Plastic injection molding in China can be used effectively to make life easier. It essentially contributes to the ease of use and accessibility of the product. The range of uses of these plastic injection molded items can range from every day to specialty needs. If you look at the majority of your household items, most are made from plastic injection molding. It can be a component of your car, the lid of your bottle or toys for your kids.

People have been molding objects for ages. They first started off using clay, sand, and mud. Plastic came from the Greek word “plastikos” which means “moldable”. To replace ivory billiard balls, John Hyatt patented a method using celluloid to replace the ivory. He was the first to use hot celluloid in a mold in 1872. Along with his brother Isaiah, they patented an injection molding machine that utilized a plunger to inject plastic through a heated cylinder, which then goes into a mold. Buttons and hair combs were some of the first products created with this revolutionary method. It wasn’t until World War II that the plastic injection molding industry really kicked off. James Hendry built the first screw injection molding machine and changed plastic injection molding methods.

If you look closer at what we have today, there are many industries that heavily utilize plastic for their products. By adding fillers and components to change the chemical structure of the resin, each product that’s manufactured has its own special standout properties. Let’s look closer at how you can use plastic injection molding items effectively for different sectors.

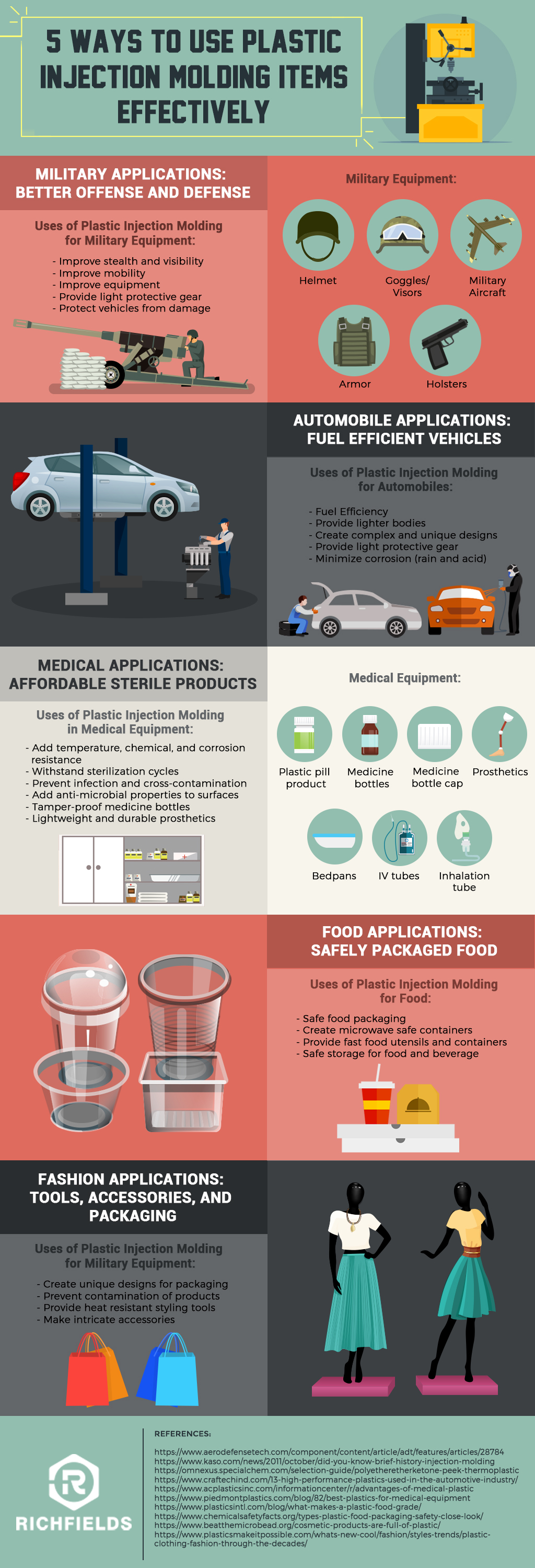

Military Applications: Better Offense and Defense

As mentioned earlier, the military has effectively utilized plastic injection molding. In particular, American Soldiers carry tons of equipment and protective gear that’s usually made of synthetic materials such as plastic. Before innovating plastic in their equipment, military equipment consisted of metal. Weaponry and chainmail offered offense and defense, but the trade-off was the weight of the material. Plastics offer a better weight. They are light and are better choices for armor, clothing, protective gear, and vehicles. Weight changes the dynamic of the soldier, making them more agile.

