September 21, 2025

How to Use 3D Printing in Injection Molding

Overview

- 3D printing has become a transformative tool in manufacturing, particularly when integrated with injection molding processes to improve efficiency and production agility.

- From rapid prototyping and creating 3D-printed molds to producing conformal cooling channels and performing quick mold repairs, understanding how to use 3D printing in injection molding allows your business to reduce lead times, enhance part quality, and lower operational costs.

- At Richfields, we specialize in precision plastic injection molding in China, ensuring your projects benefit from high-quality, reliable production to support your product development and manufacturing goals with confidence.

3D printing has rapidly evolved from a prototyping tool into a valuable asset in modern manufacturing, including injection molding processes. By creating precise inserts, functional prototypes, and even conformal cooling channels, 3D printing can enhance tooling, improve production flexibility, and reduce lead times in injection molding projects.

In this article, we will explore how to use 3D printing in injection molding and how it can support your production goals while improving your overall manufacturing capabilities.

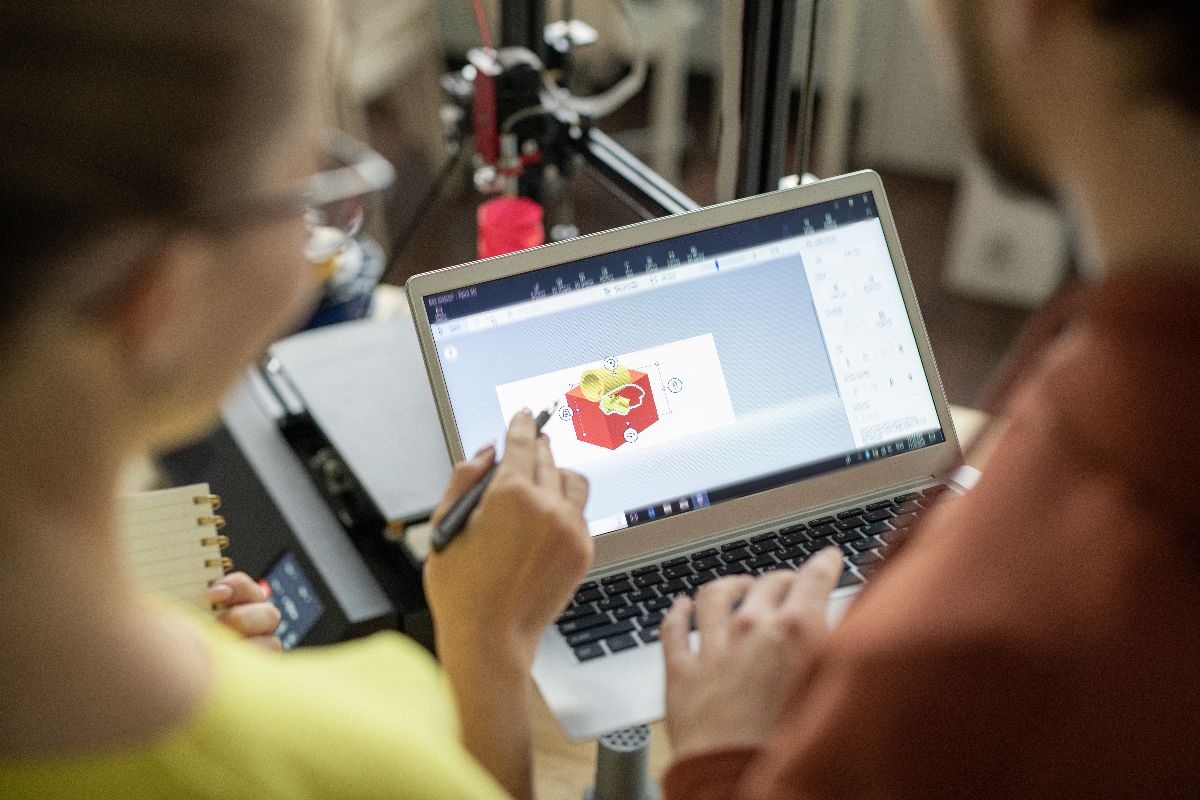

Rapid prototyping is one of the most practical ways to use 3D printing in injection molding because it allows you to quickly create functional prototypes of your parts without the need for expensive steel molds.

Instead of waiting weeks or even months for traditional tooling to be machined, you can produce a 3D-printed prototype within days, enabling immediate evaluation of the part’s design, fit, and function. This helps you identify design flaws, test assembly with other components, and gather feedback early in the development stage, significantly reducing the risk of costly design errors once full-scale production begins.

For your business, using 3D printing for rapid prototyping offers clear advantages. It shortens product development timelines, allowing you to bring new products to market faster and respond to customer or market demands with agility.

