Why should plastics be used for battery casing?

- Lightweight and durable

- Chemical resistance

- Design flexibility

- Electrical insulation

- Cost-effective production

- Environmental considerations

- Customization

Overview

Plastics are a popular option for battery casings because of their lightweight nature, exceptional durability, and resistance to chemicals.

They provide flexibility, electrical insulation, and cost-effective manufacturing, all while staying in line with environmental concerns.

The customizable features allow manufacturers to craft battery casings that are precisely tailored to their specific products.

Batteries are an integral and often underappreciated component of our daily lives. Regardless of whether it’s the battery fueling your smartphone, automotive vehicles, or renewable energy setup, the protective housing surrounding these power sources holds significant importance. When discussing battery casings, plastics emerge as a preferred material for a wide array of reasons.

In this article, we will dive into why plastics should be used for battery casings, including their lightweight and robust qualities, resistance to chemicals, adaptability in design, electrical insulating properties, cost-efficient manufacturing, eco-friendliness, and customization options.

Lightweight and Durable

Battery casings need to find a balance between durability and weight. Plastics, with an impressive strength-to-weight ratio, shine in this aspect. They provide the required toughness to safeguard batteries while ensuring the device’s overall weight remains manageable.

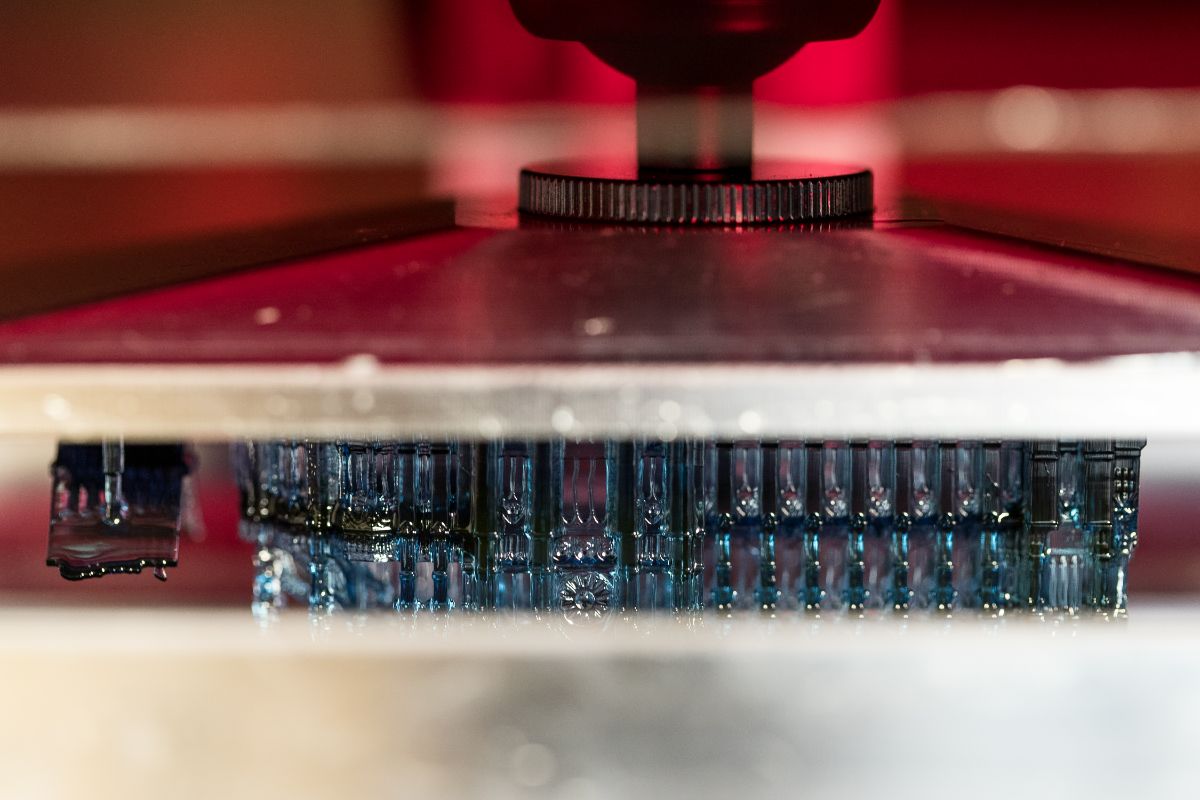

Plastic injection molding, a highly versatile manufacturing process, is instrumental in achieving this delicate balance. Injection molding techniques enable precise control over the design and manufacturing of battery casings, ensuring they meet the stringent criteria for strength, weight, and durability.

Chemical Resistance

Batteries create and store energy by undergoing chemical reactions. This implies that they might encounter a range of chemicals and substances throughout their lifetime. Plastics like Polypropylene and Polyethylene demonstrate remarkable resistance to chemicals.

These materials function as a safeguard, guarding the inner workings of the battery from external factors, guaranteeing the secure and dependable functionality of the device, even when it is exposed to potentially corrosive chemicals and substances.

Design Flexibility

Plastics offer a key benefit in their flexibility, which is highly advantageous. For instance, consider the scenario of designing a sleek, high-tech smartwatch. The battery casings for these devices are available in a wide range of shapes and sizes, each meticulously tailored to meet the unique needs of the watch they encase.

They can be shaped into almost any desired form, enabling the creation of intricate and personalized designs. This adaptability is especially valuable in situations where there is limited space and a custom casing is necessary.

