What are the benefits of overmolding?

- Custom plastic parts

- Improved product performance

- Better shock absorption

- Reduced manufacturing costs

The aim of many plastic manufacturing processes is to create a high-precision product free from defects. This is the priority on one such plastic injection technique called overmolding. The benefits of overmolding have been consistently capitalized on, in the industry due to the following: creation of custom plastic parts, better product performance, lower manufacturing costs, and availability of complex designs.

What Is Overmolding?

As the name suggests, overmolding is a plastic injection process that involves the molding of one plastic material over another resin — or metal. The aim of overmolding is to combine multiple plastic parts together in a seamless fashion to create a durable and uniform product. As such, this requires high precision and a consistent application of heat and temperature to ensure the products won’t detach from one another.

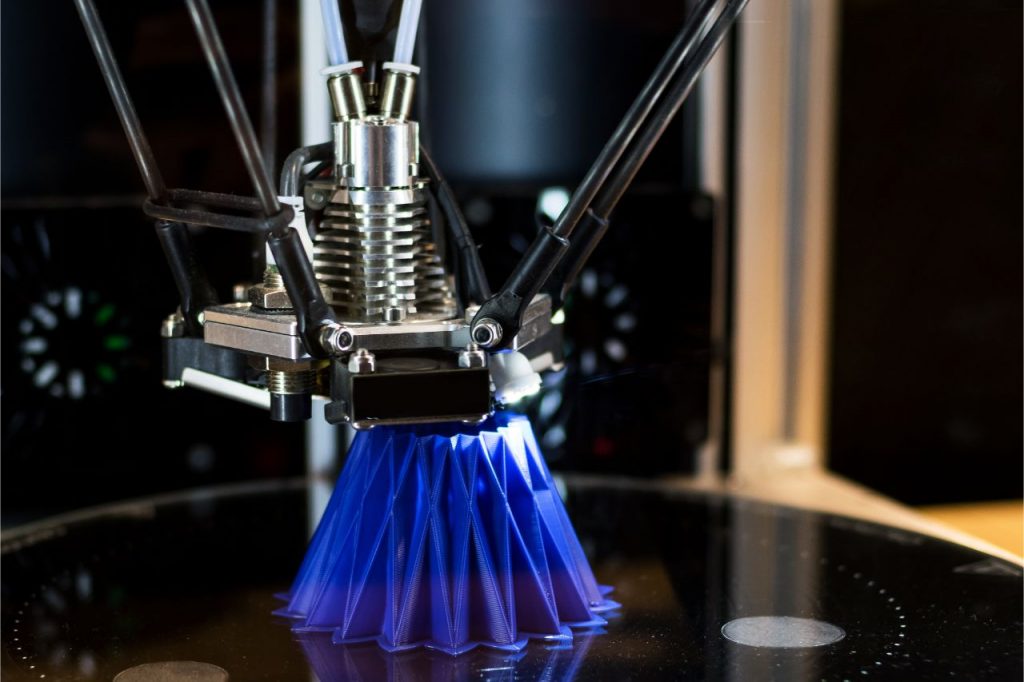

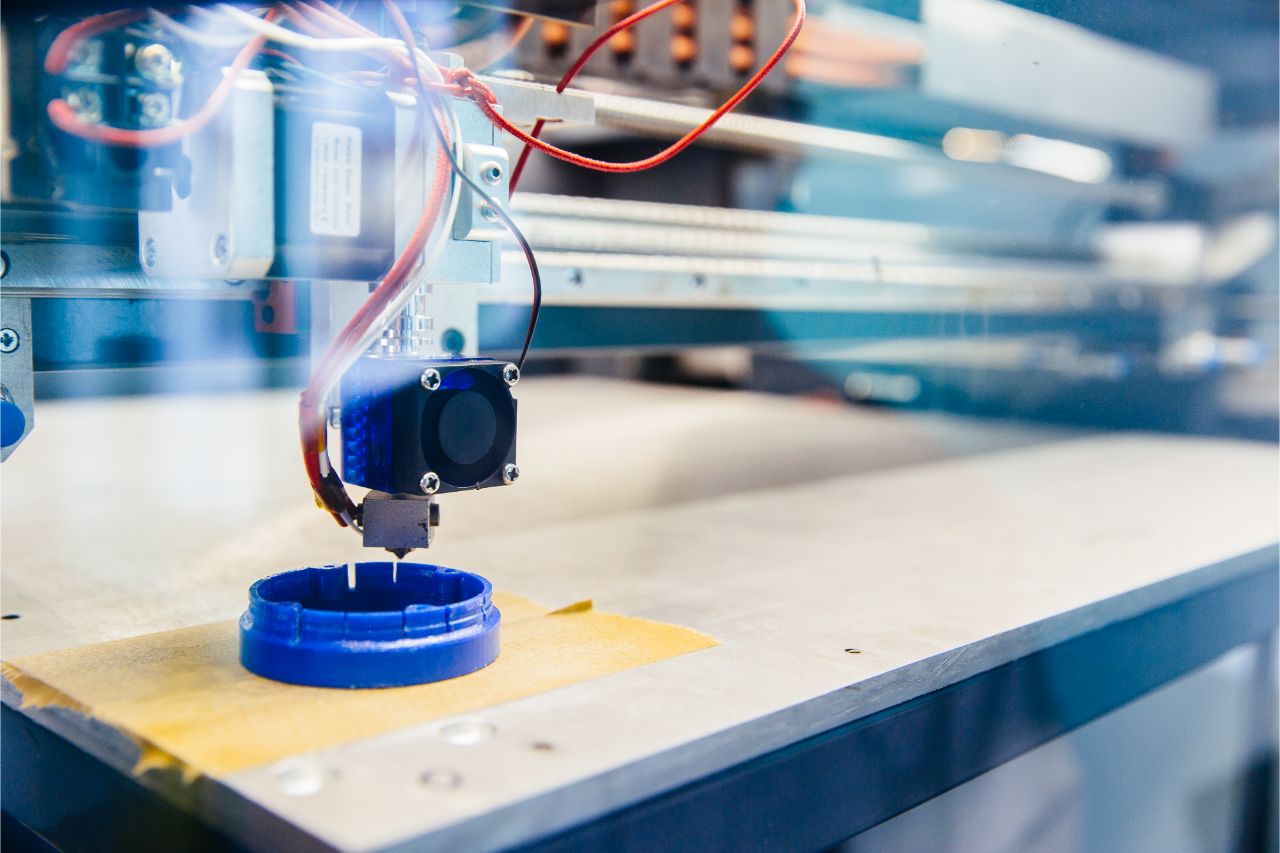

Overmolding is typically classified into two types: insert molding and multiple material molding (also known as two-shot or multi-shot molding). In insert molding, a pre-injection molded product is placed back into a molding machine. TPE (thermoplastic pellets or thermoplastic elastomer) are fed into the machine, molten, and molded over the existing mold.

Multi-shot overmolding on the other hand, involves the use of an injection molding machine that contains two or more barrels. This allows two materials — different or same — to be injected into the same mold in a single cycle.

Instead of creating two injection molded parts separately, overmolding combines every manufacturing phase into a single process without drawbacks on the quality of the finished product. Read on to learn more.

Custom Plastic Parts

One of the advantages of overmolding is that it allows for the design and creation of custom plastic parts for almost any kind of industry. Manufacturers can create overmolded products that have a plastic-plastic or metal-plastic combination with a high dimensional quality.

Some products made through the overmolding technique include grips, handles, knobs, electronic components, moldings, bottle caps, automotive components, and virtually any other kind of consumer or industrial good. Clients can come up with different designs for overmolded products, as long as the raw materials/resins used are compatible with each other.

Improved Product Performance

Although the most common resins used in injection molding have beneficial properties — waterproof, chemical resistant, durable — the addition of another material greatly improves the final product’s performance. Overmolded products are of higher quality because they have the two-material advantage that industries use for different types of applications.