These 3D-printed molds, often made from high-strength resin or metal, can be used to validate part designs, perform functional testing, and conduct market testing before committing to full-scale production tooling. This flexibility enables you to bring products to market faster, adjust designs based on customer feedback, and reduce the risk of investing in molds for products that may require further refinement.

3D-printed molds can also incorporate complex conformal cooling channels that traditional machining cannot easily achieve, which improves cooling efficiency during the injection molding process.

This faster and more uniform cooling reduces cycle times, increases throughput, and improves part quality by minimizing warping and defects. Using 3D-printed molds helps optimize cash flow, accelerate product development, and support more agile production, giving you a competitive edge while reducing operational costs in your injection molding projects.

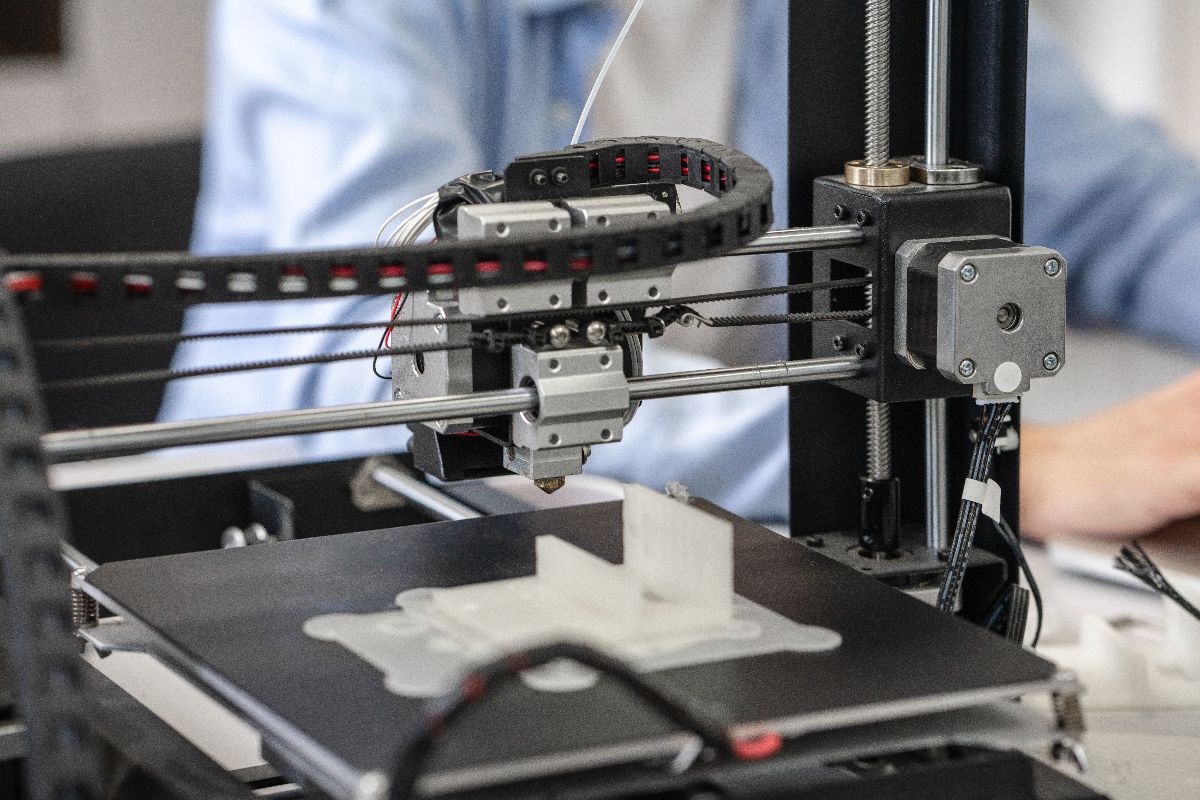

Conformal cooling channel inserts are one of the most valuable ways to use 3D printing in injection molding because they allow you to significantly improve cooling efficiency during production. Traditional straight-line cooling channels created through CNC machining often cannot closely follow the complex geometry of a mold cavity, leading to uneven cooling and longer cycle times.

Conformal cooling channels, however, are designed to “conform” to the shape of the mold, following the contours of the cavity and core more closely. Using conformal cooling channel inserts helps you reduce cycle times, improve part quality, and extend mold life.

Faster and more uniform cooling reduces the risk of warping, sink marks, and internal stresses in your injection-molded parts, ensuring dimensional accuracy and a better surface finish. This means more parts are produced in less time without sacrificing quality, ultimately lowering production costs and increasing throughput.

Creating essential auxiliary tools used in injection molding, such as jigs, fixtures, grippers, and end-of-arm tooling for robotic systems, plays a critical role in supporting tasks like precise part placement, trimming, and efficient removal of parts from molds.

These components ensure a smooth and consistent workflow throughout the injection molding process. Traditionally, manufacturing such tooling relies on CNC machining and manual methods, which can be time-consuming, expensive, and less adaptable to design changes or replacements.

