How do I choose between modifying vs building new injection molds?

- Cost

- Modification limitations

- Age and wear of the mold

- Parting lines

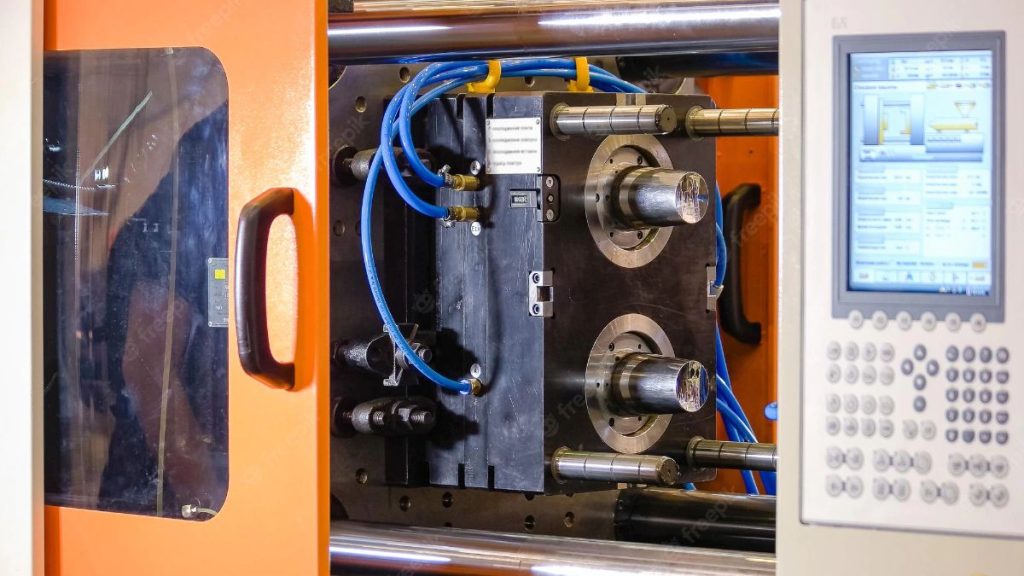

Any business that has undertaken an injection molding project knows that, as their product evolves, so do the tools used to make them.

When you need to adjust the size, design, or part function, you’ll have to tweak your injection molding process. In doing so, you’ll have to decide how these changes will be made — which raises the question: do you modify your molds, or make new ones altogether?

If you’re faced with this decision, we can help. Here is our guide on how to choose between modifying vs building new injection molds:

Cost

In many cases, using either a new or modified injection mold can get the job done. However, you should know that the cost of creating a new injection mold is higher than simplifying an existing one. Even making simple molds can easily run up to thousands of dollars. This cost will increase depending on the size and design of the part.

In comparison, modifying a mold can save you significant time and money. However, that depends on the complexity of the modifications you are making. Some design changes can also be expensive, due to the long lead times it’ll take to accommodate your modifications. Some modifications can take up to weeks to complete, which will negatively affect your production and revenue streams.

Regardless of the decision, you have to weigh the return on investment you’ll get for each choice. If you’re making big changes to your product, then making a new mold may be more cost-effective. Likewise, smaller design changes may justify the cost and lead time you’ll take with mold modifications.

Modification limitations

Modifying an existing mold, as we said, tends to be the less expensive option. However, you should know that there are limitations to what can be modified for any injection mold.