For example, there are tons of hardware tools that are made with a plastic and rubber grip. Some typical components of a hardware tool include a plastic casing, rubber grip, and the cutting/machining part. In this case, the plastic casing is overmolded with a rubber grip made out of silicone, styrene butadiene rubber (SBR), nitrile rubber, and the like.

The overmolded rubber improves the ergonomics of the tool to a significant degree by increasing the grip and preventing unnecessary slippages for the end-user. This also increases the safety of the product, especially when the primary tool component has sharp edges that can cut or pierce.

Better Shock Absorption

Overmolding also provides various products with excellent shock absorption, due to the added plastic resin. With this feature, the product can have a longer shelf life and improved resistance against physical impacts compared to non-overmolded products.

This is an important feature to consider, especially in automotive, structural, or industrial applications where the durability of the material is a top priority.

Some of the resins that can provide excellent shock absorption include rubber, silicone, or neoprene. With this in mind, car components like hoods, door frames, fenders, and the like can be overmolded with the materials above. The additional shock absorption can allow car makers to gauge the safety of the components through crash/impact tests. They can use the information to make more modifications to the car part and fabricate higher quality components that help improve driver safety.

Reduced Manufacturing Costs

As mentioned before, overmolding is done in a single cycle time. This means that the process is expedited due to the absence of two or multi-part assembly. Because overmolding eliminates the post-assembly phase, they are able to reduce their manufacturing costs and speed up the entire process. This results in shorter lead times and a faster rate at which the final product can be distributed to different tiered suppliers/manufacturers for OEM or aftermarket use.

With lower manufacturing costs, the injection molding company can increase their production capacity. They also reduce wastage of raw materials that can result during assembly — i.e. through cutting and removal of excess/unwanted parts. Likewise, the expense that would be passed onto the consumer will be lowered with the reduction in costs.

Key Takeaway

This simple guide has highlighted just some of the many benefits of overmolding. As said before, it’s a kind of injection molding process where two differing resins/materials are combined together in a single mold cycle. This is a single-assembly process that manufacturers and consumers alike have benefitted from, due to its simplicity, low cost of manufacturing, better product performance, and custom plastic parts.

Always make sure that your products are overmolded by a professional injection molding company like Richfields Plastics. Their prototyping services in China can help you come up with your preference of custom-built plastic products that are 100% suited for any type of use. Get in touch with them for more information on their overmolding services.