The manufacturing industry has remained as one of the world’s most active industries, with the mass production of goods and products operating daily. This is also an industry that has embraced the most innovations. Implementing new technologies and manufacturing methods that help make the overall process more efficient and reliable.

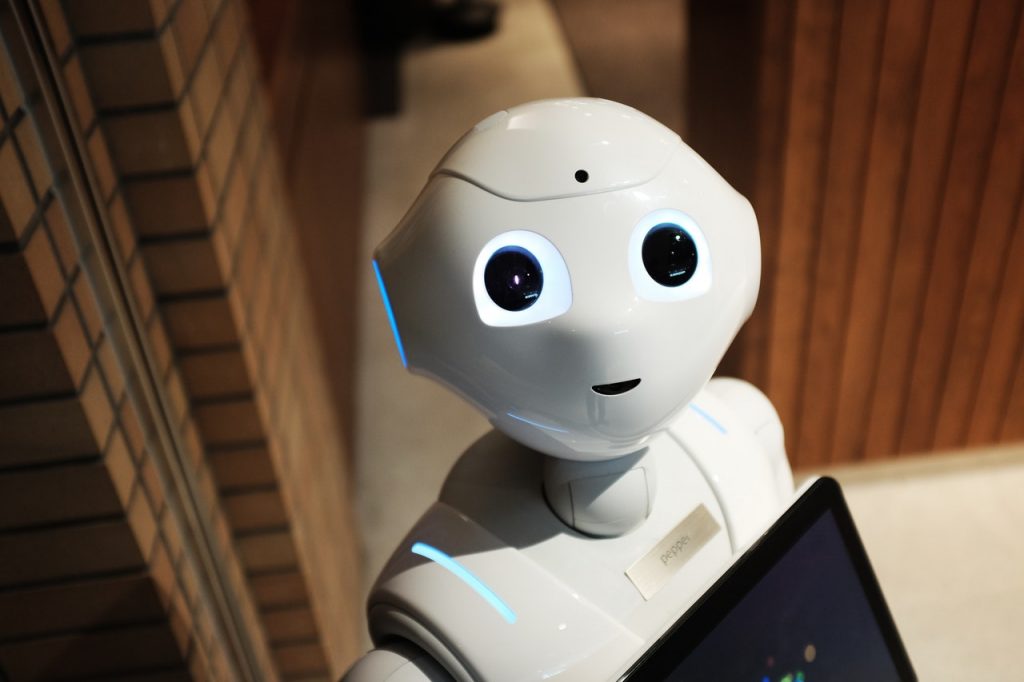

One of these innovations was the implementation of robotics, which has been introduced in enterprises like the plastic injection molding industry. The influx of these new machines has enabled companies to develop faster, safer, and more reliable manufacturing methods that can create high-quality products.

Robotics is a technology that has been developed over the past few decades and has now just recently become an important element to push the plastic injection molding industry forward. Along with helping the industry, plastic has also been utilized in different forms in the robotics industry, helping create crucial parts that help these machines work and operate.

Plastic in the Robotics Industry

Plastic has become one of the world’s most versatile materials. From being used to produce toys and simple tools, to becoming a crucial part in various types of robotic machines. Due to its light weight and high durability, plastic can be used to create different types of parts, such as creating outer shells that help cover and protect the exposed machinery, to becoming a part of a robot’s primary structure.

A notable example of plastic being used for robotics is the use of a plastic outer shell provided by Richfields to provide a protective cover for an AI-powered robot that is able to clean toilets in Singapore. Along with this robot, plastic parts have also been used for different types of robots, such as robots that utilize toy parts from Lego to robots that require light plastic shells to help them move around.

