What industries apply plastic injection molding for their products in the USA?

- Construction

- Electronics

- Food and beverage

- Agriculture

- Household

- Architecture

- Toys and novelties

Plastic components are valuable across industries due to their immense versatility. Precision plastic injection molding stands out because it enables businesses to meet specific needs and exacting standards.

At Richfields, we take pride in being China’s leading and trusted plastic injection molder. With our cutting-edge methods and technologies at our disposal, we can develop precise plastic products not just in China, but also to our clients in the USA.

This blog post discusses various industries that use plastic injection molding in the USA. Read on to learn more.

Construction

Regarding building materials, we often think of steel and concrete as the go-to options. However, there are situations where using plastic can be a better and safer choice. Let’s take the example of a window frame made of plastic.

In countries like the USA, manufacturing industries are generally recommended to use plastic resins for their materials.

One such type of plastic resin is uPVC (unplasticized polyvinyl chloride). This resin is known for its excellent thermal insulation properties. It has a low thermal conductivity as well, which means it’s less likely to transfer heat or cold from the outside to the inside, helping to maintain indoor temperature and reduce heat loss during colder weather.

On top of that, window frames made of plastic are less expensive, making plastic a cost-effective choice for many projects.

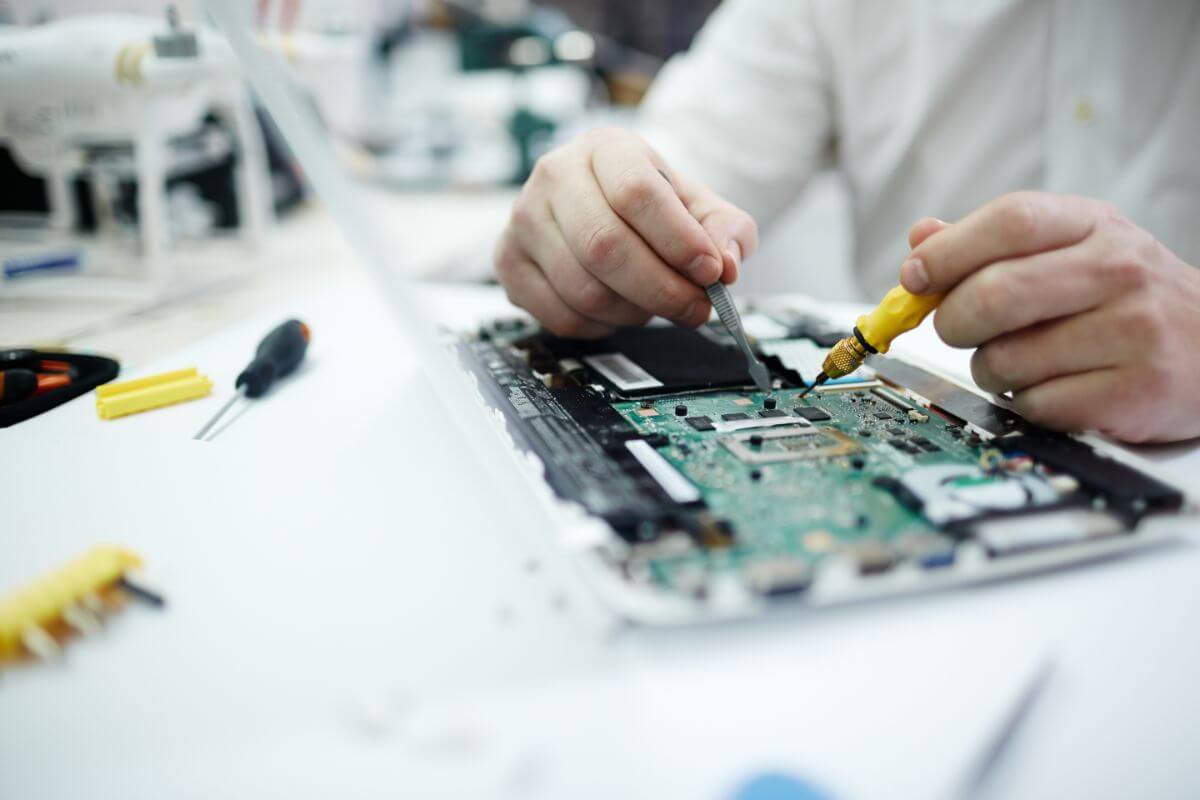

Electronics

The consumer electronics market in the USA is expected to experience a steady growth rate of 1.18% between 2023-2028. By 2028, it’s estimated that the market volume will reach an impressive US$164.40 billion.