Plastic injection molding in China can offer greater freedom when it comes to the design of military equipment. More parts can be created and combined into one convenient mold. Assembling equipment is easier with plastic injection molding. Additives can be added to the resin during the process to enhance durability. Soldiers are subject to multiple challenging situations that require impact, heat, chemical, and moisture resistance.

The end of each equipment used is also important. This can be a crucial factor for the visibility of the soldier when it comes to camouflage and stealth. With plastic injection molding, there’s no need to do an extra coating or paint job. Manufacturers can easily design and modify the color or finish of the equipment that can result in a robust but quick output.

Even if you look at the military industries in other countries as a thriving market, it can still be very expensive to manufacture equipment. These can go through significant wear and tear faster. Equipment can be lost or damaged during operations. Replacements and upgrades should be easily accessible so that soldiers can fulfill their duties safely and efficiently.

The go-to plastic used for various equipment is polydicyclopentadiene or simply pDCPD which is a high tensile strength polymer. This polymer has a high impact resistance and corrosion resistance. The other benefits of this polymer include resistance to melting and freezing plus it’s compatible with many temperatures.

pDCPD is used for:

- Body panels (for buses and trucks)

- Construction equipment

- Agricultural equipment

- Military equipment

- Water containers

Polyetheretherketone or PEEK is another polymer used in military applications, particularly for aircraft. It’s a high-performance engineering plastic with high-temperature resistance until 260 C. Heat resistance also provides significant protection from fire, which is great for the high stress induced in air crafts. It’s also highly resistant to chemicals. If combined with carbon fiber, the tensile strength increases exponentially.

PEEK properties:

- Low friction

- Superior dimensional stability

- Biocompatible

- Resistance to rain erosion

Uses of Plastic Injection Molding for Military Equipment:

- Improve stealth and visibility

- Improve mobility

- Improve equipment

- Provide light protective gear

- Protect vehicles from damage

Military Equipment:

- Helmets

- Goggles/Visors

- Military Aircraft

- Armor

- Holsters

Automobile Applications: Fuel Efficient Vehicles

Plastic injection molding in China continues to grow with each new vehicle designed by automobile manufacturers. More manufacturers and people are concerned with fuel efficiency. It’s a known fact that fossil fuels and gasoline are limited resources. In order to save more money on fuel, cars are being designed to have a lighter body to increase fuel efficiency. Engine responsiveness is the key to fuel efficiency and offering lightweight parts can decrease fuel emission.

Design is another concern for consumers. First impressions are often based on appearance and manufacturers are taking advantage of this. With plastic injection molding, complex and unique designs are easier to achieve.

Automobiles require high-performance plastics. Opting to use subpar materials can impact brand name automobile manufacturers and can put consumers in danger. Minimizing corrosion from external factors can prolong the life of your vehicle.

High-performance plastics with the right additives can create components with innovative design freedom. Below are some of the high-performance plastics that are used to create automobile parts and components.

- Polypropylene

- Polyurethane

- Poly Vinyl Chloride

- Acrylonitrile Butadiene Styrene

- Polyamide or Nylon

- Polystyrene

- Polyethylene

- Polycarbonate

- Acrylic

Uses of Plastic Injection Molding for Automobiles:

- Fuel Efficiency

- Provide lighter bodies

- Create complex and unique designs

- Minimize corrosion (Rain and acid)

Medical Applications: Affordable Sterile Products

Medical plastics have made healthcare significantly more affordable when it comes to equipment. What used to be just steel, glass, and ceramics is now medical grade plastics that are just as durable yet very cost effective. Medical grade refers to products that are sold under a physician’s license. A medical plastics manufacturer can have a medical director present to regulate and supervise the materials used to make the equipment.

Medical plastic is known to be temperature, corrosion and chemical resistant. The resistance is designed to ensure that it can withstand multiple sterilization cycles. It also has to withstand medical and bodily fluids that can be present at the time.

Plastic injection molding in China used for medical applications is very versatile. Medical plastic bedpans, inhalation tubes, and iv tubes have converted into using plastic as it’s readily available compared to other materials. To prevent the spread of infections, single-use surgical tools made from plastic are cost effective after every procedure. Anti-microbial properties can be embedded in plastic as well through the use of additives.

For medications to ensure the safety of consumers, caps are designed to be tamper proof. This ensures that the patient always gets a fresh batch of medication. Plastic containers that carry biodegradable materials can be shatterproof and permeable. For example, coolers that are designed for use in transporting organs and blood are more efficient in prolonging temperature than just using ordinary containers.

Amputees also benefit from medical grade plastic. Prosthetics are easier to develop with the help of injection molds. Prosthetics can be designed to be robust yet lightweight. It’s important for amputees to find a prosthetic that can withstand wear and tear. Here are some commonly used medical grade plastics.

