Best Rapid Prototyping Services In China

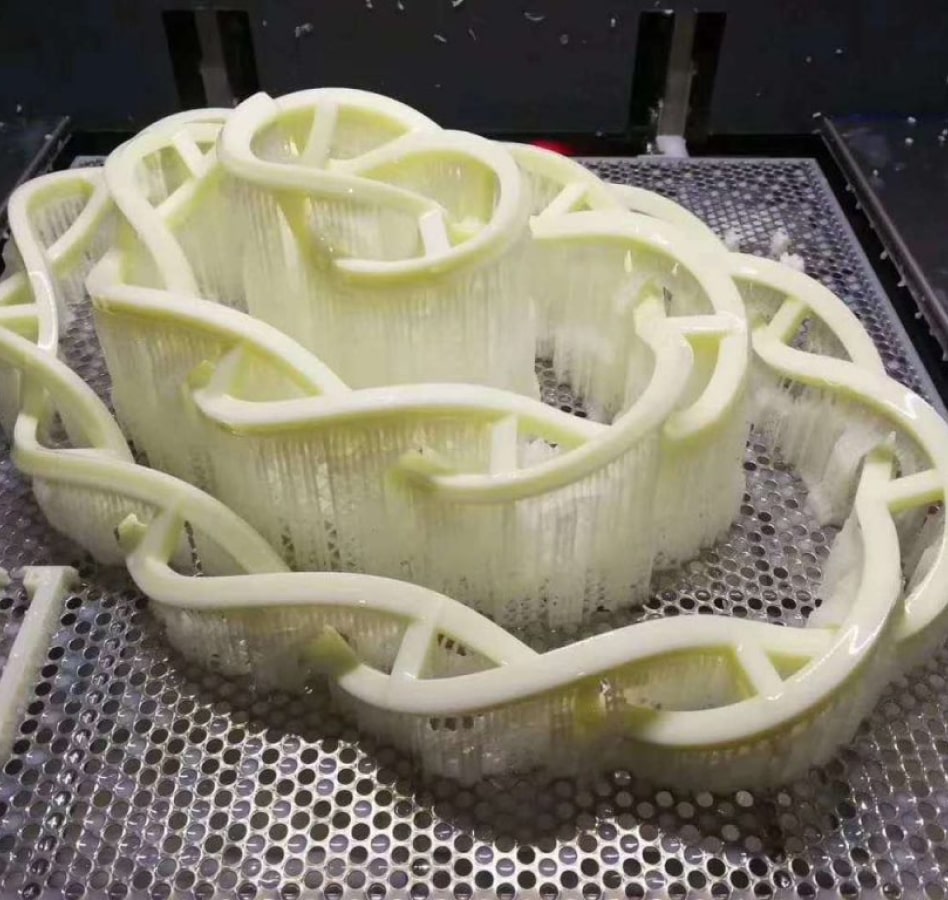

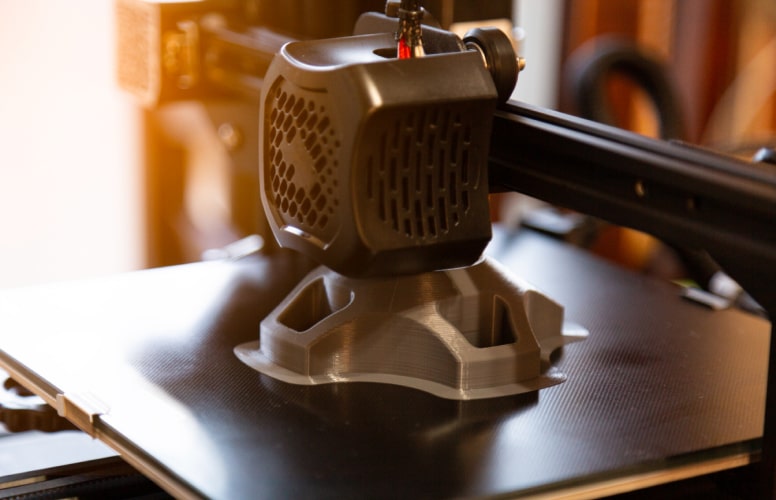

If you’re looking for rapid prototyping services in China, then you’re definitely in good hands with Richfields. Our plastic prototyping services are a low-cost method of providing form and function to your design ideas. Primary processes in tool manufacturing can be quite expensive — it’s important that you’re first given a concrete idea of what your product may look like and how it will function.

Our rapid prototyping services in China are designed to make it easier for you to determine if there are any modifications that you want to make on your product. Likewise, hiring professional prototyping services also help you identify how well your product can hold up when it reaches the end-user. Find out why our prototyping services are fit for a wide range of applications by reading on.