Why should solar panels have a plastic casing?

- It protects the panels from different weather conditions

- It prevents discoloration and warping

- It can be molded into different shapes and sizes

- It reduces its carbon footprint

- It helps reduce the manufacturing costs of solar panels

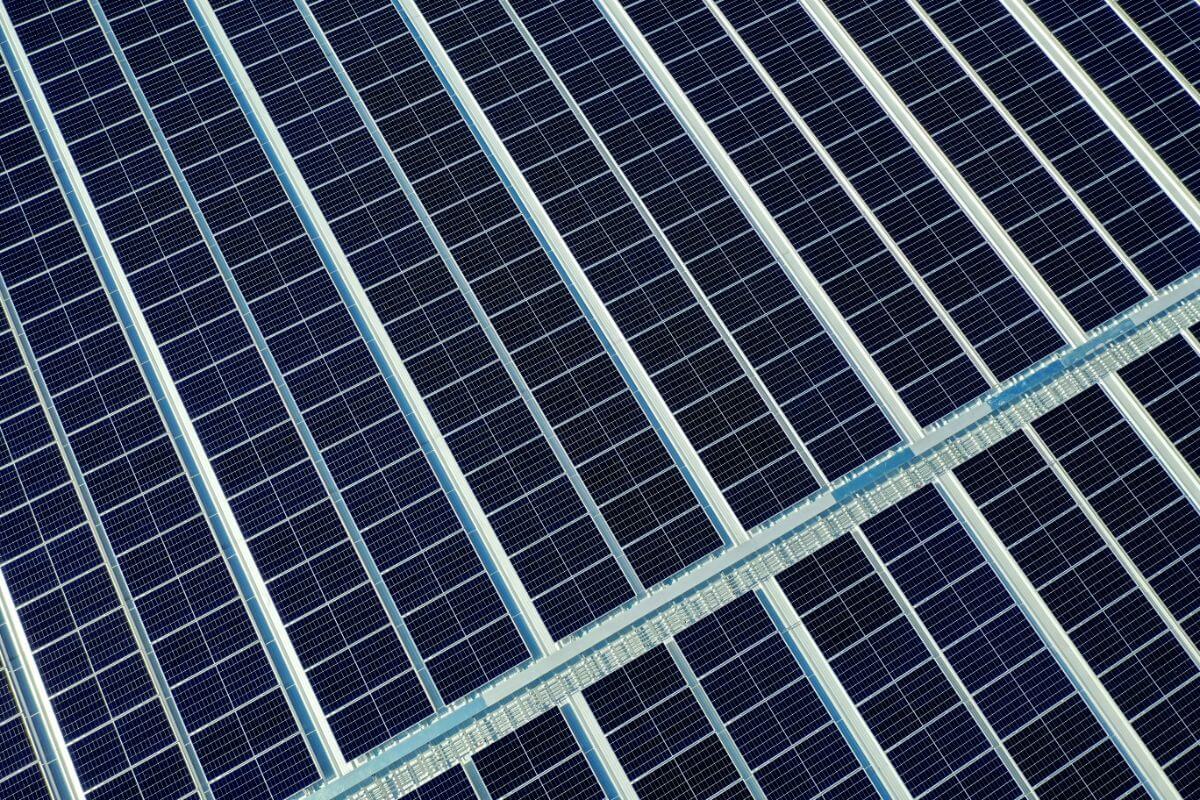

Solar panels are becoming more popular as a source of renewable energy. As the demand for solar panels increases, it’s only important to ensure that they are not only energy and environmentally efficient but also durable and safe to use.

One way to achieve this is by using a plastic casing for solar panels. In this blog post, we will uncover the reasons why should solar panels have a plastic casing, and how it benefits the overall performance of solar panels.

It Protects the Panels from Different Weather Conditions

A plastic casing protects panels from various weather conditions. It acts as a barrier between the panels and the environment. For instance, it shields the panels from moisture, rain, snow, and dust, which could damage the delicate components of the solar cells. Not to mention that it also provides UV protection from too much heat.

Remember, when the temperature rises above 25 degrees Celsius, the efficiency of solar panels begins to decrease by 10-25%. This is because a high temperature can cause an increase in the resistance of the electrical pathways within the solar cells, leading to a reduction in power output.

Therefore, the need to use a plastic casing is important because it regulates the temperature of the panels, which prevents them from overheating, freezing, and more.

It Prevents Discoloration and Warping

The optimal performance of solar panels relies on their ability to efficiently convert sunlight into electricity. Discoloration or warping of solar panels can negatively impact this process. Discoloration reduces the panels’ ability to absorb sunlight, leading to a decreased energy output.

On the other hand, warping can result in an uneven surface that casts shadows on the solar cells, reducing the amount of sunlight they receive and, consequently, the amount of energy they produce. Therefore, it is crucial to keep your solar panels in good condition to ensure their maximum efficiency.

Solar panels with plastic casings are on the rise. It’s because their thickness can cover the panels. However, it’s recommended that the plastic casing should be 4mm thick to allow the highest amount of energy collection of solar panels from the sunlight – without too much exposure to high heat.

This way, they prevent solar panels from discoloration and warping since they provide a layer of insulation, which prevents the panels from receiving too much heat.

It Can Be Molded into Different Shapes and Sizes

The plastic casing used in solar panels is often made of polycarbonate, a transparent plastic material that offers chemical resistance, which makes it a great alternative to glass in the production of solar panels.

Polycarbonate is incredibly durable and able to withstand various weather conditions, such as storms, snow, and even accidental impacts. It has 200 times better impact resistance than glass, making it a stronger material. In addition to this, it’s also light in weight, which makes it easier to mold into different shapes and sizes for the panel’s plastic casing.

On top of that, it has the ability to resist yellowing and maintain the color clarity of panels over time. When using polycarbonate as a plastic casing, it also offers light transmittance from 88-90&, which allows for optimal sunlight absorption by the solar cells.

It Reduces its Carbon Footprint

The use of plastic casings, particularly those made of polycarbonate, in solar panels can help reduce their carbon footprint. As mentioned earlier, polycarbonate is lightweight, durable, and can withstand high temperatures, which means they’re only using fewer fuel fossils during the transportation to the market or consumer’s house.

Additionally, plastic casings are mostly recyclable, so the waste produced during the manufacturing process can be reused, reducing the amount of plastic waste that ends up in landfills.

It Helps Reduce the Manufacturing Costs of Solar Panels

The aforementioned benefits of using plastic casings are the reasons why it’s less expensive than traditional metal casings. It’s due to the fact that the properties of plastic like polycarbonate make them easy to design, transport, install, and maintain. As a result, they reduce the need for replacement, making them more affordable than other solar panel casings.

Key Takeaway

We’ve just answered why should solar panels have a plastic casing. Solar panels require a protective casing. Therefore, it’s important to use a plastic material like polycarbonate for their casing to shield them from extreme weather conditions, discoloration, and warping, and reduce their carbon footprint in the environment.

If you’re looking for reliable plastic injection molding in the USA, look no further than Richfields Corporation! We provide high-quality injection molding services for products that require the use of plastics or resins.

With the help of our complete and top-notch injection molding tools, equipment, and licensed engineers, we can mold your plastic products based on your desired results.

Contact Richfields Corporation here for more information or inquiries.