Latest Blogs

Large Size Plastic Molding vs Traditional Metal Fabrication: What’s Best for Your Product?

Overview The decision between large-size plastic molding and traditional metal fabrication can significantly influence the manufacturing outcome of your product. It’s crucial to comprehend the distinct advantages and constraints of each method to identify the most suitable manufacturing solution tailored to your specific product requirements. Many companies favor large-size plastic molding because of its versatility, […]

Read more

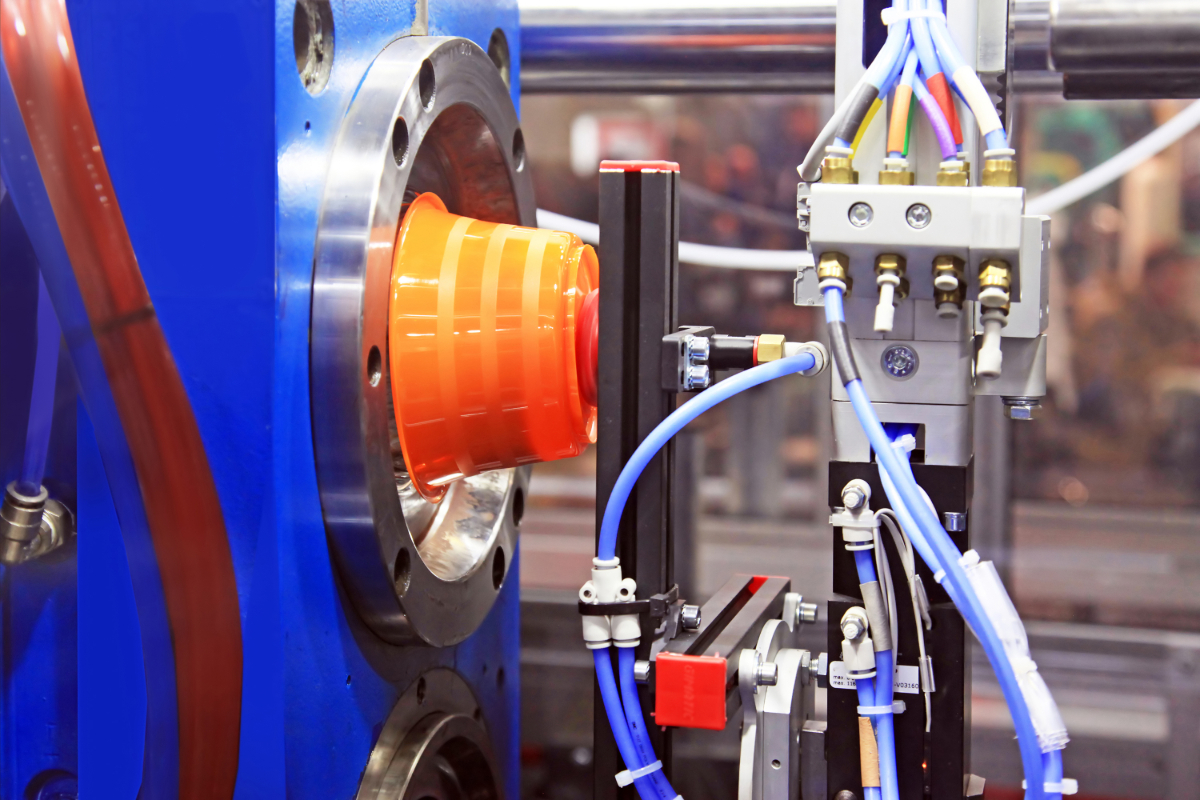

Key Considerations in Using Large-size Plastic Molding

What do you need to consider when using large-size plastic molding? Mold Design and Tooling Material Selection Equipment Capacity Molding Process Optimization Quality Control Measures Cost and Lead Time Overview Large-scale plastic molding encompasses various critical factors that require careful consideration to achieve successful results. Addressing these factors allows manufacturers to uphold competitiveness in the […]

Read more

Material Properties Crucial for Large-size Plastic Molding

What material characteristics are vital for molding large-size plastic? Melt Flow Index Melt Strength Impact Resistance Heat Deflection Temperature Shrinkage Thermal Conductivity Overview This article explores the crucial role of material properties in the success of large-size plastic molding, highlighting the importance of melt flow index, melt strength, impact resistance, heat deflection temperature, shrinkage, and […]

