware Tools

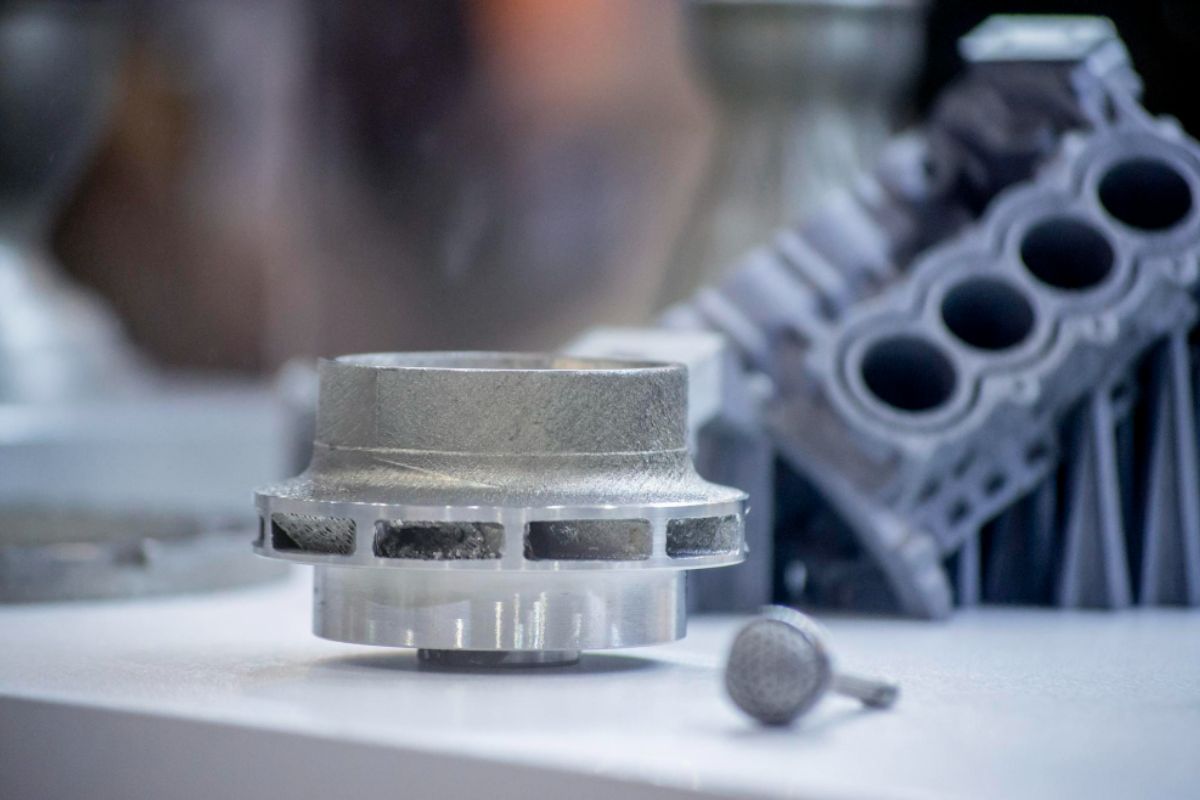

A perfect example of overmolding can be found across different hardware tools. These can range from screwdrivers, pliers, wrenches, hammers, tape measuring devices, pocket knives, blades, and the like.

In these materials, the main machining components are usually made out of tool steel that is capable of cutting, bending, drawing, punching, and other types of fabricating techniques. Before the steel becomes usable, however, the end-user should be able to handle these tools in a safe and ergonomic method — this is where overmolding comes in.

Without overmolded handles, using these everyday tools can be difficult, whether in repairing automotive parts, or working on any home-improvement project. Different plastics can serve as the substrate for the overmolded process. This substrate will then be combined with a rubberized plastic in a two-step injection molding process to complete the handle and improve the user’s grip on the tool.