Medical grade plastic:

- Acetal

- Polycarbonate

- Polyethylene Terephthalate Glycol (PETG)

- High-Density Polyethylene

- Polypropylene

Uses of Plastic Injection Molding in Medical Equipment:

- Add temperature, chemicals, and corrosion resistance

- Withstand sterilization cycles

- Prevent infection and cross-contamination

- Add anti-microbial properties to surfaces

- Tamper-proof medicine bottles

- Lightweight and durable prosthetics

Medical Equipment:

- Plastic pill product

- Medicine bottles

- Medicine bottle cap

- Prosthetics

- Bed pans

- IV tubes

- Inhalation tube

Food Applications: Safely Packaged Food

Food is another important industry that is dominated by plastic. Plastic injection molding in China can create food grade plastics that can serve as containers and packaging for food. There is a significant difference in plastics used in household items and plastic used for food. It starts off with the chemical components. Plastics are toxic but scientific innovations create plastics that can prevent these toxins from penetrating the food.

Food grade plastics can come into contact with food without compromising it. It can be used for harvesting, processing, and packaging the food. Below are some examples of food grade plastic.

Food Grade Plastic:

-

PET

Polyethylene terephthalate or PET is commonly used for bottles. Water bottles, soft drinks, and other beverages used PET because it’s lightweight and impact resistant. The contents of the bottle are protected from this.

-

High-density Polyethylene

HDPE is another food grade plastic that is very durable and lightweight. The characteristics of this plastic are its hardness and opaque nature. HDPE can be used for juice, milk syrup, and plastic grocery bags.

-

PVC

PVC is another common plastic that is resistant to biological and chemical factors. This can keep products from being tampered with. You can find PVC in the shrink wrapping and blister packaging used for gum and mint.

-

Low-density Polyethylene

LDPE is thinner but can still be heat resistant. Heat sealed packaging uses LDPE. Coffee lids, bread bags, and produce bags are commonly made from LDPE.

-

Polypropylene

PP compared to other plastics is stiff but brittle. Depending on the manufacturer, it can be opaque or transparent. The high melting point of PP is great for using in the microwave. You can find a lot of food items that use PP. Yogurt, cheese and cream containers use this plastic as its packaging.

-

Polystyrene

This plastic doesn’t offer much flexibility. PS can be used to make spoons and forks. Other products made from polystyrene include plastic cups, fast food containers, and hard cartons.

Uses of Plastic Injection Molding for Food:

- Safely packaged food

- Create microwave safe containers

- Provide fast food utensils and containers

- Safe storage for food and beverages

Fashion Applications: Tools, accessories, and packaging

Fashion and beauty greatly benefit from using plastic. Wholesale fashion accessories are cheaper if it’s made from plastic. Various components like buttons, hairstyling tools, and makeup brush ferrules are made from plastic injection molding in China. Hair styling tools can have additives that make it heat-resistant.

Fashion accessories such as earrings, bracelets, and watch straps can be created from an injection mold. Mass producing intricate designs for earrings and straps is much easier with injection molds. Even sunglasses and their lenses can be made from this process. Soles for shoes can be injection molded so that manufacturers can fabricate shoes quickly.

It starts off with obvious packaging. Purchasing combs or plastic brushes are usually packaged in a plastic component. With plastic injection molding, the packaging can make products very appealing and interesting. Premium products from luxury brands incorporate plastic. Perfume bottles may be made out of glass, but the caps can be from injection molding in order to incorporate intricate designs.

Uses of Plastic Injection Molding for Fashion and Beauty:

- Create unique designs for packaging

- Prevent contamination of products

- Provide heat resistant styling tools

- Make intricate accessories

Fashion accessories:

- Earrings

- Bracelets

- Watch Straps

- Belt buckles

- Belts

- Soles

- Rings

- Glasses

- Lenses

- Clips

Beauty Products:

- Combs

- Brushes

- Hair styling tools

- Makeup brushes

- Compacts

- Eye shadow packaging

- Jars

- Perfume bottles

- Bottle caps

- Lipstick packaging

- Deodorant packaging

- Lotion bottles

Use Your Plastic Injection Molded Items Effectively with Richfields

Plastic Injection Molding in China can be beneficial for you if you choose Richfields. Richfields Plastics is guaranteed to provide top-of-the-line products of the highest quality. Multiple investment groups in Hong Kong, along with skilled plastic manufacturing experts, collaborated with and founded Richfields Plastics in 2001. You’re guaranteed to get professional, high-quality service with competitive pricing for your plastic injection molding needs.

Choose from the wide variety of products by dropping by on this page. If you have more questions and inquiries, email us now, or contact us via phone or fax.