The Future of Robotics in the Plastic Injection Molding Industry

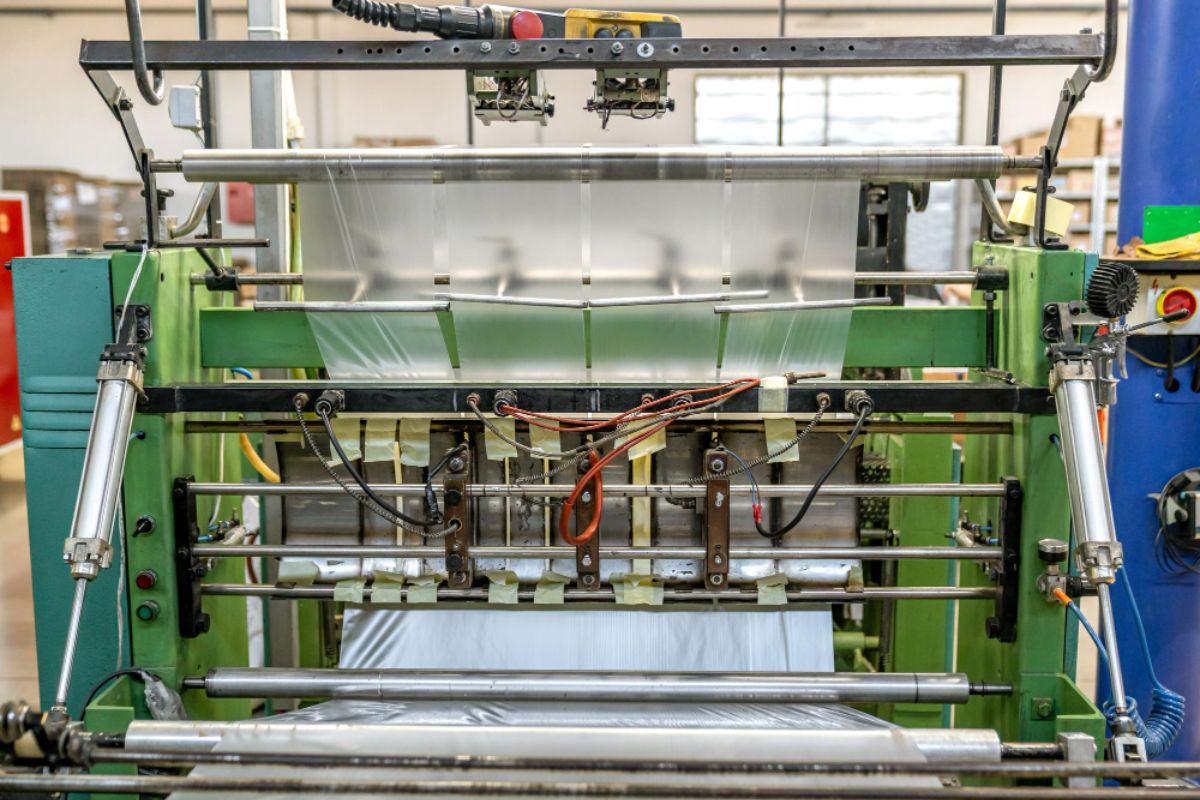

Robotics is a technology that has greatly improved over the years, and the next decades look to see more new developments and innovations. With the plastic injection molding industry being one of the largest manufacturing industries in the world, utilizing robotics will help them create efficient and safer ways to manufacture products.

One of the biggest benefits that robotics can provide in the plastic injection molding industry is process automation, which means that certain machines and functions would now be automated. A lot of plastic manufacturing machines still require a good amount of human operation, and using robotics will only help streamline this process, and boost production speed and efficiency, while also improving safety.

Robotics has already been utilized in other manufacturing industries and it has been proven that applying these systems have helped their respective industries produce faster, while still meeting quality standards.

Advantages of using Plastics in Robotics

While robotics can help improve the manufacturing capabilities of the plastic injection molding industry, using plastic parts in robotics also has its own set of benefits that can improve their quality and performance. Here are some of the other advantages that plastic can provide in robotics.