Electrical Insulation

Apart from safeguarding the battery physically, battery casings should also ensure electrical insulation. Plastics, being inherently non-conductive, emerge as a great option to prevent electrical shorts and maintain the battery’s internal connections intact.

A case in point is a state-of-the-art, compact electronic medical apparatus employed in remote healthcare scenarios. It’s essential that this device’s battery casing not only fits perfectly within its limited space but also guarantees absolute electrical insulation.

Cost-Effective Production

Manufacturers continuously strive to find economical alternatives while upholding high-quality standards. Plastics, due to their straightforward manufacturing process and widespread availability, present a budget-friendly choice for creating battery casings.

This results in batteries that are more reasonably priced, thereby enhancing the affordability of electric vehicles and renewable energy systems. Consequently, it encourages the acceptance of environmentally friendly transportation options and plays a role in promoting a sustainable future.

Environmental Considerations

Sustainability is a pressing concern in today’s world. One way to address this is by recycling and repurposing plastics for battery casings, which can significantly mitigate the environmental footprint of battery production. Additionally, plastic materials’ durability extends the lifespan of battery casings, reducing the need for replacements.

By choosing cost-effective plastic battery casings, electric vehicle manufacturers can lower vehicle costs, driving consumer accessibility, leading to reduced greenhouse gas emissions and decreased reliance on fossil fuels.

Customization

Battery casings frequently have to adhere to particular standards depending on the intended use of the device. The use of plastics provides the flexibility to personalize elements such as color, dimensions, form, and even branding.

As an illustration, a producer of premium smartphones can personalize the battery casing to merge with the device’s branding, resulting in a unified and aesthetically pleasing end product.

Key Takeaway

The reason why plastics should be used for battery casings is that they offer lightweight durability and chemical resistance through processes like injection molding. They ensure electrical insulation and cost-effective production, contributing to affordable electric vehicles and sustainable energy solutions.

Environmentally conscious practices, such as recycling, further reduce their ecological impact, and customization options enhance their appeal for premium device casings, promoting both innovation and sustainability.

When it comes to discovering the perfect solution for your battery casing needs, Richfields Corporation is your trusted choice. With over two decades of experience in Custom Injection Molding, we excel in delivering precision, efficiency, and groundbreaking innovation in crafting top-notch plastic components. Contact Richfields Corporation for more information.