What are the causes of burn marks in plastic injection molding?

- Issues with the machine and molding conditions

- Issues with the mold

- Issues with the material

Injection molding, while a very advanced production method, is not exempt from error. One of its most common defects is burn marks, which affect the overall quality of the plastic component.

These errors can show up at any point of the molding process, which means you have to be ready to find the root cause of it when it arises. This is crucial not only in saving you from replacement costs but also in reducing machine downtime and material efficiency.

Not sure how to solve this defect? We cover the common causes of burn marks in plastic injection molding to help you deal with this potential hurdle.

Why is burn marks a big issue with injection molded parts?

Also called gas traps and dieseling, burn marks are quite literally as the name implies: burns. This is much different from, say, brown streaks and swirls that you might find on the surface of a freshly molded plastic component.

If you’re unsure that the defect you’re seeing is a burn mark, look closer. They appear to be black or dark brown deposits on the part or mold itself — sometimes, these marks are covered in smoot. There may even be indentations from where the plastic has burned.

Unfortunately, burn marks are more than just an aesthetic problem. These defects can also affect the structural integrity of the component, as they cause degradation within the material and mold properties. Any burn mark poses the risk of eventual part failure.

So how does one fix a burn mark? Here are the three possible causes to look at:

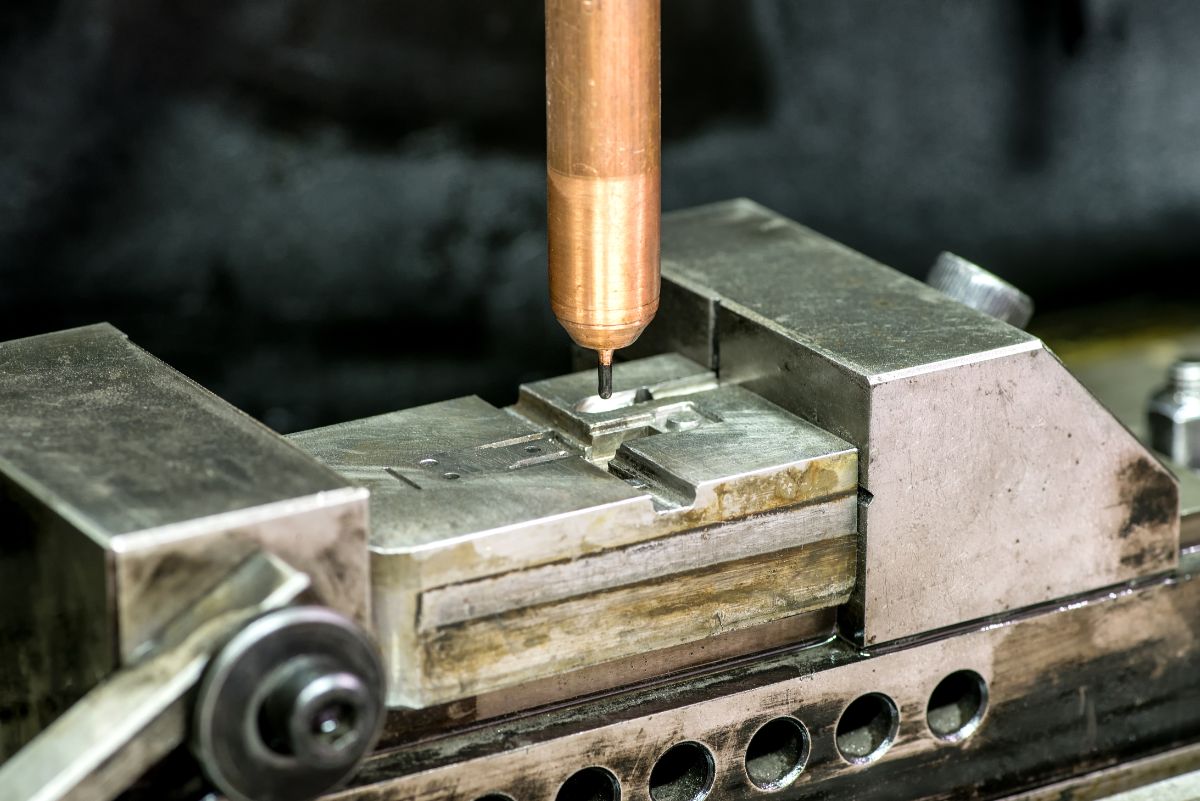

Issues with the machine and molding conditions

One of the most common culprits of this defect is the machine or the process in which it molds the molten resin.

In some cases, the burn marks may be caused by the molding conditions. The molten resin may be flowing into the mold too quickly, or the backpressure may be too high. Problems with the machine hardware, such as gate sizing, nozzle size, and more can also be the reason behind a burn mark.

Here are the signs to look out for that indicate the problem most likely lies with your machine and the molding conditions”

- Burn marks at the end of the filling part — indicate that the injection speed is too high, or the pressure is too high. This causes the fill rate controls to be ignored, which causes burning. Try lowering the pressure or speed.

- Black streaks in molded parts — indicate that the gate size is positioned wrong, or is too small. This causes resin melt flow to be too low, eventually leading to burnt streaks within the material.

- Black streaks in molded parts — may also indicate that the nozzle size is too small, which causes the same too-slow melt flow. Try opening the nozzle orifice.

- Black specks or color striation in molded parts — indicates that the screw and barrel need to be cleaned, repaired, or replaced.

Issues with the mold

If the defect isn’t caused by the machine, the next thing to check is the mold itself. If the mold is not properly manufactured or doesn’t present the right conditions, then it can cause problems with venting and resin flow. As a result, the resin is likely to burn at the edges.

These are the signs that your burn marks are likely due to issues with your mold design:

- Burn marks near the end of the fill — indicates there is improper venting. You can try slowing down the injection rate to allow for more venting as the resin flows and cools within the mold.

- Burn marks on the mold or destroying the mold — indicate that air is being trapped within the injection cavities. May also indicate that the mold was not designed or constructed properly. Both cases can be solved by a redesign or adding more vents.

Issues with the material

Lastly, you might have to check if the problem lies with the resin you’re using for your injection molding project. If the resin is wet or has an excessive moisture content, then this liquid will burn in the injection molding process. Hence, the burn marks in the finished product.

Some resins, such as PVC and acetate, are also more prone to burning — even without high moisture content. Keep this in mind if this is the material you’ve selected for your project.

One sure sign that the material is the cause of your defects is if the resin chars as it enters the mold. When this charred resin enters the melt stream, it becomes molded into the final product. If this happens, check for moisture as well as resin temperature. The temperature might be too high for the resin, in which case it should be recalibrated.

How to prevent burn marks in plastic injection molding

To fix the issue of burn marks, you not only have to know its root cause but also how to fix the root cause. Because burn marks can be caused by many different factors in the injection molding process, doing both can be tricky — especially when this is your first plastic project.

This is why the best way to address burn marks in injection molding, and prevent these defects from happening again, is to partner with an experienced injection molding company early on. The services of companies like Richfields — who have decades of experience in resolving defects under their belt — are invaluable when it comes to ensuring the quality of your mold design, mold maintenance, production, and final product.

Key Takeaway

Burn marks are a common injection molding defect. They can cause part degradation, mold damage, and even product failure. But, knowing the common causes of burn marks in plastic injection molding and working with the best injection molder can help you avoid burn marks altogether.