What are the differences between multi-cavity molds and family molds?

- Type of Mold

- Quantity Per Cycle

- Lead Time

- Tooling Cost

- Price Per Part

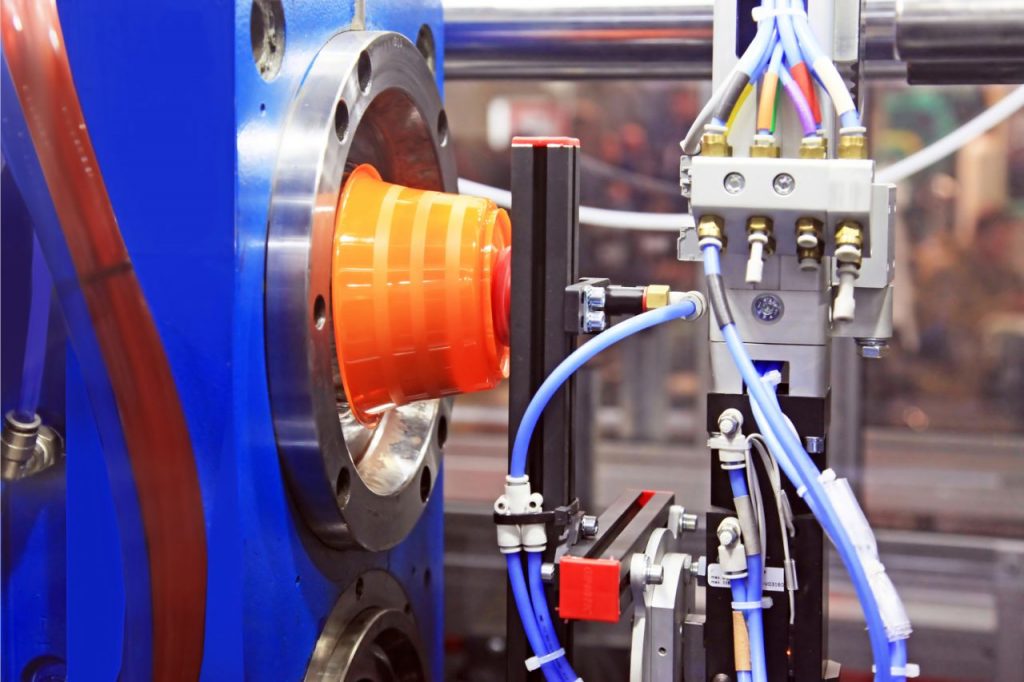

One of the most popular methods of plastic manufacturing is injection molding. The process is just so versatile, that it has produced many products used in a range of industries. This has been made possible through the mold, or mould component of the injection molding machine. In fact, between multi-cavity molds vs family molds, prototyping services in China and in other countries have been debating which of the two is the most suitable for various molding operations. After all, each has its own advantages and disadvantages. Continue reading to learn more.

Type of Mold

The type of mold is one of the major differences between a multi-cavity and a family mold. Simply put, multi-cavity molds refer to molds that have different types of cavity, or hollow spaces. These cavities generally come in similar shapes and sizes, for the purposes of manufacturing multiple plastic parts of the same kind.

Family molds also have multiple cavities in the tooling component, however, the main difference is that the cavities come in differentiated shapes and sizes. For example, after a single production cycle has completed, the production of bottle caps alongside similar-sized products that come in a different design is possible.

Quantity Per Cycle

Overall, the multi-cavity and family molds can both produce the same quantity of plastic products in each cycle, but this ultimately depends on the design. Each cycle for both processes is capable of coming up with multiple plastic components, depending on the structure of the mold.

As you may know, an injection tooling machine is composed of these basic components, the feeder or the hopper, barrel, rotating screws, nozzle, and the mold system. A plastic resin that comes in pellet form is fed into the hopper. As the pellets are rotated through in the barrel, they’re constantly heated in order to melt them before they’re conveyed into the molding plates.

The molding plates can either be multi-cavity or family, depending on the size, but there’s no considerable difference in which type of mold can produce the greater number of ejected injection molding parts.

Lead Time

In manufacturing, the lead time is easily defined as the duration that takes place from the beginning of a process up until the final stage. With this in mind, manufacturing techniques that take place in a much shorter duration is always preferable over those that take more time before the post-processing or the completion stages.

Because multi-cavity molds are capable of producing the same kind of plastic item, this process generates a much faster and shorter lead time compared to family molds. This means that completing each production cycle or batch, can be done in a much faster way, allowing manufacturers to produce a higher yield and increase overall production capacity.

While it may be possible to create differentiated plastic components of the same size with the family molds, the lead time is much longer. Due to the slower process, lower-tier suppliers or manufacturers may begin considering the faster molding method.

Tooling Cost

Multi-cavity molds and family molds are also comparable with their tooling costs. In fact, they’re both advantageous compared to single-cavity molds that may not necessarily be practical to use in injection molding machines because of the cost.

Industries who need plastic parts for their products can either choose between these two types of molds because of the low tooling cost. Likewise, manufacturers have very little problem with accommodating either of these requests. They don’t have to acquire multiple stainless steel or steel molding plates just to produce many products in separate cycles.

Although the tooling costs may be low, both multi-cavity and family molds can be used to come up with products that have the same color in one production process.

Price Per Part

Businesses who may require prototyping services need to ensure that all the third-party services they’re using can provide them with cost-effective solutions. Between the two mold types, multi-cavity molds can result in plastic parts that are far cheaper and more affordable compared to the products made as a result of the family molds. Here’s why.

As mentioned before, the molding plates used in the injection molding process are usually made out of steel or stainless steel — although the latter may be more expensive. These plates need to have multiple cavities or hollow spaces fabricated on them, which will serve as spaces where the molten plastic will fill and solidify during injection molding.

Fabricating each plate to achieve the same design for a plastic component is faster and therefore cheaper across many multi-cavity molds. Creating the grooves and hollow areas for different-sized molds takes a lot more skill and this in turn can increase the price for each part produced from family molds.

Key Takeaway

In the debate between multi-cavity vs family molds, much discussion has been made as to which option is more practical. Although multi-cavity-molded plastic components can be finished more quickly, the price per part may be more expensive. Family-molded products may be cheaper, but they’re not necessarily practical for parts that require variation.

These two molds each have their own advantages and disadvantages. To choose the right one, it’s important to understand your injection molding requirements. Ask yourself if you can work with a molding type with a short lead time, low tooling cost, cheap price per part, or quantity per cycle.