June 11, 2019

The Guide to Repairing Plastic Parts

Plastic is one of the most versatile and durable materials around. However, plastic can also break, and at times, it can be a real challenge to repair them without the right tools and methods. Whether it be plastic from a molding company in China or plastic manufactured from Europe or North America, any type of plastic is susceptible to breakage.

This is why using the right tools, and applying the correct methods, would be able to provide you with the best way to repair your plastic products, and make them usable again. Here’s an important guide on how to repair various plastic products and parts.

Perhaps the most common method of repairing plastic parts and products, glue and cement are also used when it comes to assembling various parts. Using glue is the most straightforward approach, as you would only need to apply glue to the broken area, and reattach the part accordingly.

It is important to note that certain types of glue and cement work on specific kinds of plastic, and using the incorrect one may cause your part to break off once more. Super glue and glue guns are effective for a lot of simple plastic repairs, as the glue can bind the parts together again for a long period of time before getting repaired again.

Plastic cement is similar to glue in the purpose of repairing plastic parts. But instead of applying a solution that sticks parts together, it instead softens and melts parts in order to be able to reattach them again. Another approach that has helped repair plastic parts using cement is putting plastic scrap into the cement to melt and create a putty-like mixture that can be used to reattach plastic parts together.

This approach is also common in repairing or assembling plastic model kits and is seen as one of the most efficient plastic repair methods around. Glue and plastic cement is also one of the safest repair methods around, as you would not have to deal with heating plastic.

Commonly used in boats like kayaks, along with plastic barrels or tubs, plastic patches act somewhat like a bandage that can cover a surface that has holes or cracks. Using plastic patches requires one to heat the patches in order to soften them up for application. Once applied, it only needs time to cool down to stick on the broken surface, and the repair is done. It is worth noting that this method uses heating materials that can be dangerous if not used properly and that the same kind of plastic must be used to ensure that the patch would stick more effectively.

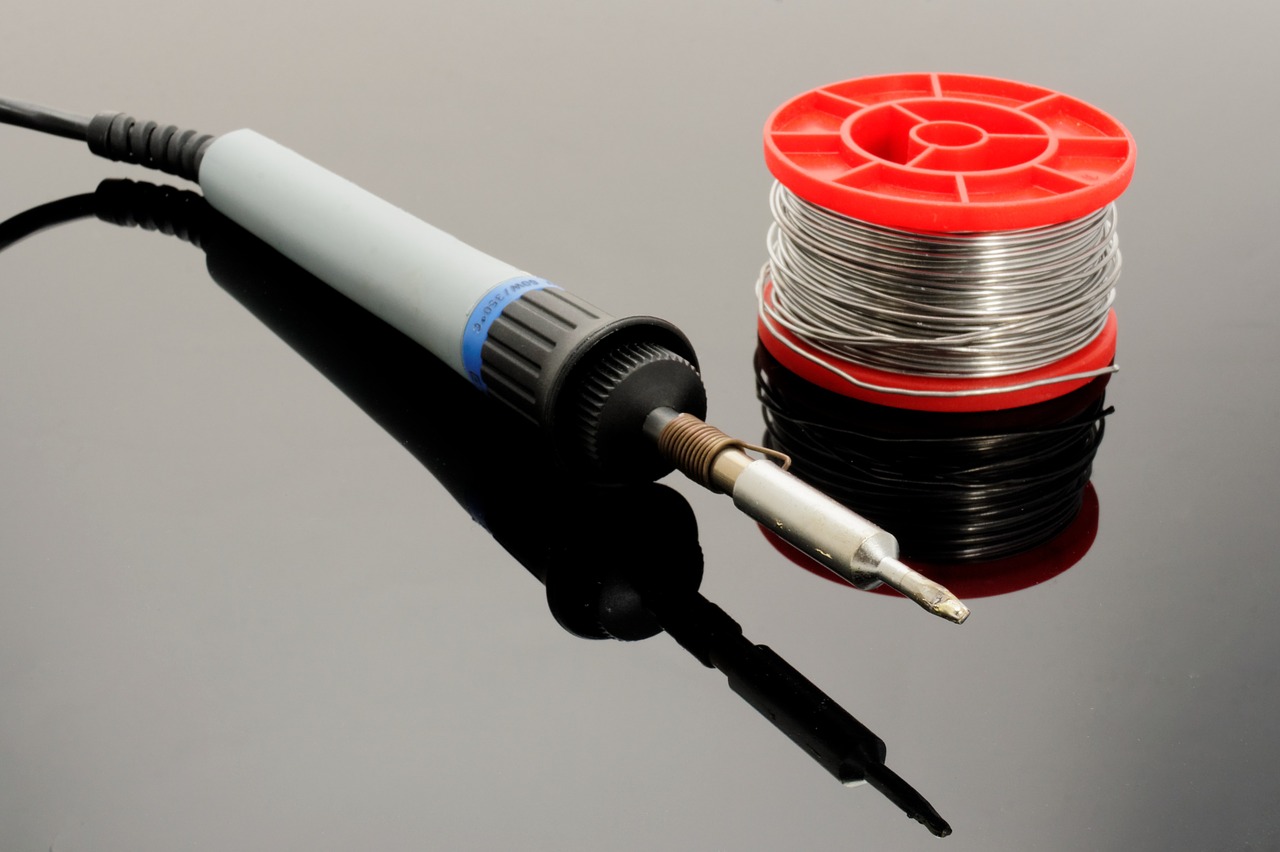

Another highly effective repair method, plastic welding involves using a soldering iron to repair plastic parts together. Like plastic cement, plastic welding involves melting broken plastic parts together in order to put them back. Alternatively, plastic scrap can also be used to be melted along with the plastic parts. Plastic welding utilizes a soldering iron that is set at a low-temperature setting to melt the parts.

After welding the plastic parts together, the next step is to use sandpaper to smoothen up the surface of the welded plastic. Sanding the part requires a number of sandpaper grit levels in order to polish it to the smoothest surface. Plastic welding is used for a wide variety of repair projects, such as automotive repair where larger parts are involved. This is also one of the most effective long-term repair solutions, as plastic welding can restore the durability of the plastic part.

It is worth noting that this method requires a number of safety steps and equipment, as melted plastic can release fumes that can be harmful when inhaled. Gloves are also required, as you would be dealing with high temperatures that can damage your skin. Safety precautions that a plastic molding company from China or elsewhere adheres to must always be followed.

Used to repair a number of plastic figures, putting a plastic part or figure in hot water allows you to soften up the plastic in order to repair them. In order to prepare the repair procedure, heat up water to almost boiling temperature. The next step is to put the plastic parts into the water.

The softening process can take a few seconds to minutes depending on the type of plastic used. Once the part has been softened up, you can now move around the softened part and fix the broken area. Once the part has been moved, place the part in cold water in order to return to its solid state. While this method is not applicable to all kinds of plastic, it is an efficient method of repairing without having to melt and glue together parts.

Plastic repair can be done in a wide variety of methods, each being able to restore the durability of parts to make them useable again. With these efficient and effective plastic repair methods, you would be able to repair broken plastic parts from the comfort of your own home with just the right tools.