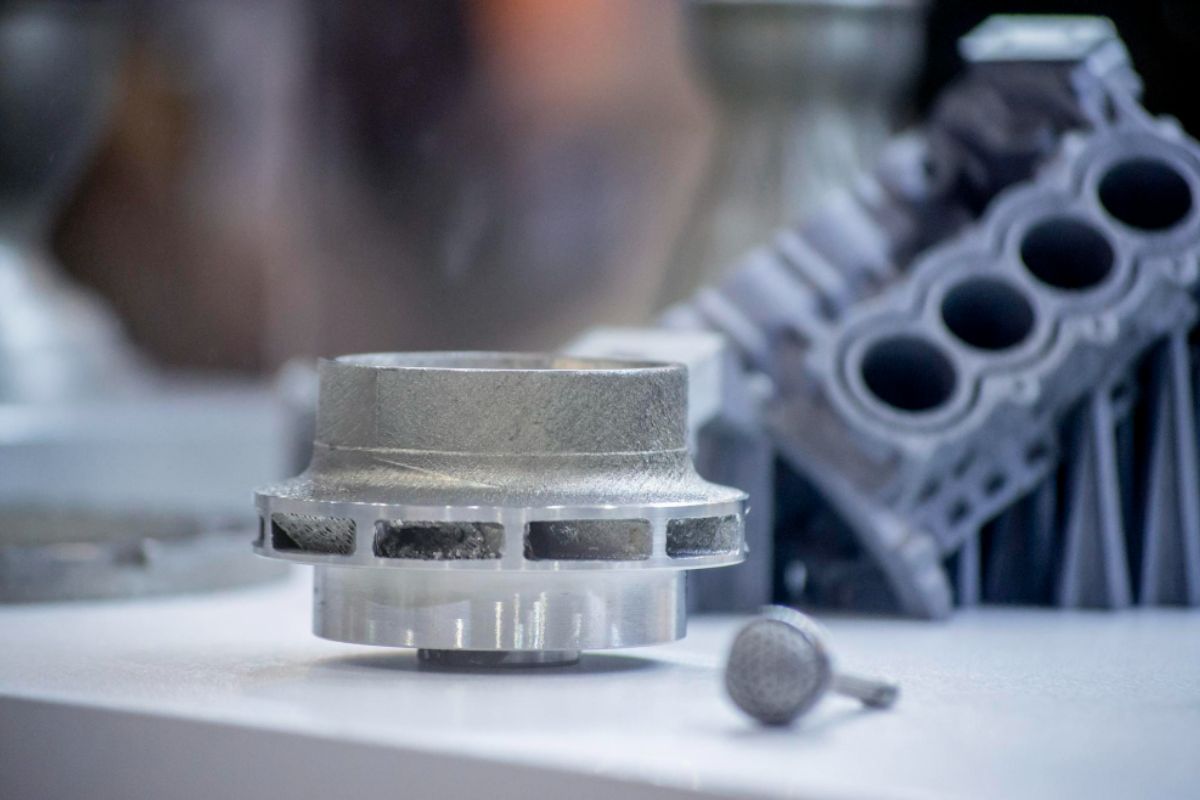

Cost-efficient

The use of plastic parts in manufacturing robots not only helps speed up production, but it is also a more cost-effective option compared to using other materials. Plastic is one of the most abundant resources on the planet. Which is why using them to create different parts for robots is one of the best options. If you are looking to reduce production costs, while improving the speed and efficiency of manufacturing, it is best to use plastic.

Improved Product Quality

Along with being more efficient in manufacturing, using plastic can also help improve the overall product quality. Plastic is one of the best materials for a number of robotic parts thanks to being a common material which is lightweight and durable. Plastic is already used for a wide variety of sophisticated and expensive technology, and being used in robotics is another application where it can be useful and effective.

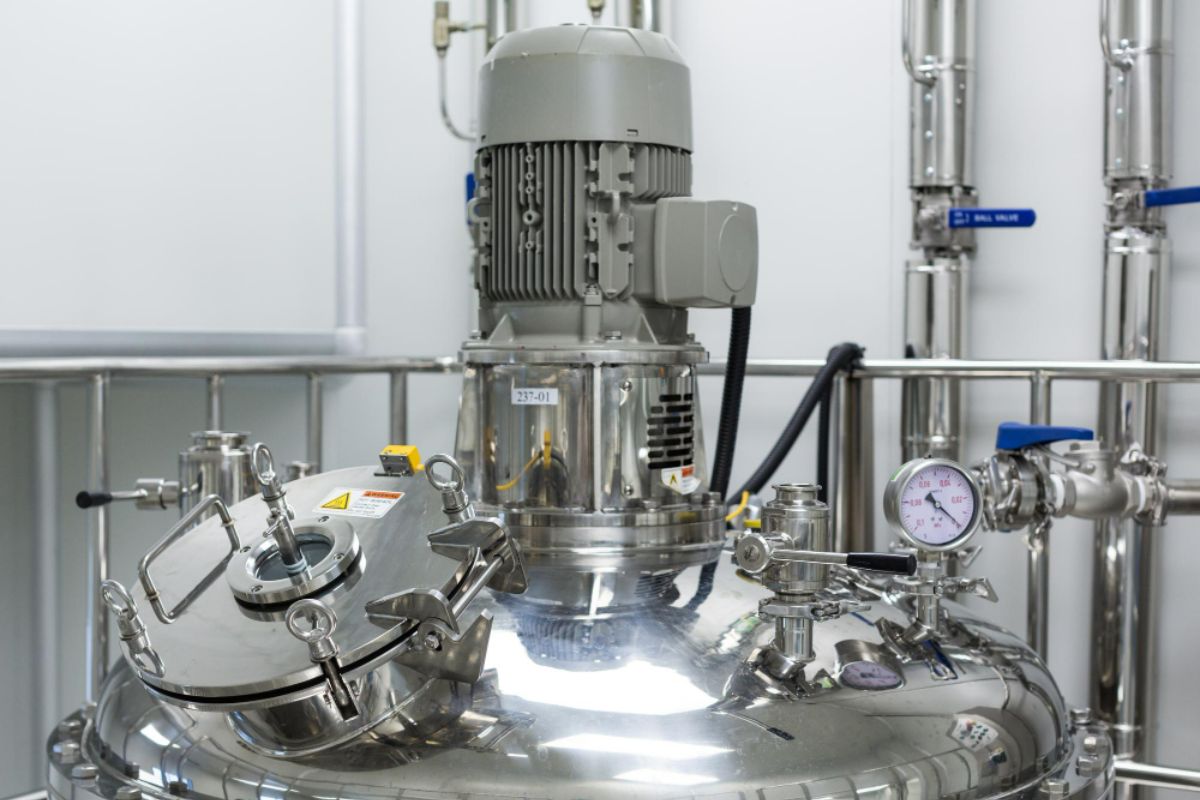

Flexibility and Adaptability

Plastic is one of the most versatile materials around, as they can be molded and shaped into different forms. This makes them ideal for the robotics industry, as they would need an adaptable material that can adjust to the changing needs of machines. This allows companies to be able to quickly craft and shape plastic parts without having to worry about the material’s durability.

Key Takeaway

Robotics continues to be at the forefront of technological and manufacturing innovation and development. By utilizing this technology in the plastic injection molding industry, companies would be able to produce products faster and more efficiently, while automating much of the process gradually.