Overview

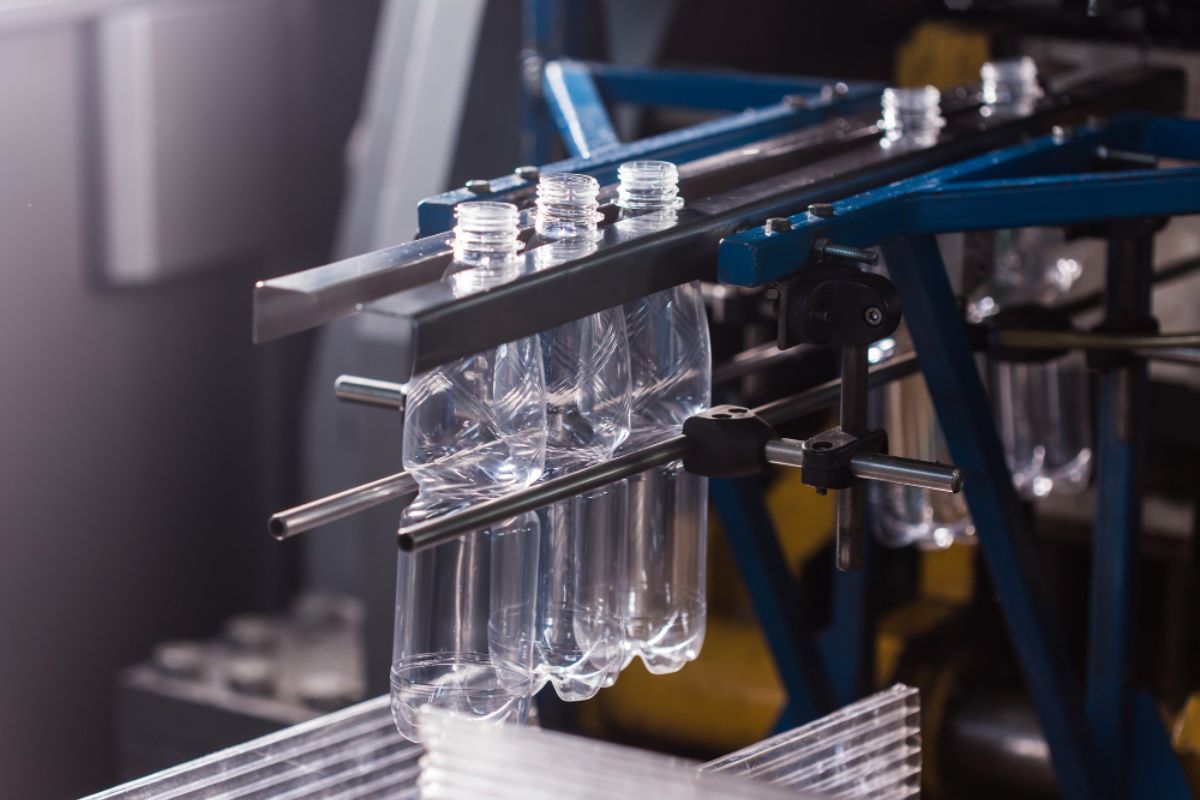

- Outsourcing plastic molds offers access to specialized expertise, cost savings, scalable production, and strict quality standards.

- It’s a strategic solution for companies aiming to reduce costs, accelerate production timelines, and maintain high-quality output in competitive markets.

The precision and durability of your plastic molds directly impact product quality, production efficiency, and long-term costs. As businesses face increasing pressure to optimize operations and shorten lead times, many are turning to global mold-making partners to stay competitive.

That’s why, in this article, we’ll explore the key reasons companies choose to outsource their mold-making needs, along with the benefits of working with reliable, export-focused manufacturers. Whether you’re scaling production or bringing a new product to market, the right tooling partner can significantly enhance your operational success.

Why Outsourcing Plastic Molds Makes Sense?

Outsourcing plastic molds has become a smart, strategic choice for manufacturers looking to balance cost, quality, and efficiency. It’s not just about saving money—it’s about gaining access to specialized expertise, scalable production, and globally recognized quality standards that support long-term success.

Access to Specialized Expertise

Offshore mold makers, particularly those with export experience, often serve a wide range of industries—from automotive and medical devices to consumer goods and electronics.

This cross-industry exposure equips them with deep knowledge of complex mold designs, material behaviors, and production challenges. They understand how different resins flow, how part geometry impacts cooling, and how to optimize molds for durability and performance.

These mold makers are also well-versed in design-for-manufacturing (DFM) principles. They can collaborate with clients early in the design process to suggest modifications that reduce production risks, improve part quality, and extend mold lifespan.

Significant Cost Advantages

Manufacturers in regions like China benefit from lower labor costs and more efficient operational expenses, allowing them to offer highly competitive pricing without compromising quality.

Beyond basic labor savings, established mold makers optimize processes to reduce material waste, improve machining efficiency, and shorten production times. This leads to further cost reductions over the lifecycle of the mold.

For businesses, these savings can be reinvested into product development, marketing, or expanding production capacity. It’s not just about paying less—it’s about gaining more value for every dollar spent on tooling.

Scalable Manufacturing and Faster Turnarounds

Global mold makers are built for scalability. Their facilities are often designed to handle everything from single-cavity prototype molds to multi-cavity, high-volume production molds. This flexibility allows companies to scale manufacturing based on demand without delays.

In-house capabilities such as CNC machining, EDM (Electrical Discharge Machining), mold testing, and adjustments, for instance, reduce the time needed to complete tooling projects.

This level of speed and flexibility is essential for businesses bringing new products to market or responding to changing customer demands. Faster tooling lead times translate to faster product launches and improved market competitiveness.

Quality Standards and Certifications

Quality is a top priority when outsourcing molds, and reputable mold makers meet or exceed global quality standards. Many hold ISO certifications and comply with industry-specific regulations like RoHS, CE, and FDA requirements, depending on the product’s application.

Experienced mold makers also understand that the longevity and performance of a mold directly impact production reliability. As a result, they prioritize tool steel selection, proper heat treatment, and precise machining to deliver molds built for durability.

Where to Find the Best Plastic Molders in China?

China remains a leading hub for plastic mold manufacturing, offering a strong combination of technical expertise, cost efficiency, and advanced production capabilities. The key is finding a mold maker with proven experience in export-quality tooling, who understands international standards and the demands of global manufacturing.

At Richfields, we’ve built our reputation as one of China’s trusted plastic mold manufacturers, serving clients worldwide with precision tooling and export-quality molds. With decades of experience, we understand the requirements of international markets and deliver molds that meet strict quality standards across various industries.

We take pride in offering not just molds but manufacturing solutions that help our clients improve efficiency, reduce costs, and maintain consistent product quality. Whether you need complex molds for automotive parts, consumer products, or medical components, Richfields is ready to support your manufacturing goals.

Key Takeaway

Understanding why outsourcing plastic molds makes sense is crucial for businesses looking to improve production efficiency, control costs, and maintain high-quality standards.

So, if you’re looking for a reliable manufacturing partner to help bring your products to life with precision and efficiency, Richfields has got you covered. Contact our team today to discuss your next tooling project.