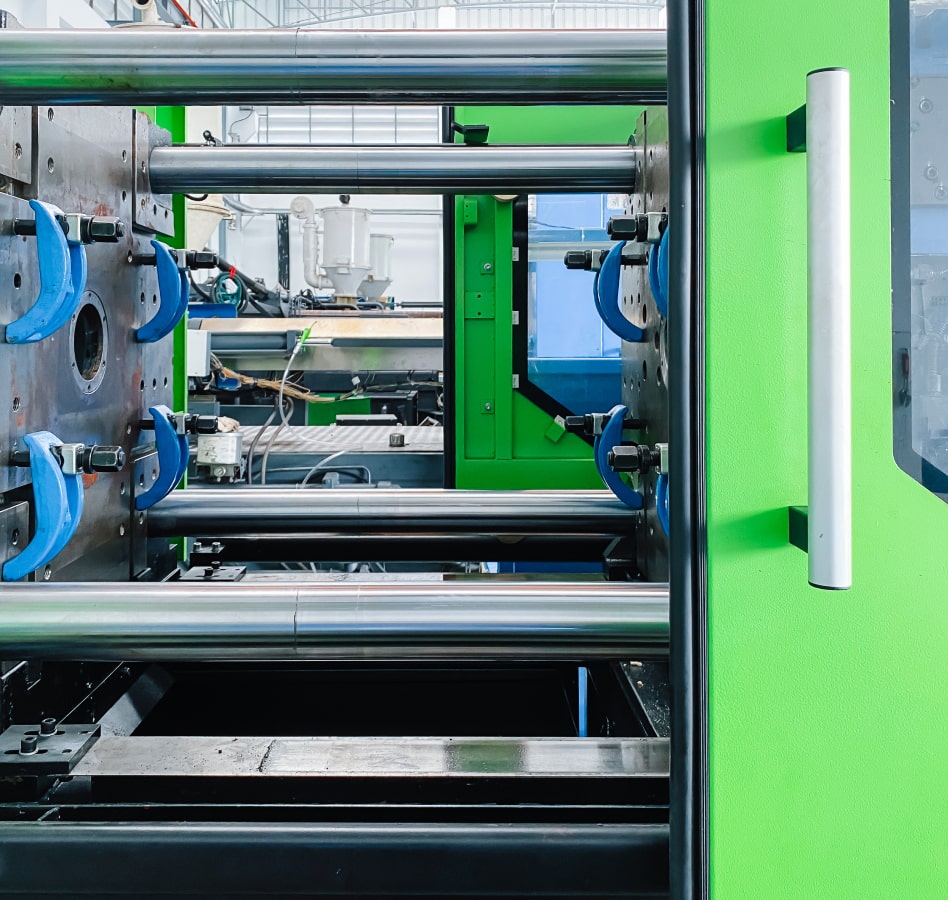

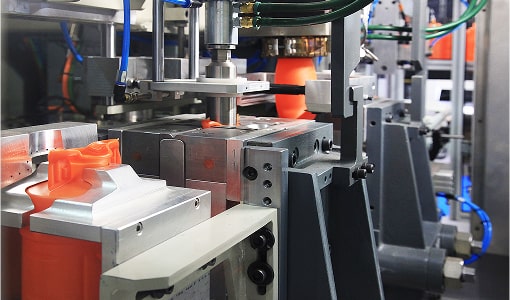

Expert Plastic Injection Molding Services in China for Precision and Performance

When your business demands reliable, high-volume production of plastic materials, from day-to-day essentials to specialized components for industrial use, you need an expert manufacturer you can count on. At Richfields, we specialize in producing top-quality plastic parts, whether it’s food containers, bags, storage bins, toys, kitchen utensils, gadgets, or devices, all made to meet your exact specifications.

For decades, plastic has been a go-to material in manufacturing for its versatility and durability. U.S. businesses partnering with Richfields for plastic injection molding services in China gain key advantages—competitive pricing, minimal production waste, and exceptional service. Discover how we bring precision and care to every project.