Surgical Devices

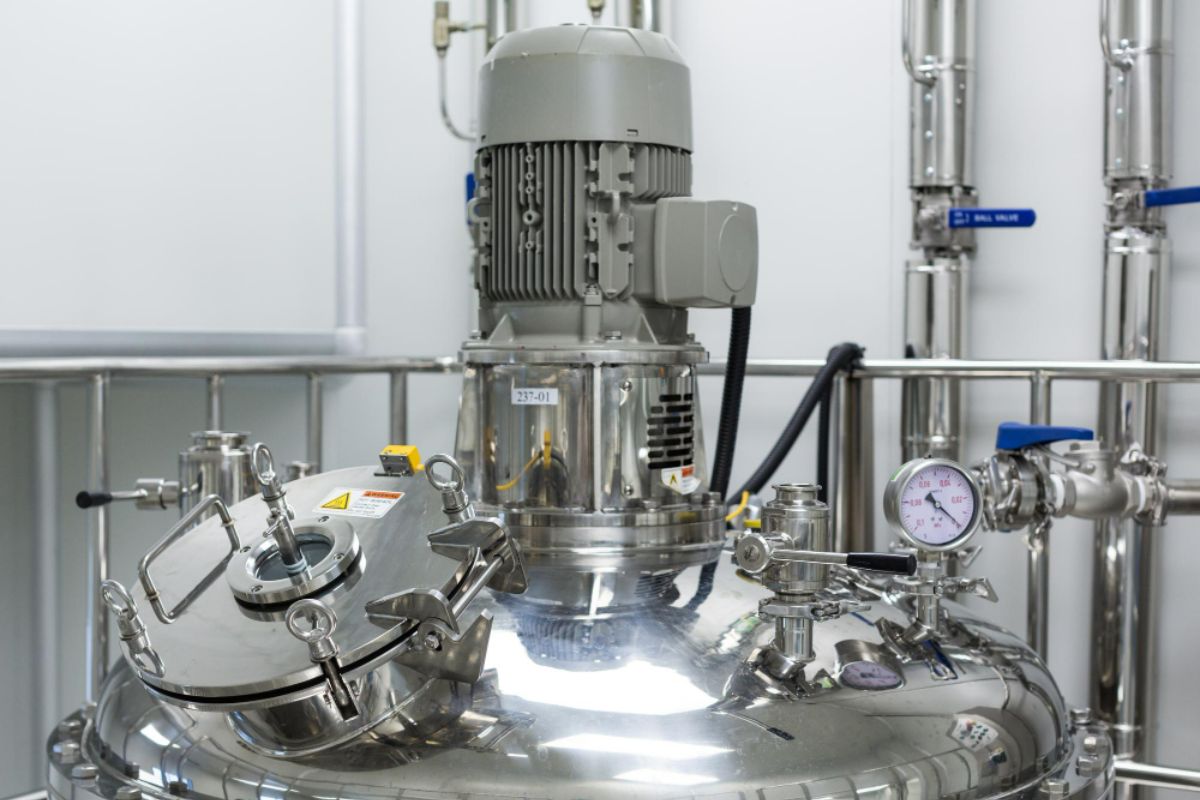

When it comes to the medical industry, precision and product safety are two considerations. Professionals such as doctors, surgeons, and nurses should be able to rely on a safe plastic material when using different types of surgical tools. More than just that, these tools should be sterile and can be easily-cleaned so as to prevent any form of contamination.

With that said, overmolding has also enjoyed wide use in this industry. Different medical products, such as equipment housing and surgical devices are made through overmolding in order to create a finished part that improves ease of use. Some examples include syringes, patient monitors, needles, catheters, dilators, soft-touch buttons, and many more.

Everyday Household Items

As mentioned before, one of the advantages of overmolding is that it improves grip, ease of use, and cleanliness in many products. Aside from these, overmolding also makes use of materials that help improve a product’s chemical resistance, vibration dampening, sound insulation, and many more.

It’s no surprise that you’ll find different household items that are made from overmolding, such as toothbrushes, kitchen utensils, portable electric fans, mirrors, pens, multi-port chargers, shampoo bottles, reusable food containers, and the like. Overmolded products are designed to improve the quality of life of the end-user, even when it simply means making the products easier to clean, use, reduce wear and tear, and prolong the shelf life.

Car Trims

Car trims, also known as car moldings are the parts that are found in different areas of the vehicles, such as the door edge, side body, fender, bumper, wheel, and other areas in the interior. Although car trims are often installed because of their decorative appeal, they do have some functional benefits, especially in reducing the weight of the vehicle.

As discussed in the previous sections, overmolding has numerous functional advantages. Going beyond that, overmolding is also a versatile plastic manufacturing technique because of its many creative uses. Automotive trims can be fashioned in different types of pre-set or customized colors preferred by the customer.

These overmolded trims can also undergo another process known as insert molding so that they can be molded with other materials — think steel, chrome, or any kind of metal plating.

Cookware

Food-safety is a must when using plastic in products such as kitchen utensils, cookware, and food containers. Keeping this in mind, it’s no surprise that overmolding should be a key technique in manufacturing cookware parts and components.

Some applications of overmolding in cookware include spatula handles, pot covers, strove trimmings, knives, cutting boards, and many more. These products make use of high-quality plastics that won’t affect the taste and quality of food, thereby increasing the safety of the consumer.

Key Takeaway

In this guide, you’ve learned the most popular applications of overmolding. Although the technique is relatively straightforward, it’s widely used in crafting everyday household items, hardware tools, cookware, car trims, and even surgical devices. It provides unparalleled benefits in improving ease of use as well as user experience and products design.

Are you looking for a company that provides overmolded parts? Contact Richfields Plastics and see what they can do for you! You may also check out their products — guaranteed that they can meet all your overmolding, prototyping, and injection molding needs.