This reflects the increasing popularity of devices, such as smartphones, laptops, televisions, and other gadgets in the USA. That’s why many companies are constantly striving to develop cutting-edge plastic cases for these devices.

Without these cases, these devices would be scattered and connected, making the device unusable. Therefore, think of it as the skeleton or structure that keeps everything in place. It offers a pleasing aesthetic finish while holding the device, too.

Moreover, it acts as a barrier against dust, moisture, and other potentially damaging factors that could affect the electronics. Thus, it helps ensure the longevity and functionality of the device as well.

Food and Beverage

In the food and beverage industry in the USA, plastic materials are widely used for creating packaging and containers through a process called plastic injection molding.

For instance, plastic materials can be molded to be free of BPA (Bisphenol A), which is a chemical that some studies have linked to potential health risks. Additionally, they must be certified by the FDA (Food and Drug Administration) as safe for direct contact with food, ensuring that they meet the necessary regulatory standards.

Another important aspect is that the plastic materials used in injection molding are non-toxic, meaning they do not release harmful substances that could contaminate food or beverage products, which ensures the safety and well-being of consumers.

Agriculture

The agriculture industry in the USA utilizes machinery and equipment made from precise plastic materials. That just shows that plastic offers numerous advantages and suitability for specific applications.

For instance, plastic-made machinery and equipment are lightweight compared to ones made of metal, making them easier to handle and transport. This is particularly beneficial for equipment such as irrigation systems, pipes, and portable farm tools.

Plastic machinery is also resistant to corrosion and rust, which is essential in agricultural environments where equipment comes into contact with moisture, chemicals, and fertilizers. Additionally, it can be designed to be UV-resistant, ensuring durability even when exposed to sunlight.

Household

Injection molding has made it possible to produce these household items on a large scale, making them more accessible and affordable for consumers. By using molds and injecting molten plastic into them, many companies in the USA can supply identical copies of their household products efficiently.

Additionally, the advantage that injection molding brings is it allows for the mass production of plastic-made household products. This means that hundreds can be made in a relatively short period. This hikes up the supply to meet the demands of customers, making the products more affordable in the process.

Architecture

Plastic injection molding is a manufacturing process that can bring architectural parts to life while ensuring high-quality results at a reasonable cost.

By utilizing this method, the architecture industry can create custom architectural components according to specific requirements. Whether clients need window frames, hinges, handles, or other parts, the process allows for precise and detailed production.

On top of that, it also offers excellent weather resistance and thermal characteristics. The materials used, such as UV-inhibited engineered nylon, celcon, polypropylene, and vinyl are specifically chosen for their ability to withstand outdoor elements and temperature changes.

Toys and Novelties

Finally, the toy manufacturing industry in the USA is known for its long history of producing toys and is home to several well-known companies. For them, metal is not a practical choice and materials like clay can be too fragile. That’s why plastic is the ideal medium for producing toys. It allows for precise manufacturing and ensures that the toys are durable and long-lasting.

For this reason, their toys have undergone plastic injection molding to help them bring their creative toy ideas to life and deliver toys that are both safe and enjoyable for children.

Key Takeaway

With all of these industries that use plastic injection molding in the USA to create their products, companies need to ensure that they have the best possible manufacturing process for incredibly intricate designs.

If you’re looking for a plastic injection molder, you’re in the right place. Richfields Corporation is a China-based injection molding company that offers full-service injection molding services for USA companies. We have the best solutions and experience needed to improve your production. For inquiries, contact Richfields Corporation here.