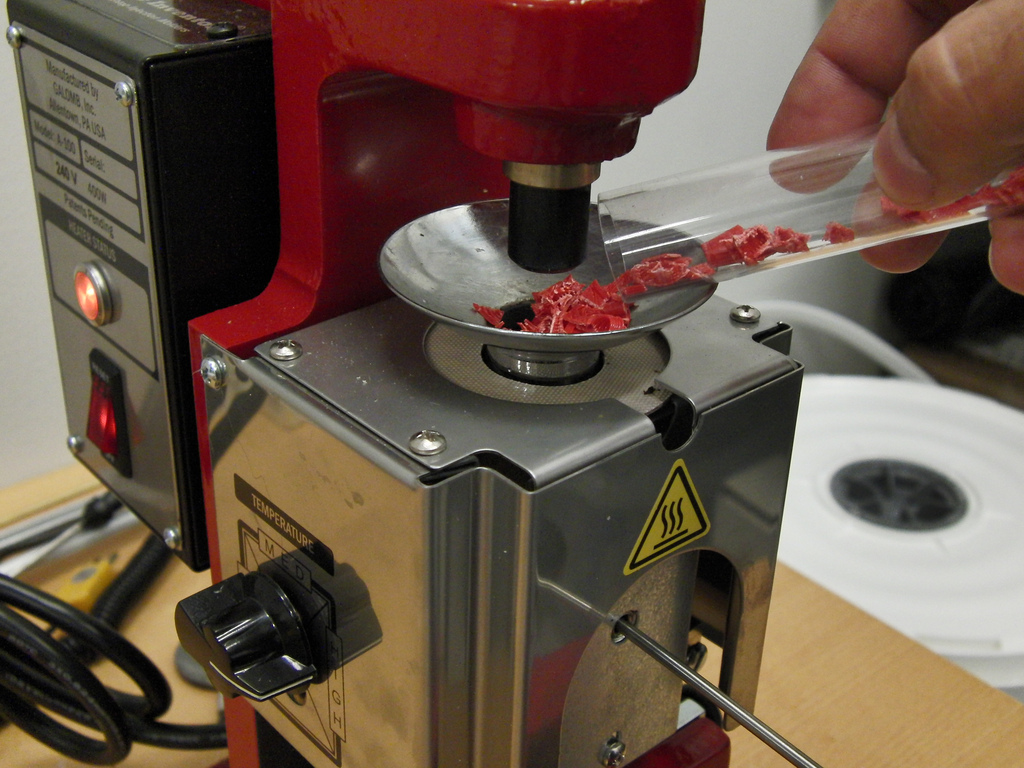

Each modification will require cuts to be made to your existing mold. And, each cutting change can only be done to a certain minimum depth. Any more than this may damage the mold and render it useless. So, you have to check with your mold supplier if these design modifications can be reasonably made.

For mold changes that cannot reasonably be milled, a new mold will need to be made.

Age and wear of the mold

Another consideration to keep in mind is the age of your injection mold. The older it is, then the more wear and tear it has.

If your mold is a few years old or is nearing the end of its usable life, then you’ll likely be better off creating a new mold anyways. The overall cost of doing so may be lower than trying to make modifications to the mold.

Parting lines

Parting lines are what indicate where the two halves of the injection mold meet.

This is an important design consideration when making your mold, as it affects the gate location and venting during the molding process. Additionally, parting lines affect the aesthetics and function of the plastic part.

Making changes to your mold will affect how plastic flows in. This can make mold modifications too broad — or simply impossible for mold makers to accomplish. In some cases, this could require a new mold to be made.

When should I consider modifying my mold?

That said, when is it best to choose modification over making a new mold? If you’re thinking of making the following changes, then modification may be a great option for your project:

- Expand part geometry — Making minimal removals of the mold to increase part size or wall thickness. Depending on how much metal you need to remove, this may be possible through modification.

- Adding a smaller part — In some mold designs, there may be enough extra room to create a small cavity or install a small part to the mold in a similar style. This can be done through a shut-off separation from the main cavity.

- Core replacement — If you need the plastic part to be smaller, but retain the same qualities and general shape of the original design. The mold can be kept as is while the core is replaced.

As you can see, small adjustments and tweaks can easily be accommodated into most mold designs. However, always consult your supplier if you want to see if modification is right for you.

When should I consider building a new mold?

Although more expensive, there are some cases where making a new mold would be more efficient than modifying one. They are:

- Shrinking a part — When you need to minimize your plastic part at multiple dimensions. This is more complex, so core replacement is not an option. And, new metal can’t be added to an existing mold, so you’ll need to make a new mold.

- Changing the resin — using a different resin will result in different flow and shrink rates. Molds are designed with a specific resin material in mind, so changing your resin selection will require building a new mold.

- Parting line change — Changing part design at the parting line often requires a new mold design. Doing so will help prevent venting and gating problems.

While the initial price of this choice can be daunting, there are a few cases where creating a new mold altogether is more cost- and time-effective in the long run.

Key Takeaway

Choosing between modifying vs building new injection molds is a big decision that will impact your production — and in turn, your business and customers. So, it’s important to know how to make the right choice in this situation.

Whichever one you choose, Richfields’ experts can help. We are a trusted plastic mold maker and have the capabilities for making and modifying molds and have years of experience in both fields. Contact us today, and our team will be happy to help fulfill your injection molding needs!