Using 3D printing for tooling component fabrication in injection molding allows you to quickly produce custom-fit components tailored to your specific production requirements. It enables the creation of lightweight yet durable fixtures and grippers with complex geometries that are difficult or expensive to achieve with conventional methods.

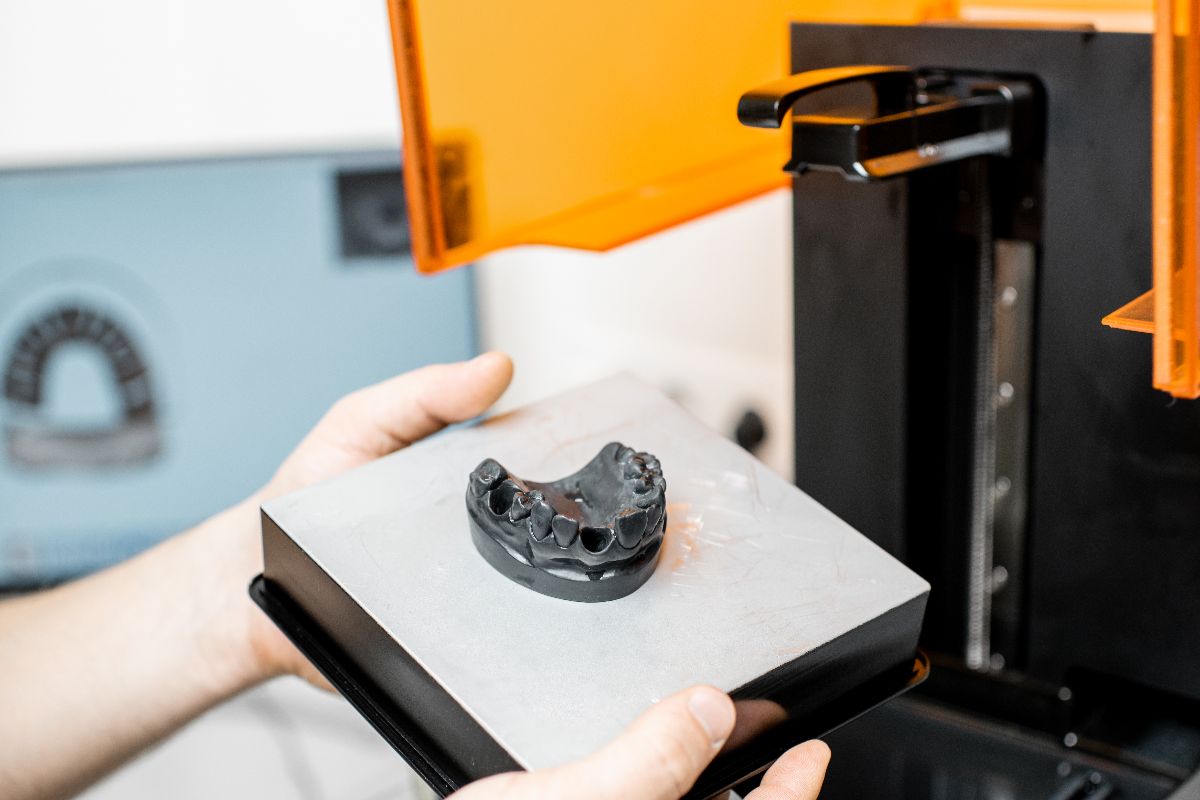

One of the most practical ways to use 3D printing in injection molding is Mold repair and modification, because it allows you to address damage or design changes in your molds quickly without incurring the long lead times and high costs associated with traditional machining.

Over time, molds can experience wear, cracks, or surface damage due to high-pressure cycles, which can halt production or affect part quality. With 3D printing, you can rapidly produce precise inserts or replacement components to repair these molds, restoring them to working condition without waiting for conventional tooling repairs that often require disassembly, shipping, and extended downtime.

3D printing also offers the flexibility to modify your existing molds to accommodate new design features or product updates without the need to produce entirely new tooling. For example, if your customer requests a small design change or if you need to add a logo or functional feature, you can 3D print inserts that fit into your current mold, enabling you to update your tooling efficiently.

Understanding how to use 3D printing in injection molding can transform your production approach, helping you reduce tooling lead times, accelerate prototyping, and enhance mold functionality with advanced design features. From producing rapid prototypes to creating conformal cooling channels and enabling quick mold repairs, 3D printing integrates seamlessly into injection molding workflows, offering flexibility and efficiency without compromising quality.

At Richfields, we specialize in precision plastic injection molding and large-part production, supporting businesses globally with reliable, high-quality solutions. If you’re looking to enhance your injection molding projects, contact us today to learn how we can help you achieve faster, more cost-effective production while meeting your exact requirements.