Read more

How is Plastic Injection Molding Used for Auto Interiors

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read moreOther Blogs

6 Plastic Medical Device Trends to Know for 2022

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more

6 Things to Consider Before Switching Plastic Injection Molding Materials

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more

4 Tips for Injection Mold Maintenance and How Your Injection Molding Partner Can Help

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more

Top 8 US Industries That Benefit From Injection Molding Services

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more

Plastic Injection Molding Quotes: 7 Things to Prepare

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more

6 US Injection Molding Industry Trends for 2022

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more

Best Practices for Better Injection Molding Tolerance

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more

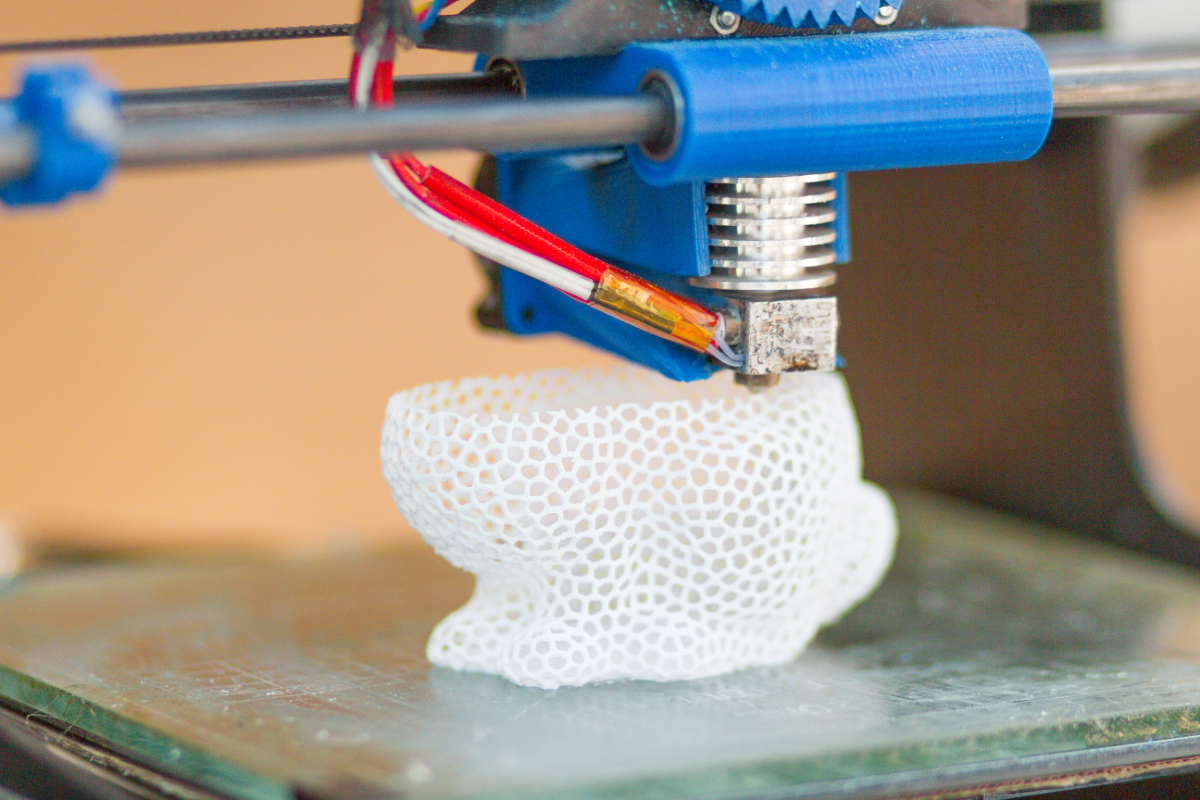

A How-To Guide to Creating Your First Custom Plastic Part

What are the different applications of plastic injection molding for auto interiors? Dashboard components Interior trim Seats Buttons, knobs, and controls Airbag components Storage compartments Overview Plastic injection molding revolutionizes automotive interiors, enabling the creation of intricate and durable components with precise designs. This process allows for diverse applications of vehicle interiors, such as dashboard […]

Read more