3D printing vs injection molding. What are the differences between them? Which one is better? To start off, 3D printing is more portable, while injection molding is industrial-sized. 3D printing is best for producing smaller parts, while injection molding can handle all sizes. On the other hand, injection molding is more cost-effective than 3D printing. Injection molding also produces better products compared to 3D printing.

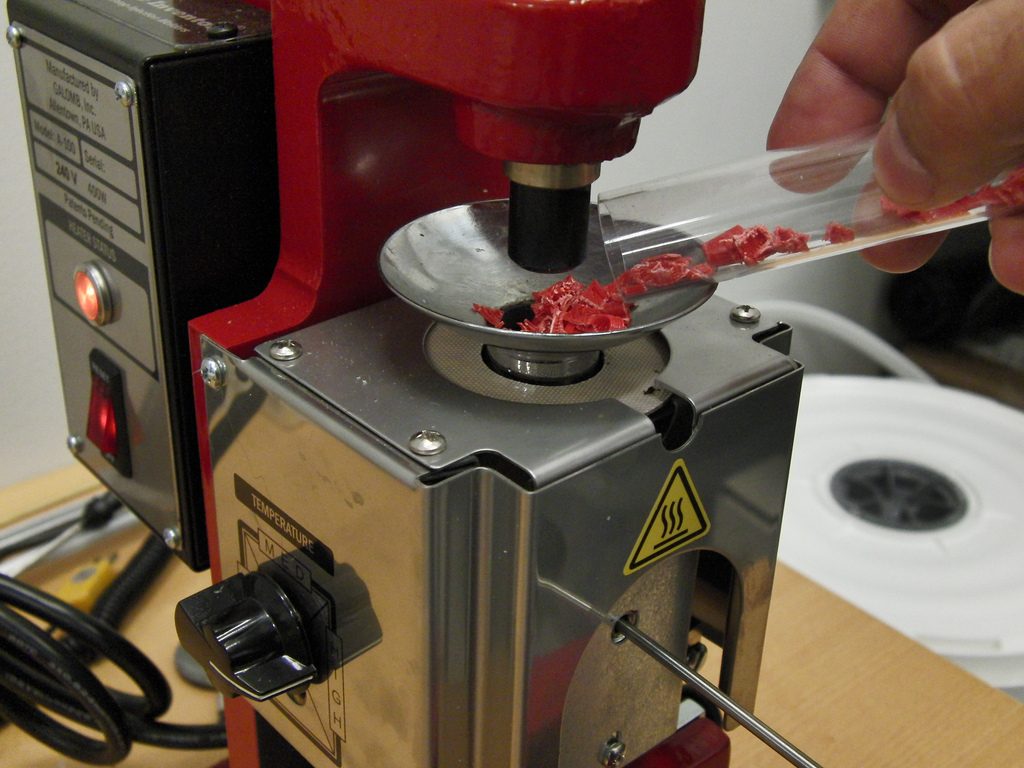

Injection molding is a large industry that is one of the world’s most profitable. In fact, injection molds in China are some of the largest and most successful, being able to bring in a great number of products in a short amount of time. This helps address the massive demand for plastic products all over the world.

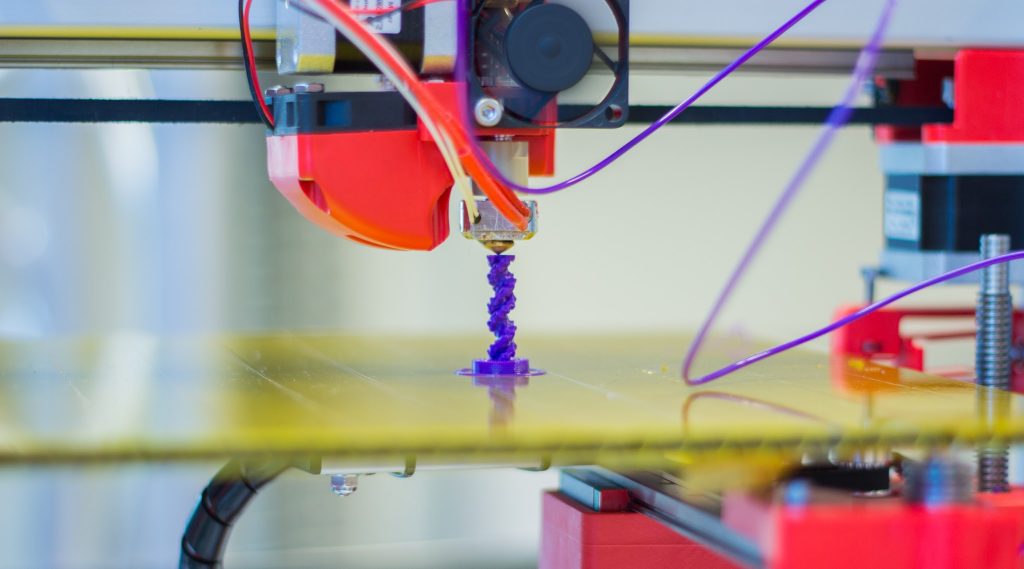

Plastic can be produced using an injection molding machine, which helps make the overall production fast and efficient. But in the past few years, a new process called 3D Printing was introduced, which has become a popular way of manufacturing plastic as well.

People have been wondering what are the differences between the two, and which one is more efficient than the other. In the effort to help clear the issue up, we listed down the important things that you should know about the two.

3D Printing is more portable, while injection molding is industrial-sized

One of the reasons why many people look into 3D printing as a processing method is that the machines are smaller compared to the industrial-sized injection molding machines. This helps them produce products in any location they choose. Meanwhile, injection molding machines would have to be moved by large vehicles for it to be transferred to the proper facilities.

3D printing is best for smaller parts, while injection molding can handle all

Since 3D printing is more portable, they are more suited when it comes to producing smaller parts. Meanwhile, injection molding machines can produce plastic products of any size. The size of the product would only be limited to the size of the mold, which makes the injection molding a very versatile production method.

Cost effectiveness

Most people say that 3D printing is the more affordable alternative to injection molding, which may seem the case at a glance. The cost to produce a 3D printed plastic product, along with the molds, labor, and maintenance, is quite lower than injection molding, but you will not be able to produce as much products.

Meanwhile, injection molding would allow you to produce a large number of products in a short amount of time. When it comes to the molds, 3D printing uses molds that deteriorate over time, while injection molding can use the same molds over and over again, making it more cost efficient.

Overall product quality

In the end, it would all come down on which manufacturing process would produce a quality product. A product that is produced from 3D printing is mostly rough around the edges, needing more refinements before becoming a finished product. On the other hand, injection molding produces products that only need to have minor refinements, and therefore can be distributed immediately, ensuring that you have a quality product.

Key Takeaway

When you are producing plastic products, you will need the right balance between quality and efficiency. Overall, injection molding machines are able to produce better results and can do so repeatedly. It is also cost-effective, making sure that you get the best value out of your products while also making full use of the plastic material.