What are the applications and uses of Polypropylene?

- Food Packaging

- Medical Supplies

- Plastic Furniture

- Automotive Parts

- Plastic Films

Plastic is arguably the most versatile material used in the manufacturing industry as it can be molded into different shapes to produce a wide variety of products. This versatility has made plastic one of the most popular materials in the manufacturing industry. It is convenient, durable, and very flexible.

When it comes to producing plastic products, it is important to use the right type of plastic for the best result. There are many types of plastic used for plastic injection molding, and one of the most widely used types is polypropylene. While other types of plastic have also seen wide usage across different industries, polypropylene has become an in-demand material due to its unique features and qualities.

What are the applications and uses of Polypropylene plastic?

Polypropylene is a type of plastic that is known for being a tough and rigid material. It is distinguishable by the way it shines. These qualities make it very suitable for the manufacturing of different products. With that in mind, here are some of the most common applications and uses of polypropylene plastic.

Food Packaging

Polypropylene is a plastic that can be used as packaging material. There are two types of packaging that can be produced out of Polypropylene, namely Flexible and Rigid Packaging. Flexible plastic packaging is defined by its transparent nature and is commonly used as plastic containers for food and other kinds of items. Rigid packaging, on the other hand, is a type of packaging that is thicker and opaque. This is commonly used to create packaging such as plastic plates, cups, and utensils, as well as bottles and pots. Polypropylene is also a microwaveable material, which is a crucial feature for food containers.

Medical Supplies

The medical industry is one of the biggest users of plastic as it is a durable and flexible material that can be used for various medical applications. Polypropylene is used to create medical products and tools such as Petri dishes, syringes, specimen bottles, pans, vials, and pill dispensers. Another advantage is that the plastic is resistant to strong chemicals, steam sterilization, and bacteria, which are important qualities needed for medical supplies present in a health facility.

Plastic Furniture

The rigid nature and shiny surface of polypropylene make it an ideal material to create different kinds of plastic furniture. These pieces of furniture can include chairs, tables, stools, drawers, and even large cabinets. Compared to using materials like wood and metal, plastic furniture is lighter and much easier to produce, making them great alternatives. For companies looking to manufacture light, cheap, and durable furniture, using polypropylene is the best option in the market.

Automotive Parts

Polypropylene plastic is a very common fixture in the automotive industry. Being affordable, easy to mold, and simple to produce makes it a very common material for different kinds of plastic parts and components. These automotive parts include car battery cases, car bumpers, fenders, dashboards, instrument panels, door trims, and more. These plastic parts help lessen the overall weight of the vehicle. This helps make your car perform better while still having a strong material that can keep you safe while driving.

Consumer Products

One of the most common applications and uses of polypropylene is for the production of consumer products. These products can range from appliances, toys, luggage, carpets, mats, rugs, and other kitchen items. Its durability and resistance to high temperatures make it an ideal material to use for kitchen and home appliances such as washing machines and coffee makers.

Along with being used for home products, it can also be used to produce parts like bottle caps and even components for machinery. If you are looking to manufacture a wide variety of products without needing to change materials, polypropylene offers you the widest set of options.

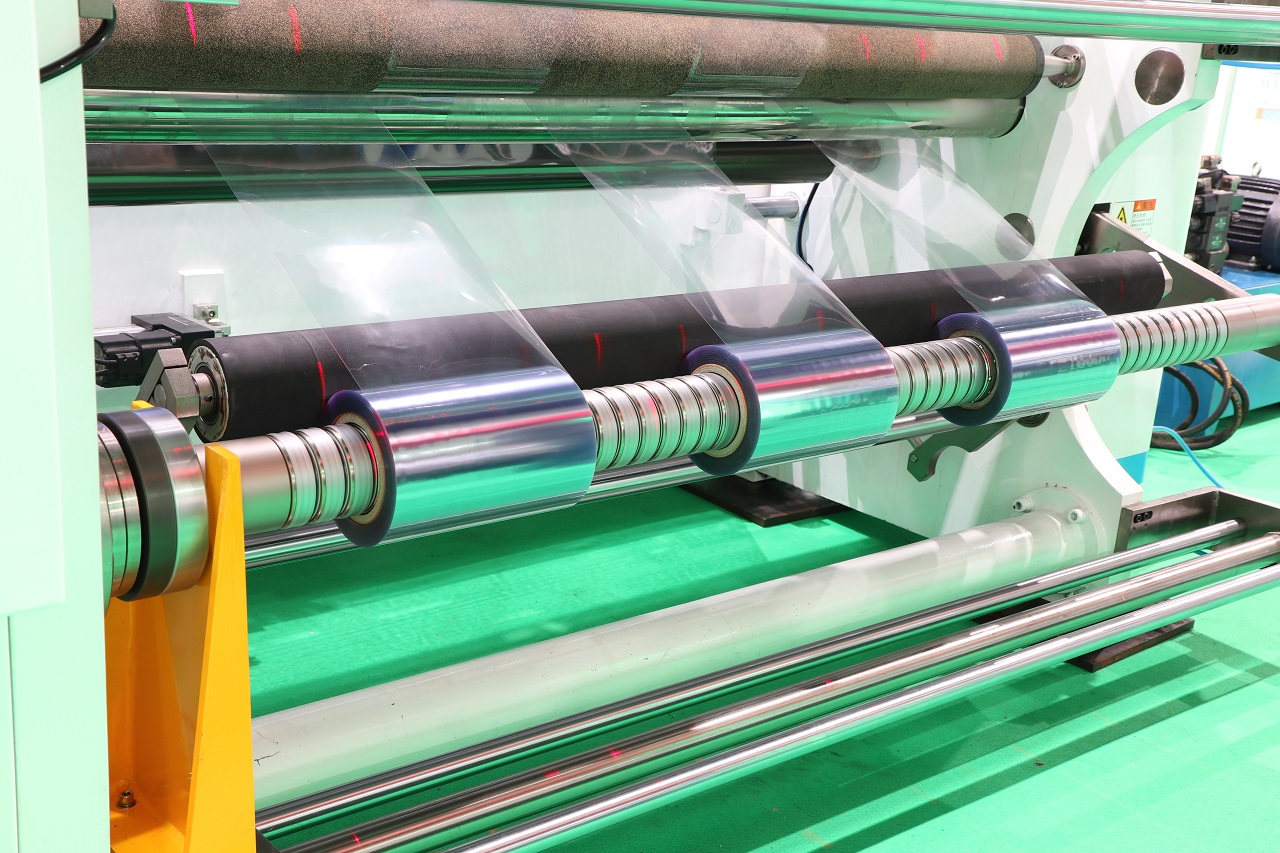

Plastic Films

Another popular product manufactured using polypropylene is PP film. This type of film is known for its strength and resistance against tears, punctures, and high temperatures. It can be used for products like packaging and industrial parts. Compared to using thinner types of plastic that can break easily, using PP Film is a much better option that can generate a better overall product.

Key Takeaway

Plastic is a very abundant production material that can be used to create many different products. By choosing the right plastic-type, you can maximize the capabilities and quality of your products. Polypropylene is one of the most common types of plastic used in the manufacturing process. With its durability and versatility, you can create a diverse range of parts, items, and products with high efficiency.